Rapid tunneling method for coal mine bottom drainage roadway

It is a fast technology for bottom pumping roadway, which is applied in mining equipment, earthwork drilling, shaft lining, etc. It can solve the problems that the track line cannot be extended to the working face, the driving efficiency of bottom pumping roadway is low, and the connection imbalance of mine excavation is solved. The effect of long-distance material transportation is difficult, the empty gang time is reduced, and the tunneling efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

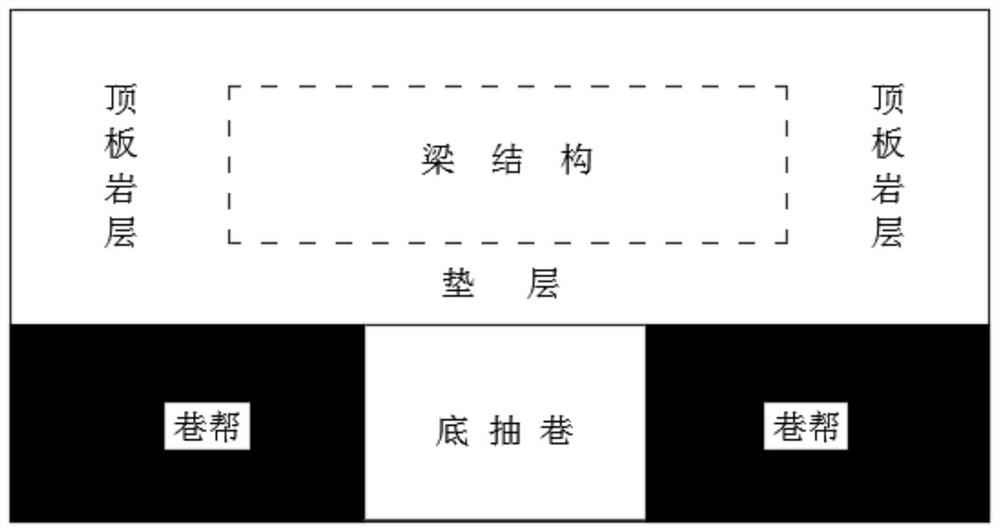

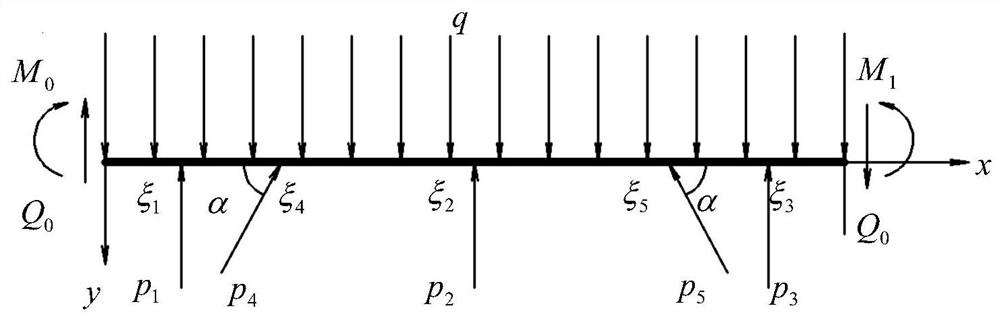

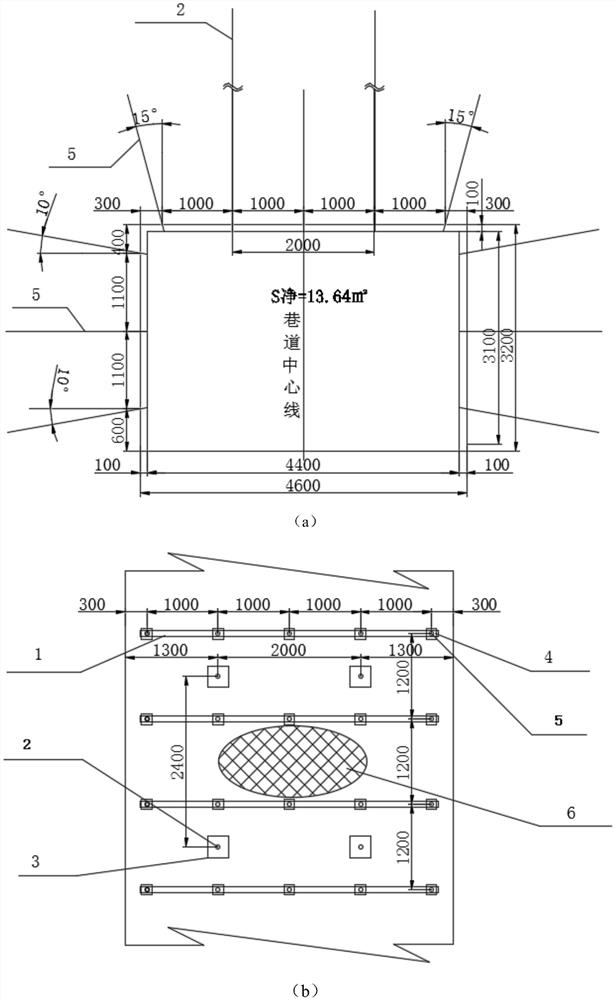

[0044] This embodiment provides a rapid excavation method for the bottom pumping roadway in a coal mine, including theoretical analysis, experimental testing, numerical calculation and engineering analogy, to obtain the roof of the bottom pumping roadway in the bottom mine, the surrounding rock mass, and the supporting structure. The relationship between the distance between the roof and the influence characteristics of the distance of the roof on the stress distribution and plastic failure range of the surrounding rock of the roadway reveals the evolution law of the stability of the roof in the roof area; The new rapid excavation technology of bottom pumping roadway with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com