Ridge type demister capable of recycling flushing water, demisting system and wet desulphurization system

A technology of demister and flushing water, which is applied in the field of demist system, wet desulfurization system and roof type demister, which can solve the problems of large space occupation and difficult project implementation, and achieve good integrity and few parts , Efficient recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

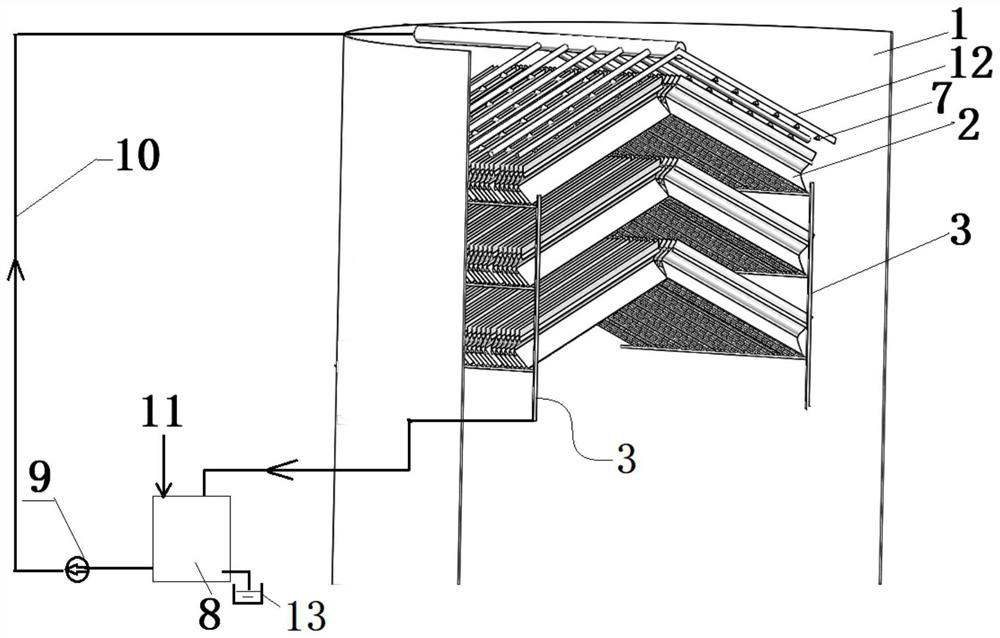

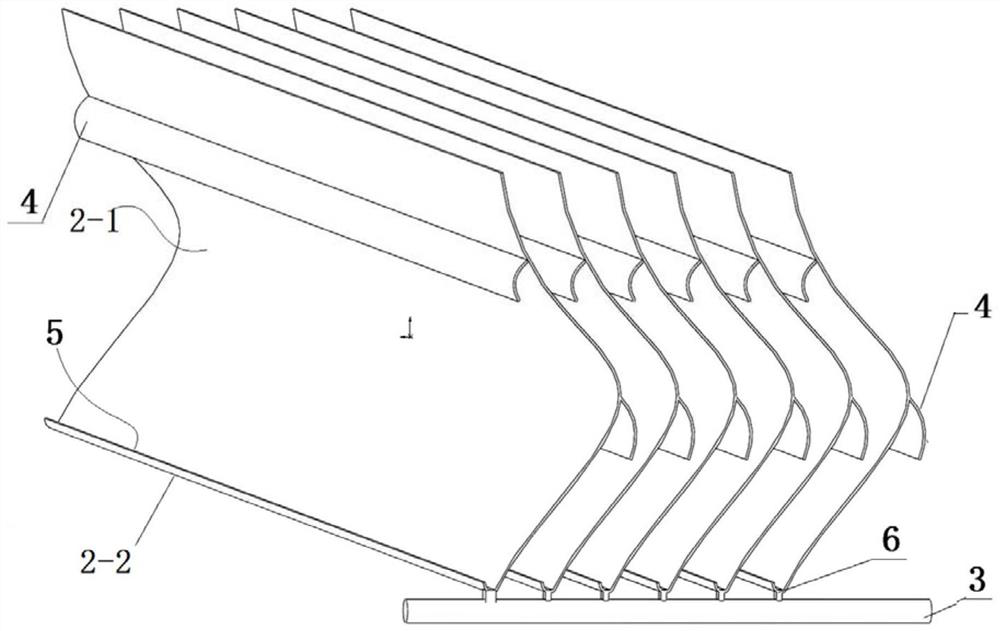

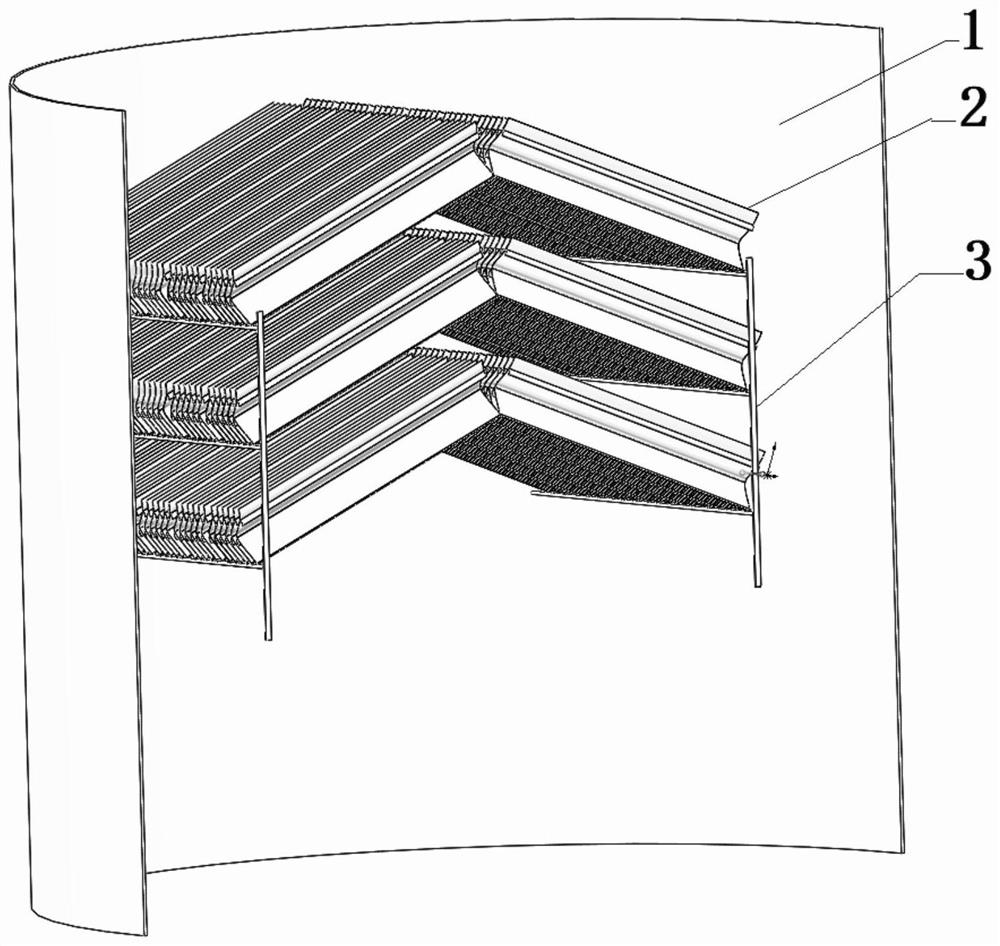

[0038] refer to Figure 1-Figure 3The wet desulfurization system of the present invention comprises an absorption tower 1, a roof type demister 2, a flushing water confluence pipe 3, a demister flushing device 12, a flushing water recovery tank 8, a demister flushing pump 9, a flushing water pipeline 10 and The process water replenishment pipeline 11, wherein the demister blade 2-1 is provided with a channel 4, a recovery tank 5 and a drainage tank 6; the demister flushing water device 12 includes a demister flushing water pipeline 10 and a demister flushing Nozzle 7, flushing nozzles are evenly arranged above the demister to achieve efficient flushing of the demister.

[0039] The roof type demister 2 generally includes an inlet section, a demister channel and an outlet section. The outlet section is composed of the outlet sections of two adjacent defogging blades, and the inlet section, the defogging channel and the outlet section are connected by this. A water collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com