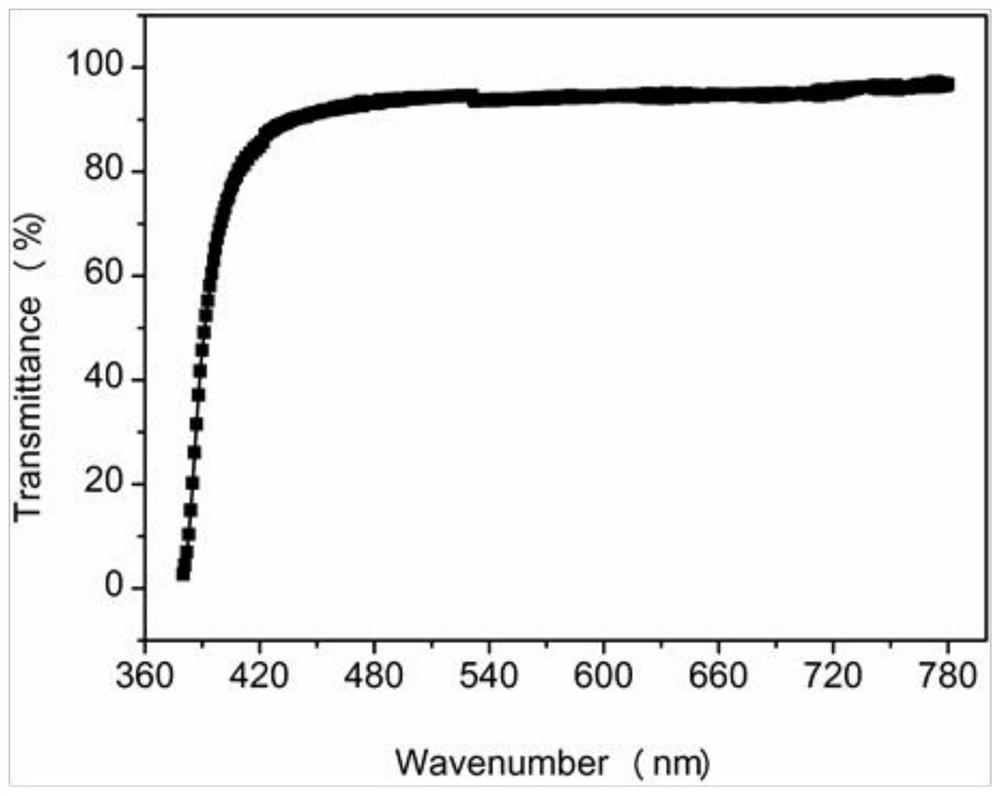

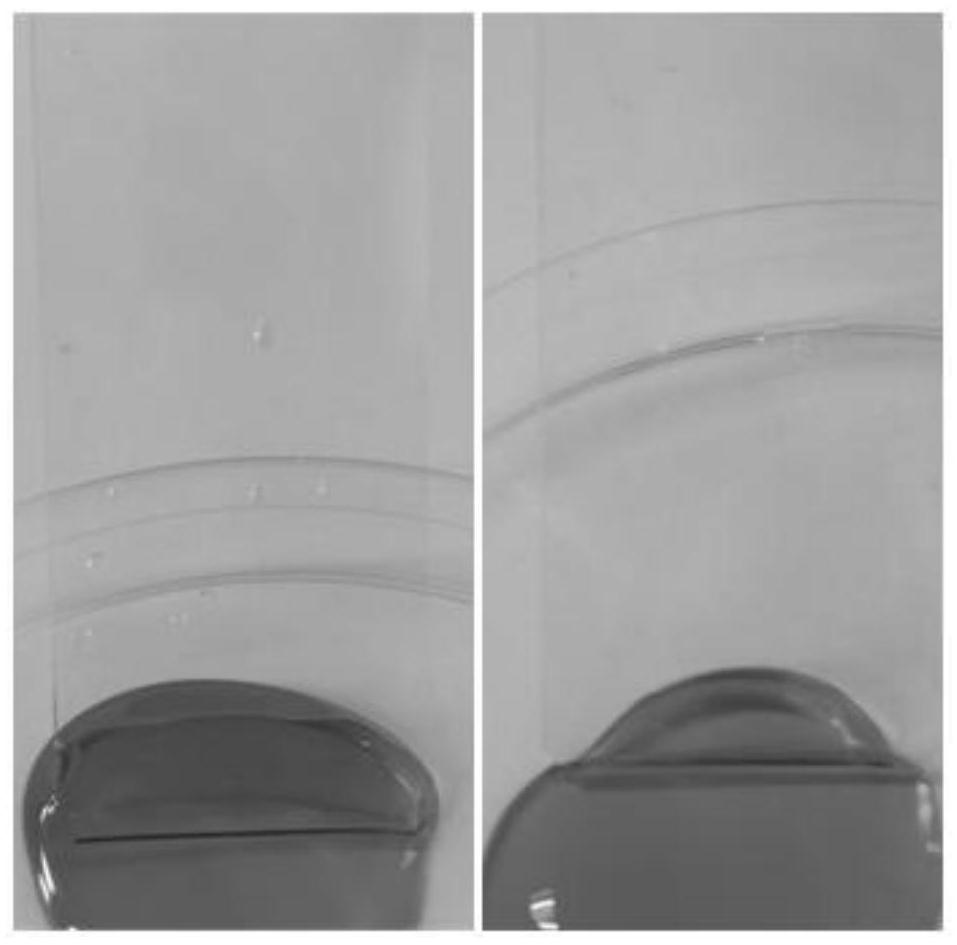

Transparent hydrophobic photocureable coating and preparation method thereof

A light-curing coating and light-curing technology, applied in coatings, polyether coatings, etc., can solve the problems of weak adhesion of substrate materials, loss of surface hydrophobicity, high light transmittance, etc., and achieve low surface tension, high Application and industrial value, the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method and application of a transparent hydrophobic light-cured coating, comprising the following steps:

[0030] (1) Add pentaerythritol oleate (monosubstituted), 3-mercaptopropyltriethoxysilane and photoinitiator 1173 into the beaker at a mass ratio of 5:4:1, measure in 10 grams, and stir evenly with magnetic force. Obtain photocurable coating.

[0031] (2) Spin-coat the photocurable coating prepared in step (1) onto the glass surface, and then irradiate the substrate under a UV light source for 5 min at a light intensity of 250 mW cm -2 , a transparent hydrophobic photocurable coating can be obtained.

Embodiment 2

[0033] A preparation method and application of a transparent hydrophobic light-cured coating, comprising the following steps:

[0034] (1) Add glycerol oleate (monosubstituted), pentaerythritol tetra-3-mercaptopropionate and photoinitiator 651 into ethanol at a mass ratio of 5:3:2, measure with a solid content of 10%, and then add it to a beaker, Stir evenly with magnetic force to obtain photocurable coating.

[0035] (2) Spin-coat the light-curing coating prepared in step (1) onto the glass surface. After the solvent evaporates at room temperature, place the substrate under a UV light source for 1 min, and the light intensity is 500mW cm -2 , a transparent hydrophobic photocurable coating can be obtained.

Embodiment 3

[0037] A preparation method and application of a transparent hydrophobic light-cured coating, comprising the following steps:

[0038] (1) Add disubstituted polyethylene glycol oleate, 2-mercaptoethyltriethoxysilane and photoinitiator 184 into acetone at a mass ratio of 5:4:3, measure with a solid content of 10%, and then add In the beaker, magnetically stir evenly to obtain the light-cured coating.

[0039] (2) Spin-coat the light-curing coating prepared in step (1) onto the surface of PMMA. After the solvent evaporates at room temperature, place the substrate under an ultraviolet light source for 2 min, and the light intensity is 300 mW cm -2 , a transparent hydrophobic photocurable coating can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com