Preparation method of octadecanedioic acid mono-tert-butyl ester-PFP

A technology of octadecanedioic acid and mono-tert-butyl ester, which is applied in the field of pharmaceutical preparation, can solve the problems of low purity, difficult coupling of tert-butyl ester, and unsuitability for popularization of production, and achieve simple post-processing and high reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

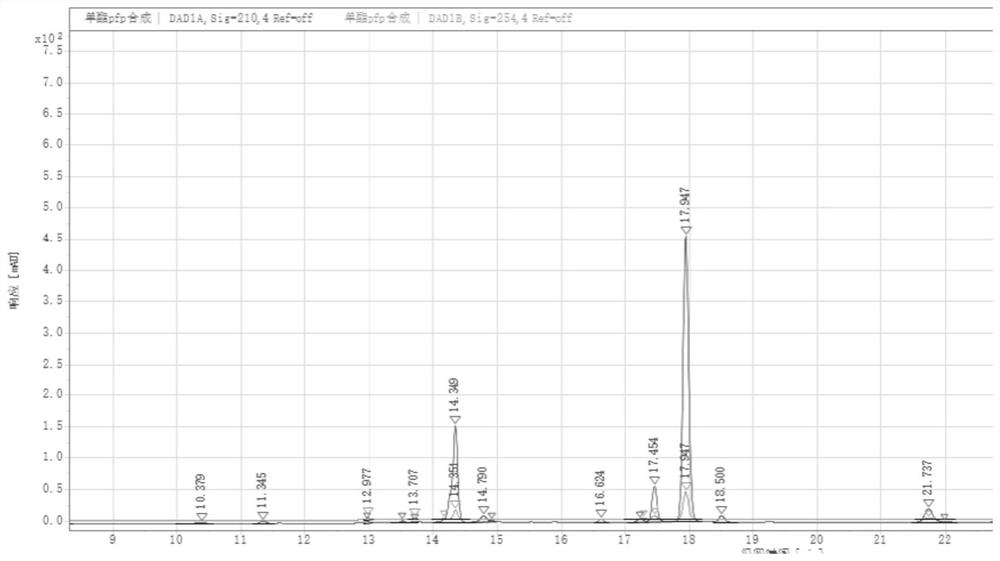

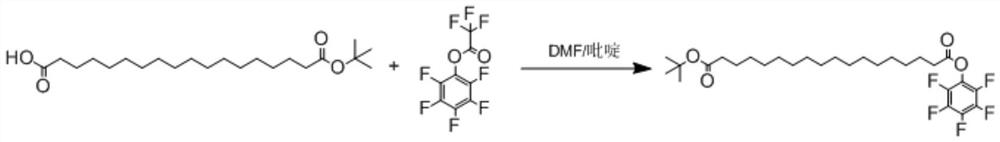

[0032] Such as figure 1 As shown, the present invention provides technical scheme, a kind of preparation method of mono-tert-butyl octadecanedioate-PFP,

[0033] Including the preparation of compound 1 and the preparation of mono-tert-butyl octadecanedioate-PFP;

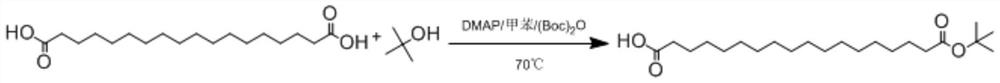

[0034] Wherein the preparation of compound 1 comprises the following steps:

[0035]

[0036] S1. In the reaction kettle, add octadecanedioic acid, toluene, tert-butanol, start stirring, add (Boc) after heating 2 O reaction was stirred at room temperature overnight;

[0037] The reactor of S1 in compound 1 is 50L, the heating temperature is 70 degrees, and the reaction time is 4.5h;

[0038] S2, post-processing: 10L of reaction solution is decompressed and rotary evaporated to 5L, added DCM solution to dilute to 10L, washed with 10L of water, filtered and separated to keep the organic layer, then washed with 10L of 5% phosphoric acid aqueous solution and separated to keep the organic layer, Finally, wash the s...

Embodiment 2

[0055] Such as figure 1 As shown, the present invention provides technical scheme, a kind of preparation method of mono-tert-butyl octadecanedioate-PFP,

[0056] Including the preparation of compound 1 and the preparation of mono-tert-butyl octadecanedioate-PFP;

[0057] Wherein the preparation of compound 1 comprises the following steps:

[0058]

[0059] S1. In the reaction kettle, add octadecanedioic acid, toluene, tert-butanol, start stirring, add (Boc) after heating 2 O reaction was stirred at room temperature overnight;

[0060] S2, post-processing: 10L of reaction solution is decompressed and rotary evaporated to 5L, added DCM solution to dilute to 10L, washed with 10L of water, filtered and separated to keep the organic layer, then washed with 10L of 5% phosphoric acid aqueous solution and separated to keep the organic layer, Finally, wash the separated liquid with 10L saturated brine and keep the organic layer;

[0061]S3. The organic layer is decompressed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com