Dry-wet combined maintenance method for process cavity of semiconductor film forming APCVD machine

A dry-wet combination, process chamber technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve problems such as semiconductor silicon wafer process defects, reduce defective scrap rate, ensure stability, increase The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

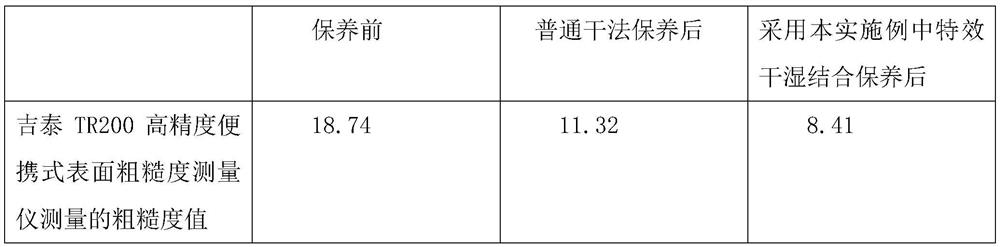

[0022] The maintenance method of dry-wet combination of semiconductor film-forming APCVD machine process chamber, the specific steps are as follows:

[0023] First of all, prepare special maintenance equipment for maintenance, including: special nozzles for dry corrosion, special Teflon bellows, self-made brushes for cleaning, and special Teflon air pipes.

[0024] Wet corrosion: Lay a clean cloth on the floor in the process chamber of the machine, use multiple clean cloths to overlap and place them on the edges of both sides of the floor directly below the installation position of the special nozzle. Avoid splashing too much hydrofluoric acid during wet process, which will flow into the inside of the machine and corrode the machine. The plane between the process chambers of adjacent machines is paved with clean cloth. After wearing protective labor protection articles, pour hydrofluoric acid in an amount of 160 ml per square meter, so that the dust-free cloth contains a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com