Light-emitting diode with latticed metal film and preparation method thereof

A technology of light-emitting diodes and metal films, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of current congestion and low light utilization rate, and achieve the effects of increasing conductivity, improving uniformity, and reducing surface roughness and scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

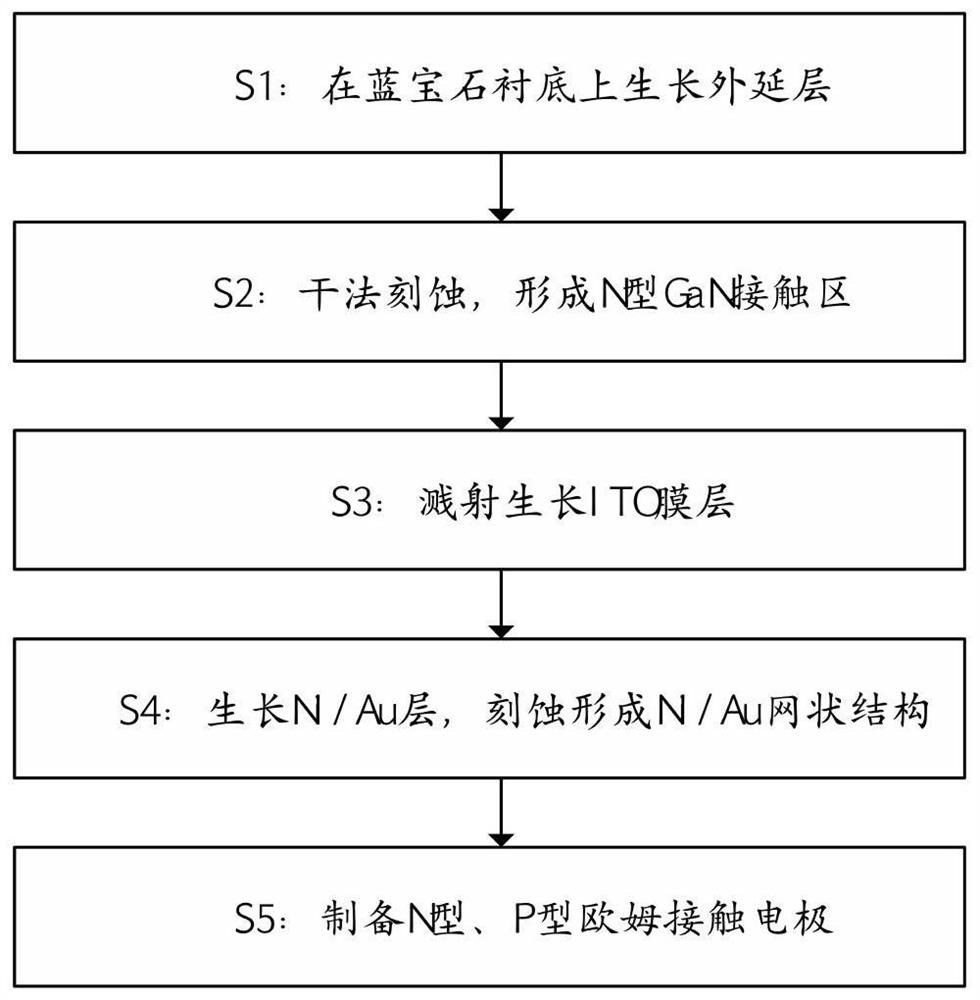

[0030] Embodiment 1: This embodiment provides a light-emitting diode with a grid-shaped metal film and a preparation method thereof, and the specific steps include:

[0031] S1 grow epitaxial layer on sapphire substrate

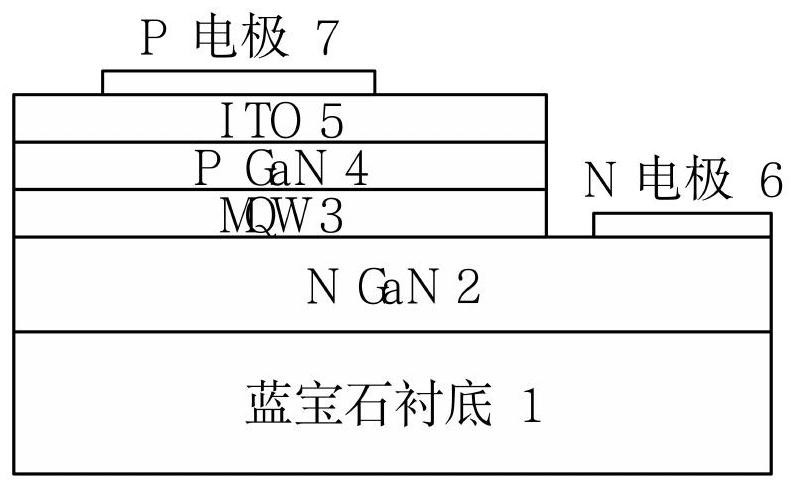

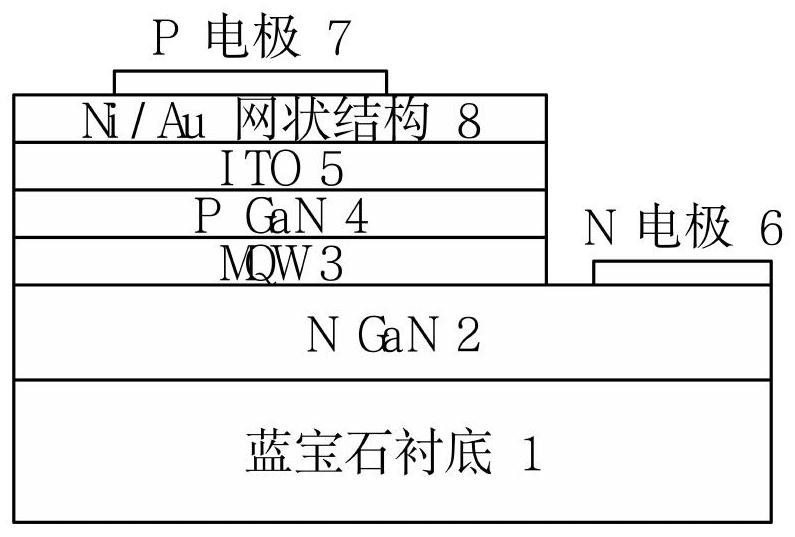

[0032] Such as Figure 4 As shown, an N-type GaN layer 2 and a P-type GaN layer 4 are epitaxially grown sequentially using MOCVD equipment on a sapphire substrate. Quantum well layer 3 is formed between N-type GaN layer 2 and P-type GaN layer 4 .

[0033] S2 dry etching to form N-type GaN contact area

[0034] Such as Figure 5 As shown, after applying glue and developing the photolithographic hard film, use the photoresist as a mask to etch P-type GaN, and the etching gas is Cl 2 / Ar / BCl 3 , so that the surface of the N-type GaN is exposed.

[0035] S3 sputtering growth of ITO film layer

[0036] Such as Figure 6 As shown, using the DC magnetron sputtering method, using the linear continuous coating machine to sputter and grow the ITO film layer, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com