Button cell explosion-proof sealing structure, button cell and packaging method thereof

A button battery and sealing structure technology, which is applied to sealing materials, secondary batteries, structural parts, etc., can solve the problems of poor corrosion resistance and short service life, and achieve the effects of compact structure, compact connection and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

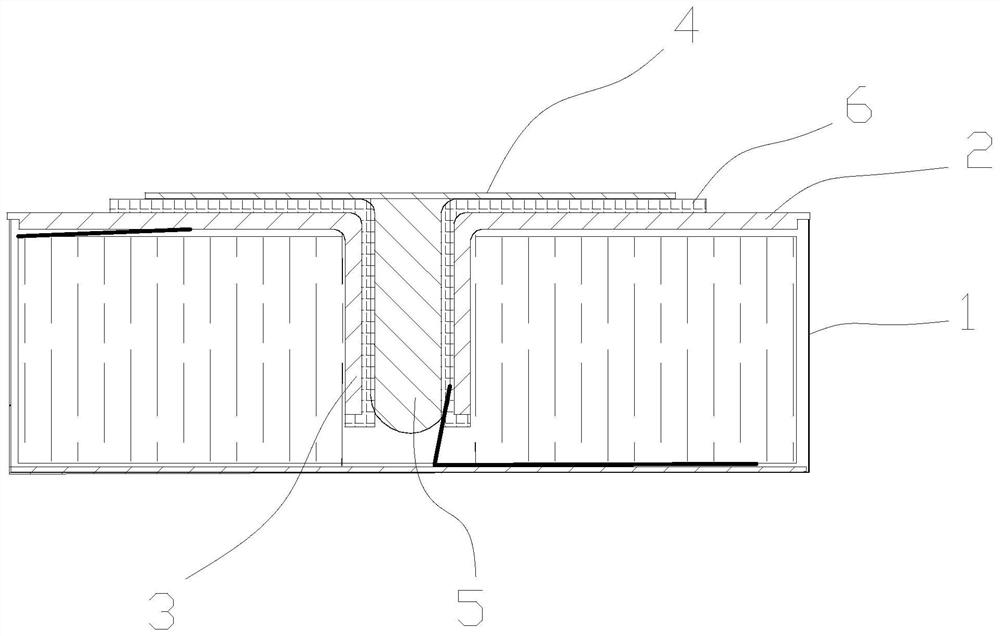

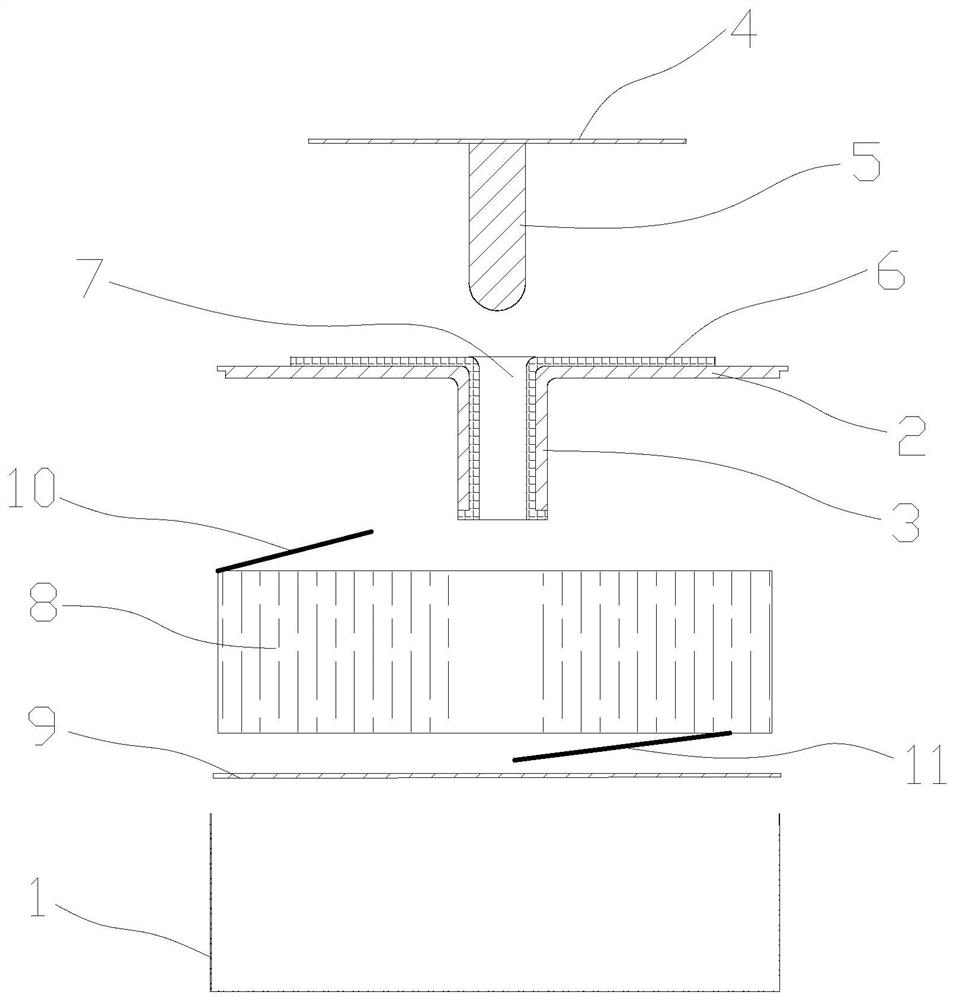

[0035] Example 1: Reference figure 1 , 2, a button battery explosion-proof sealing structure, the structure is mainly used for the shell of the battery, especially the button battery, the technical solution proposed in this embodiment aims to avoid damage to electronic equipment or While causing adverse effects on the users of electronic equipment, it is necessary to further improve the structural stability of the cover and the battery as a whole due to the explosion-proof structure. The structure includes a housing 1 having a bottom surface and a side wall extending around the edge of the bottom surface. In this embodiment, the housing 1 is a cylindrical structure with an upper end opening; The plate 2 is connected with the shell 1 to form a hollow cavity. The shell 1 and the cover plate 2 are made of stainless steel. The shell 1 and the cover plate 2 made of stainless steel can prevent the battery from rusting and prolong the service life of the battery; It also includes a...

Embodiment 2

[0040] Example 2: Reference figure 1 and figure 2 , a button battery in this embodiment, including the explosion-proof sealing structure of the button battery described in Embodiment 1; it also includes an electrode assembly 8 and an electrolyte located inside the cavity, and one side of the electrode assembly 8 is connected to the shell through a positive electrode conductor 10 On the body 1 or the cover plate 2, the other side of the electrode assembly 8 is connected to the explosion-proof column 5 through the negative electrode conductor 11, and an insulating pad 9 is provided between the electrode assembly 8 and the bottom surface of the casing 1, and the insulating pad 9 is in the shape of a disc. The surface area of the insulating pad 9 may be equal to or smaller than that of the bottom surface of the housing 1 , and the material of the insulating pad 9 includes one or more of polypropylene, propylene-ethylene copolymer, polyether ether ketone, and polyvinylidene fluo...

Embodiment 3

[0043] Embodiment 3: a kind of packing method of button cell, this method is used for packing the button cell described in embodiment 2, and it comprises the following steps:

[0044] S1, coating the periphery and the inner wall of the explosion-proof hole 7 with a sealing insulating layer 6;

[0045] Specifically, the periphery of the explosion-proof hole 7 on the cover plate 2 and the inner wall of the explosion-proof hole 7 are coated with a sealing insulating layer 6, and the area of the sealing insulating layer 6 is not less than the area of the electrode sheet 4 to ensure insulation between the electrode sheet 4 and the cover plate 2. connect. The edge of the explosion-proof hole 7 integrally extends along the direction of the cavity to form a hollow clamping sleeve 3 , and the inner wall of the clamping sleeve 3 is also coated with a sealing insulating layer 6 .

[0046] S2. Attach the electrode piece 4 to the sealing insulating layer 6 on one side of the cover pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com