Energy self-sufficient type modular spliced deep sea fishery breeding work ship

A deep-sea fishery and modularization technology, which is applied to ship parts, ship construction, and ship motion reduction, can solve the problems of hull longitudinal bending strength threat, large wave additional bending moment and shear force, unfavorable growth of farmed fish, etc., to achieve increased Seawater exchange rate, good longitudinal bending moment and transverse and longitudinal shear force, effect of good water exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

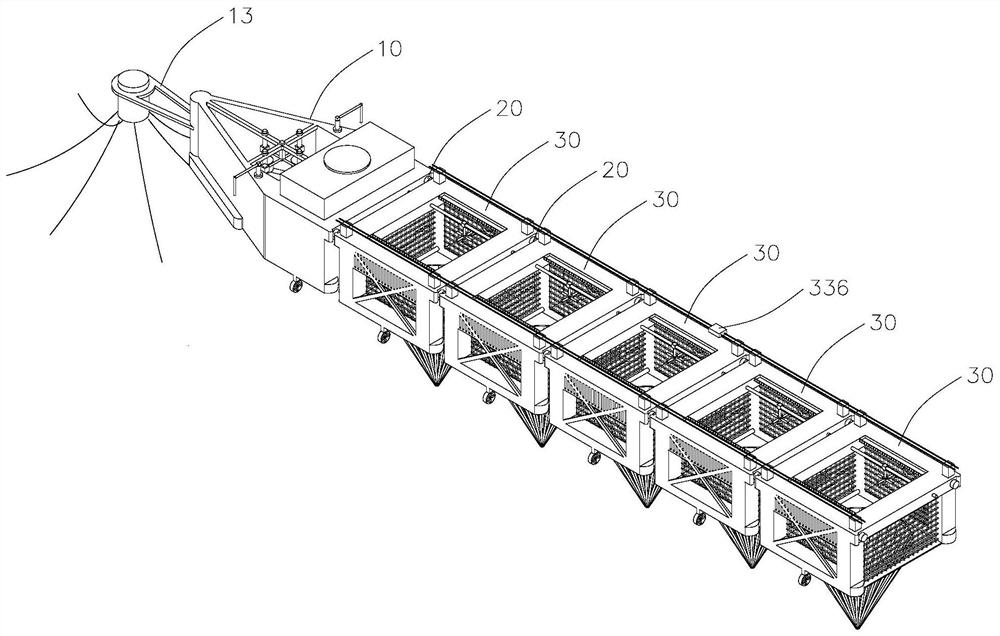

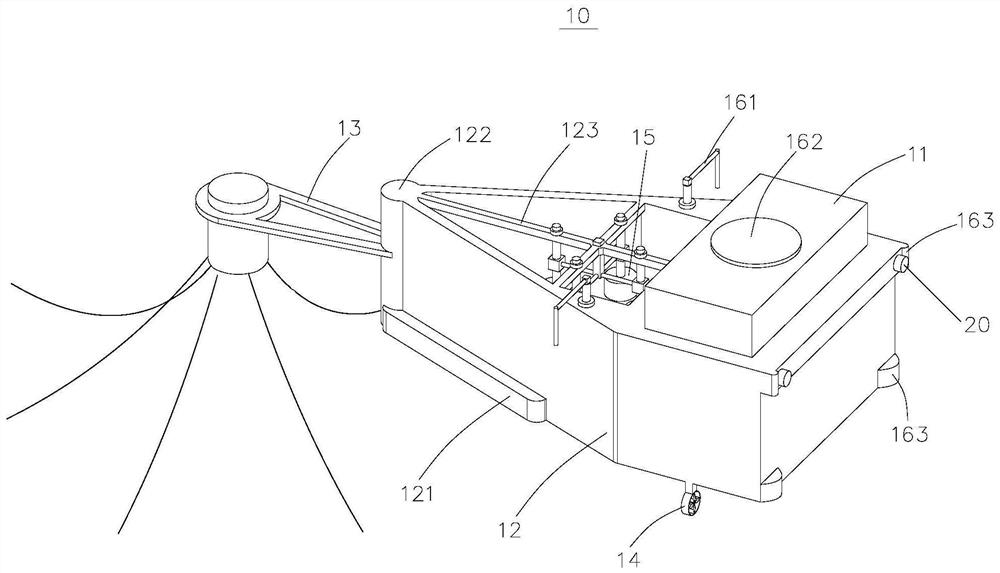

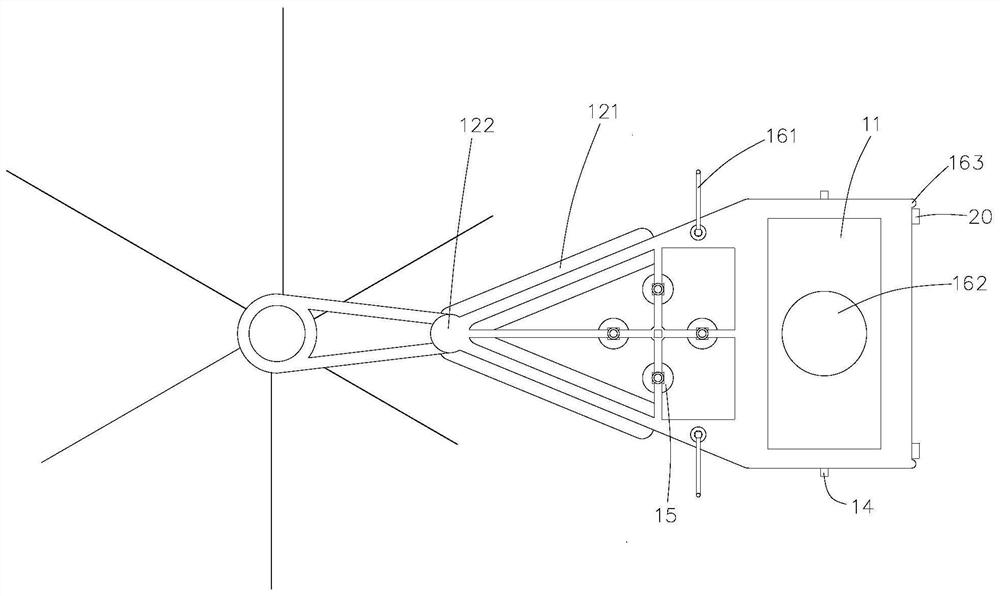

[0037] like figure 1 As shown, an energy self-sufficient modular splicing deep-sea fishery breeding work vessel provided by an embodiment of the present invention includes a semi-submersible bow 10, several flexible connection devices 20 and several semi-submersible modular net cages 30. Among them, the semi-submersible bow 10 is used to provide electric power for the farming ship, provide a ship driving area, a crew living area, a fish processing storage area, and a feed storage area, and provide berthing devices and mooring of the entire ship for other ships. The semi-submersible modular net cage 30 is arranged successively along the length of the ship, and the flexible connection device 20 is used for the connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com