Display panel and its test terminals

A technology for testing terminals and display panels, applied to static indicators, identification devices, instruments, etc., can solve problems such as corrosion, test wiring corrosion, and scrapped display panels, and achieve strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

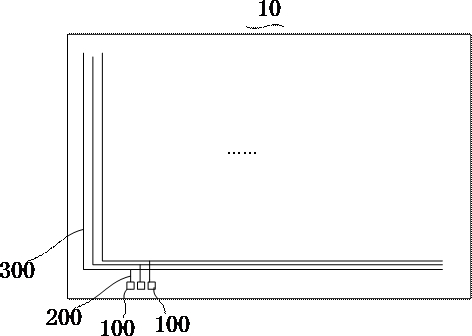

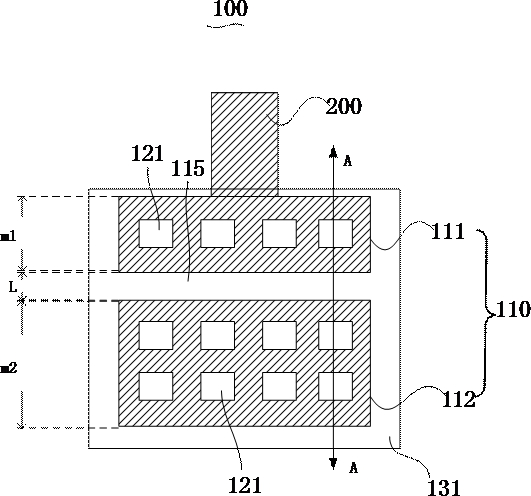

[0034] Such as figure 1 As shown, as the first embodiment of the present application, a schematic diagram of a display panel 10 is disclosed, including a plurality of test lines 200 and a plurality of test terminals 100, a plurality of test terminals 100 and a plurality of test lines The lines 200 are connected in one-to-one correspondence. The test lines 200 are connected to the driving lines 300 inside the display panel 10. The driving lines 300 may include data lines, scanning lines, gate driving lines, source driving lines, and clock signals. line etc. It should be noted that the main improvement of this application lies in the structure of the test terminal 100, and the test terminal 100 is not limited to the connection of the test wiring 200, and the corresponding wiring inside the display panel 10 that needs to be connected to the test terminal 100 is applicable, which belongs to this application scope of protection. The test terminal 100 will be used for specific des...

Embodiment 2

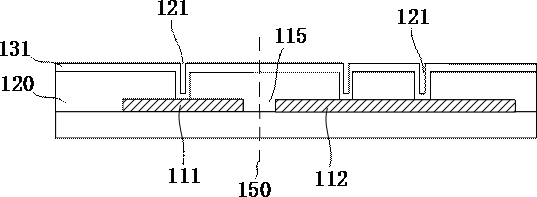

[0058] Such as Figure 9 As mentioned above, as the second embodiment of the present application, the difference from the previous embodiment is that the position of the connecting electrode layer 131 is different, Figure 9 shows a schematic diagram of the corrosion of the test wiring 200 and the test terminal 100, Figure 10 show Figure 9 A schematic cross-sectional view along the C-C cutting line 150.

[0059] The connecting electrode layer 131 is disposed under the first metal pad 111 and the second metal pad 112 corresponding to the discontinuity portion 115; the corrosion-resistant conductive material includes indium tin oxide material, the The test connection wires are made of indium tin oxide material. The test terminal 100 also includes an insulating layer 120 and a transparent conductive layer 130, the insulating layer 120 is disposed on the metal layer 110, and between the first metal pad 111 and the second metal pad 112 Separated by the insulating layer 120, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com