Dynamic mechanical property testing device for amorphous alloy and method thereof

A technology of dynamic mechanics and amorphous alloys, applied in measuring devices, scientific instruments, strength characteristics, etc., can solve difficult problems such as the study of dynamic mechanical properties of amorphous alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] (1) Preparation of Zr 58 Cu 12 Ni 12 al 15 Nb 3 Amorphous alloy: Zr, Cu, Ni, Al, Nb with purity ≥ 99.99%, 5 kinds of metals are mixed according to the atomic percentage of 58:12:12:15:3, arc melting in a high-purity argon atmosphere, first The Zr-Nb binary alloy is melted, then mixed with other metal elements to melt the master alloy ingot, and then the alloy ingot is melted and poured into a copper mold. The size of the copper mold is Φ5mm*50mm, and the Zr-based amorphous alloy sample is prepared.

[0082] (2) Process the sample into a cylindrical sample 7 of Φ3mm*3mm, use 400#-2000# sandpaper to grind the upper and lower bottom surfaces of the cylindrical sample from small to large, so that the flatness of the two end faces of sample 7 is better than 5 μm, and then Rinse and dry with absolute ethanol.

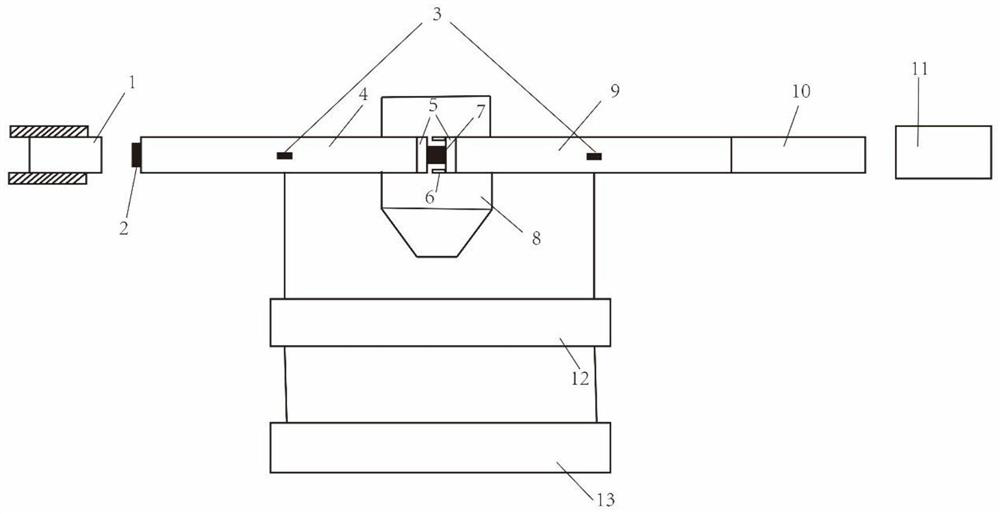

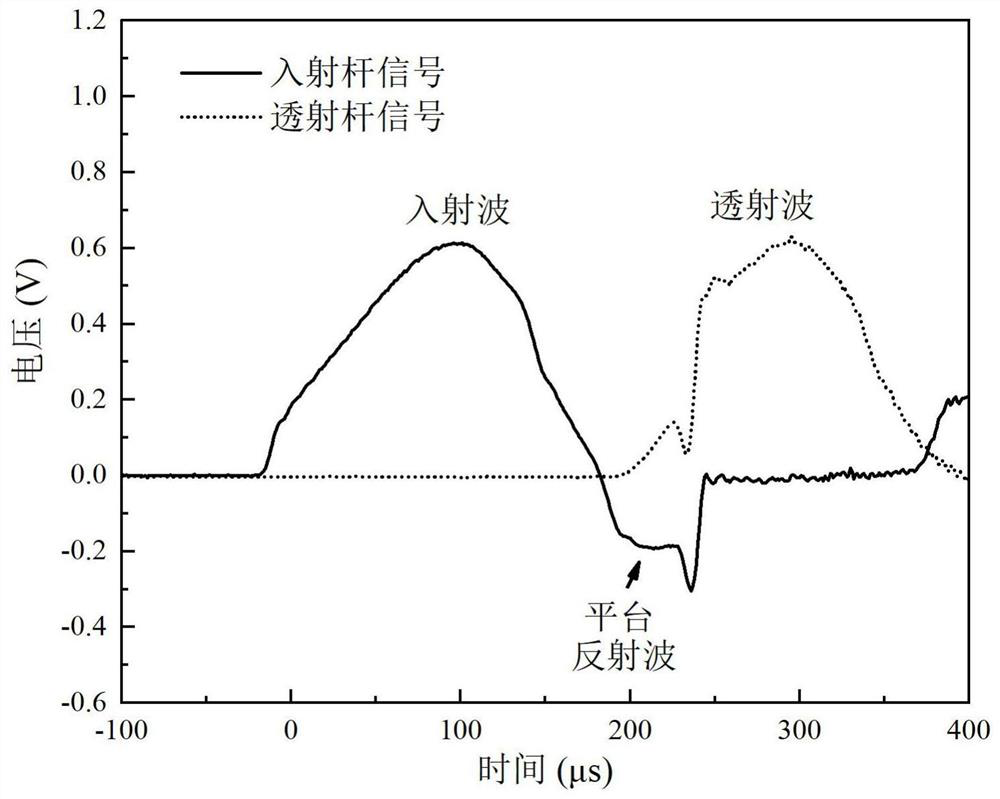

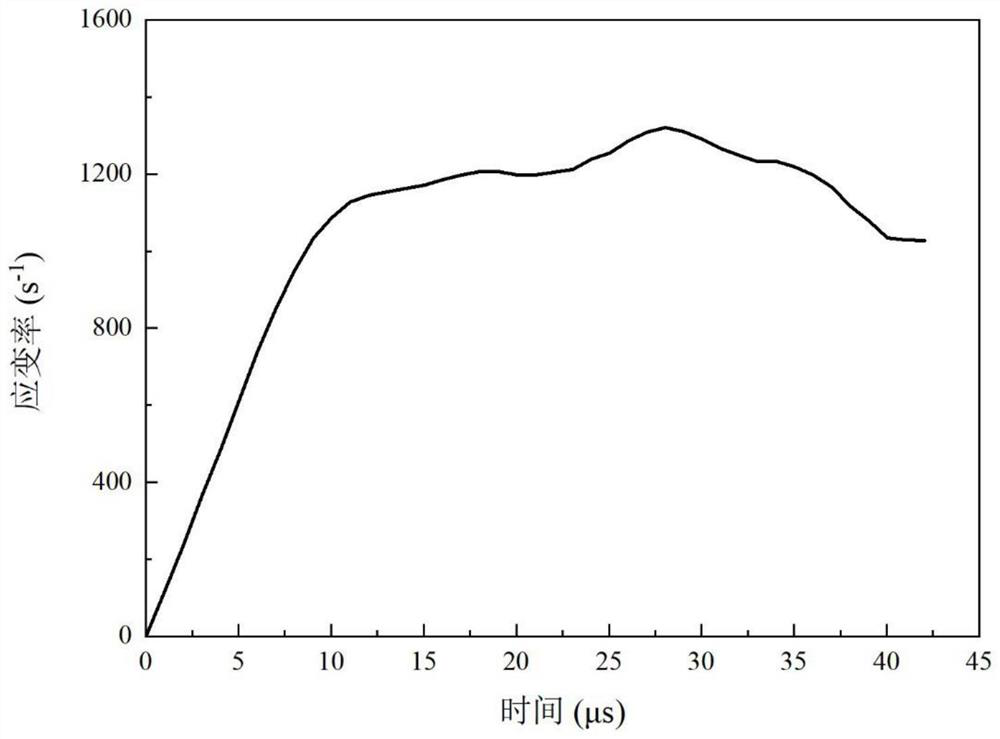

[0083] (3) The sample 7 is placed between the incident rod 4 and the transmission rod 9, and a stop ring 6 made of 18Ni300 maraging steel with an outer diameter o...

Embodiment 2

[0088] (1) Preparation of Zr 63 Cu 12 Ni 12 al 10 Nb 3 Amorphous alloy: Zr, Cu, Ni, Al, Nb with a purity ≥ 99.99%, 5 kinds of metals are mixed according to the atomic percentage 63:12:12:10:3, arc melting in a high-purity argon atmosphere, first The Zr-Nb binary alloy is melted, then mixed with other metal elements to melt the master alloy ingot, and then the alloy ingot is melted and poured into a copper mold. The size of the copper mold is Φ5mm*50mm, and the Zr-based amorphous alloy sample is prepared.

[0089] (2) Process the sample into a cylindrical sample 7 of Φ3mm*3mm, use 400#-2000# sandpaper to grind the upper and lower bottom surfaces of the cylindrical sample from small to large, so that the flatness of the two end faces of sample 7 is better than 5 μm, and then Rinse and dry with absolute ethanol.

[0090] (3) The sample 7 is placed between the incident rod 4 and the transmission rod 9, and a stop ring 6 made of 18Ni300 maraging steel with an outer diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com