Synthetic method of efficient high-stability catalyst for aqueous phase click reaction

A high-stability, click-reaction technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems affecting reaction activity and achieve high catalytic activity , less dosage, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for synthesizing an efficient and highly stable aqueous phase click reaction catalyst, the steps are as follows:

[0044] (1) Add 20mL of anhydrous tetrahydrofuran to a dry 100mL round-bottomed flask, add 2mL of trimethylsilylacetylene; cool the system to -70°C under nitrogen protection, and slowly add 2.4mol / L of n-butyl lithium dropwise to it Solution 6mL, stirring reaction 5h;

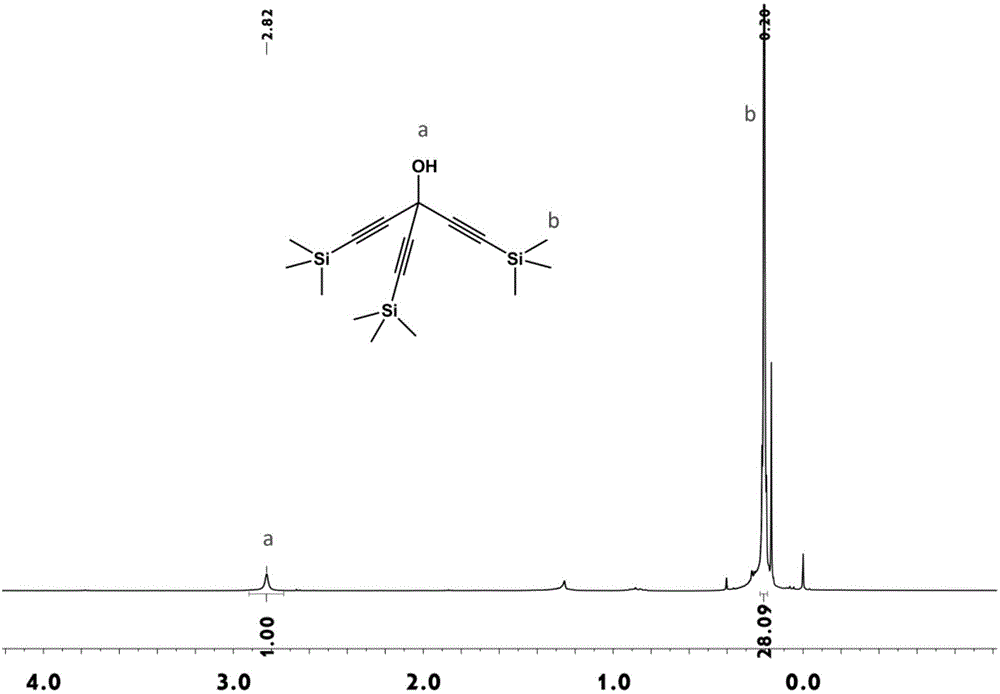

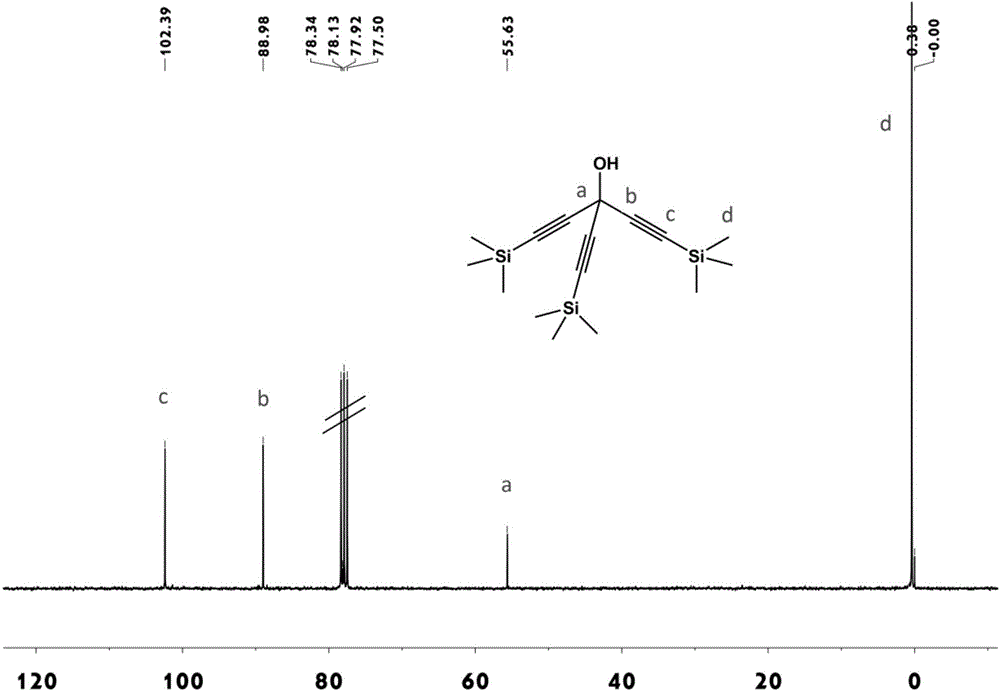

[0045] (2) Add 0.4 mL of the compound (ethyl chloroformate) represented by formula (I) to the solution obtained in step (1), and allow it to recover to -30°C naturally, and react for 15 hours; after the reaction, use ammonium chloride to saturate The solution quenches the reaction, and the reaction product is extracted 3 times with ether, and the organic phases are combined, dried and concentrated to obtain a crude product; the crude product is separated using a silica gel column to obtain the compound shown in formula (II);

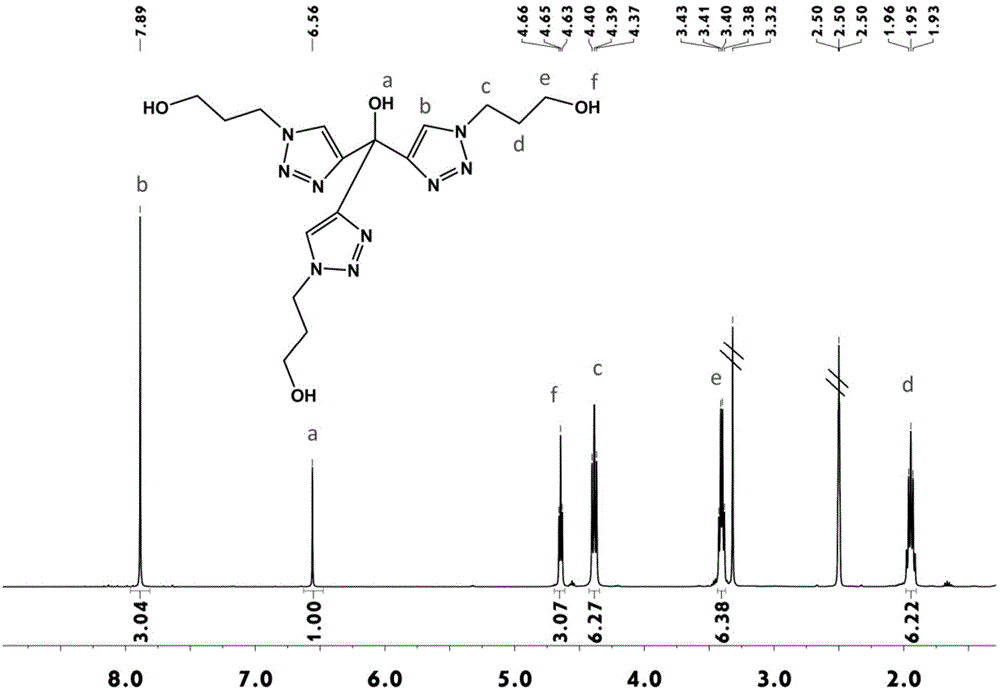

[0046](3) Dissolve 0.5 g of the compound represented by ...

Embodiment 2

[0050] A method for synthesizing an efficient and highly stable aqueous phase click reaction catalyst, the steps are as follows:

[0051] (1) Add 100mL of anhydrous tetrahydrofuran to a dry 250mL round-bottomed flask, add 12mL of trimethylsilylacetylene; cool the system to -78°C under nitrogen protection, and slowly add 2.4mol / L of n-butyl lithium dropwise to it 35mL, stirred and reacted for 8h;

[0052] (2) Add 2.1mL of the compound (ethyl chloroformate) represented by formula (I) to the solution obtained in step (1), and allow it to recover to -30°C naturally, keep this temperature and react for 20h; after the reaction, Use ammonium chloride saturated solution to quench the reaction, the reaction product is extracted 3 times with diethyl ether, the organic phases are combined, dried and concentrated to obtain a crude product, which is separated by a silica gel chromatographic column to obtain a compound shown in formula (II);

[0053] (3) Dissolve 2 g of the compound repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com