Efficient flotation method for copper regeneration and recovery smelting slag

A smelting slag and high-efficiency technology, which is applied in the field of high-efficiency flotation of smelting slag for copper regeneration and recovery, can solve the problems of difficult separation, complicated operation and large floor space, and achieves the effects of many bubbles, cumbersome operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

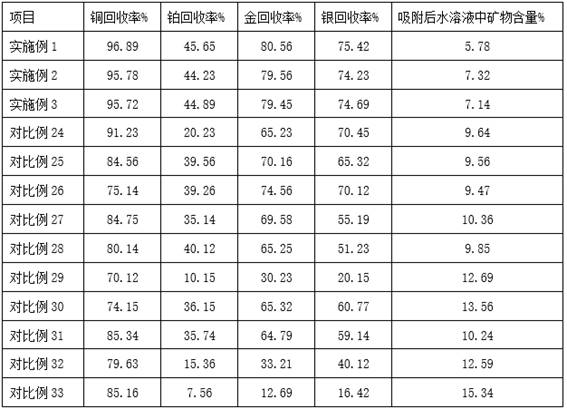

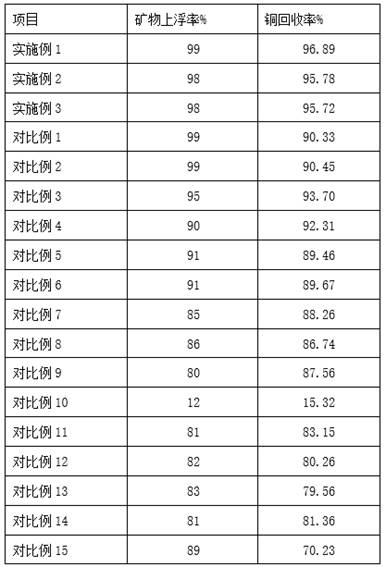

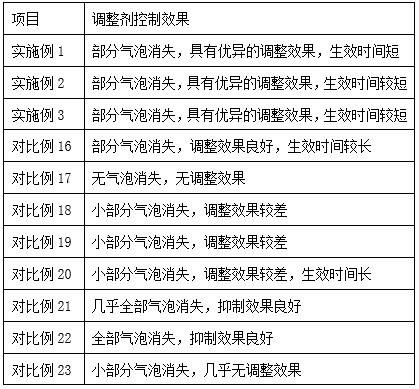

Examples

Embodiment 1

[0047] A high-efficiency flotation method for copper regeneration and recovery of smelting slag, the specific flotation process is as follows:

[0048] 1) Pretreat the slag, crush the slag through a jaw crusher, and then put it into a ball mill for ball milling, so that the particle size of the crushed particles can pass through a 400-mesh sieve;

[0049] 2) Put the above-prepared powder into the pretreatment tank, add Thiobacillus thiaphulum into the tank, add buffer and water, adjust the pH to 6.0, submerge the powder in the liquid, heat up while stirring, at 2°C / min The temperature is raised to 23°C for 4 days, among which minerals: Thiobacillus thiaphus = 1t: 20kg;

[0050] 3) Filter the above mixture to remove the mud, transfer the remaining substances to the flotation collection tank, add the modified collector for flotation collection, and adjust the pH value to 5.0 at the same time, and the solution temperature is 30°C. The mass ratio of the collector is 1t: 2kg;

[...

Embodiment 2

[0079] A high-efficiency flotation method for copper regeneration and recovery of smelting slag, the specific flotation process is as follows:

[0080] 1) Pretreat the slag, crush the slag through a jaw crusher, and then put it into a ball mill for ball milling, so that the particle size of the crushed particles can pass through a 400-mesh sieve;

[0081] 2) Put the above-prepared powder into the pretreatment tank, add Thiobacillus thiaphulum into the tank, add buffer and water, adjust the pH to 5.5, submerge the powder in the liquid, heat up while stirring, at 1°C / min The temperature is raised to 25°C for 3 days, among which minerals: Thiobacillus thiaphulens = 1t: 20kg;

[0082] 3) Filter the above mixture to remove the mud, transfer the remaining substances to the flotation collection tank, add modified collectors for flotation collection, and adjust the pH value to 5.5 at the same time, the solution temperature is at 35 ° C, the mixture and the modified The mass ratio of ...

Embodiment 3

[0111] A high-efficiency flotation method for copper regeneration and recovery of smelting slag, the specific flotation process is as follows:

[0112] 1) Pretreat the slag, crush the slag through a jaw crusher, and then put it into a ball mill for ball milling, so that the particle size of the crushed particles can pass through a 400-mesh sieve;

[0113] 2) Put the above-prepared powder into the pretreatment tank, add Thiobacillus thiaphulum into the tank, add buffer and water, adjust the pH to 6.5, submerge the powder in the liquid, heat up while stirring, at 3°C / min The temperature is raised to 20°C for 3 days, among which minerals: Thiobacillus thiaphus = 1t: 20kg;

[0114] 3) Filter the above mixture to remove the mud, transfer the remaining substances to the flotation collection tank, add the modified collector for flotation collection, and adjust the pH value to 4.5 at the same time, the solution temperature is at 25°C, the mixture and the modified The mass ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com