Method for removing trivalent antimony in aqueous solution by using chitosan modified biochar

A technology of chitosan modification and biochar, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of insufficient removal rate and weak adsorption capacity of trivalent antimony, and achieve the cost of preparation Low, method safety, and the effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method utilizing chitosan modified biochar to remove trivalent antimony in aqueous solution, comprising the following steps:

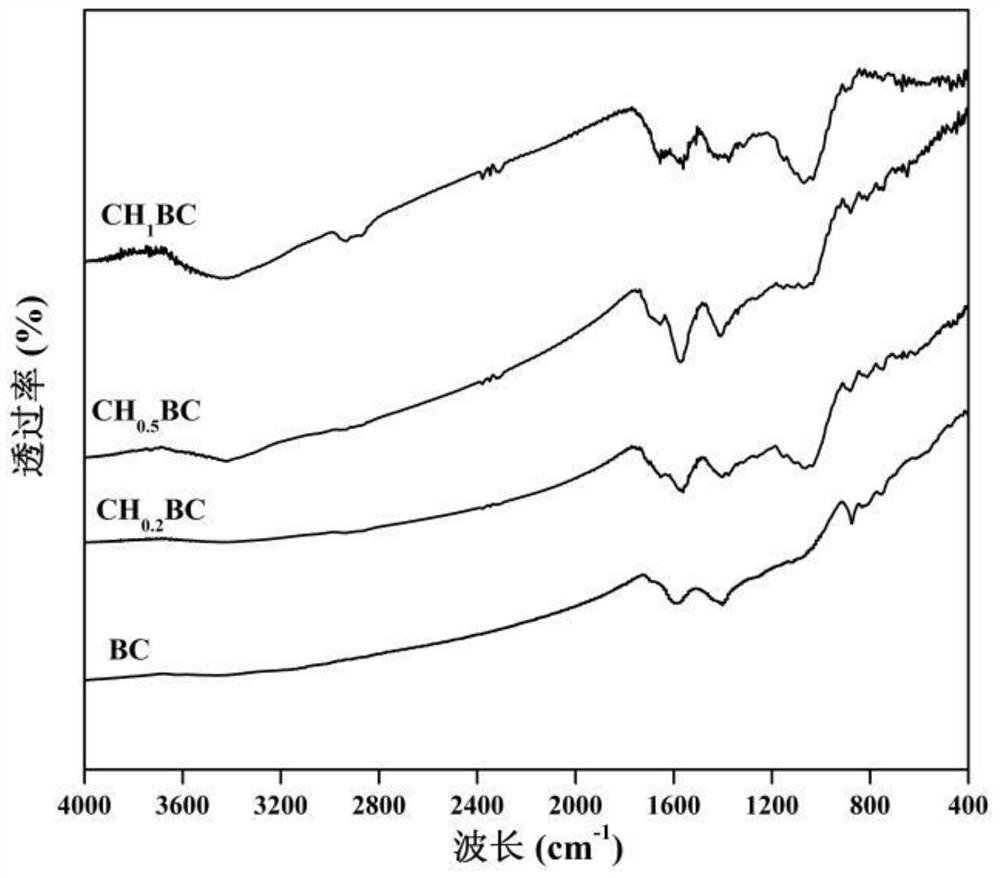

[0035] Step 1: After pulverizing, sieving and drying the ficus ficus branches, the dried material is subjected to nano-grinding treatment to obtain nano-powder. When performing nano-grinding treatment, a large amount of mechanical energy is applied to the material to change the crystal lattice and Surface properties, so that it is in an activated state, the nano-powder is heated to 500°C at a heating rate of 15°C / min in a pyrolysis device, and then kept for 2 hours, and then taken out after cooling to obtain unmodified biochar;

[0036] Step 2: dissolving chitosan in 2.5% acetic acid solution, the degree of deacetylation of chitosan is above 75%, and ultrasonic stirring until completely dissolved;

[0037] Step 3: Stir a part of the biochar with the above solution for 30 minutes, and ultrasonically mix to obtain a mixed solution;

[0038] Ste...

Embodiment 2

[0042] A method utilizing chitosan modified biochar to remove trivalent antimony in aqueous solution, comprising the following steps:

[0043] Step 1: After pulverizing, sieving and drying the ficus ficus branches, the dried material is subjected to nano-grinding treatment to obtain nano-powder. When performing nano-grinding treatment, a large amount of mechanical energy is applied to the material to change the crystal lattice and Surface properties, so that it is in an activated state, the nano-powder is heated to 500°C at a heating rate of 15°C / min in a pyrolysis device, and then kept for 2 hours, and then taken out after cooling to obtain unmodified biochar;

[0044] Step 2: dissolving chitosan in 2.5% acetic acid solution, the degree of deacetylation of chitosan is above 75%, and ultrasonic stirring until completely dissolved;

[0045]Step 3: Stir a part of the biochar with the above solution for 40 minutes, and ultrasonically mix to obtain a mixed solution;

[0046] Step...

Embodiment 3

[0050] A method utilizing chitosan modified biochar to remove trivalent antimony in aqueous solution, comprising the following steps:

[0051] Step 1: After pulverizing, sieving and drying the ficus ficus branches, the dried material is subjected to nano-grinding treatment to obtain nano-powder. When performing nano-grinding treatment, a large amount of mechanical energy is applied to the material to change the crystal lattice and Surface properties, so that it is in an activated state, the nano-powder is heated to 500°C at a heating rate of 15°C / min in a pyrolysis device, and then kept for 2 hours, and then taken out after cooling to obtain unmodified biochar;

[0052] Step 2: dissolving chitosan in 2.5% acetic acid solution, the degree of deacetylation of chitosan is above 75%, and ultrasonic stirring until completely dissolved;

[0053] Step 3: Stir a part of the biochar with the above solution for 45 minutes, and ultrasonically mix to obtain a mixed solution;

[0054] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com