Chemical coating material with resistance to geothermal water corrosion and preparation method of chemical coating material

A technology of chemical plating and geothermal water, which is applied in the field of chemical plating materials and its preparation, can solve problems such as corrosion and scaling easily, and achieve the effects of maintaining stability, promoting adsorption, and inhibiting contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

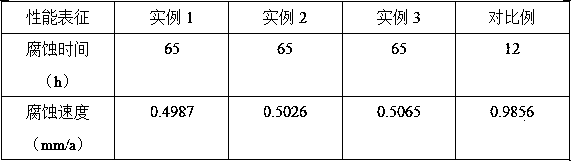

Examples

Embodiment Construction

[0018] Take 20~30g nickel sulfate, 0.2~0.5g copper sulfate, 20~30g sodium dihydrogen phosphate, 8~12g sodium acetate, 10~20g borax, 0.010~0.015g sodium citrate, 0.02~0.03g oxalic acid, add 1000~ 1200mL deionized water, stirred at 300-400r / min for 20-30min to obtain a mixed solution, added 1-2g nanometer zirconia, 0.05-0.08g surfactant to the mixed solution, and 350W ultrasonic wave at 40-50℃ Ultrasonic dispersion for 20 to 30 minutes, and then use 50% ammonia water to adjust the pH to 4 to 5 to obtain a dispersion, add 10 to 20 g of organic additives to the mixture, and stir at 300 to 400 r / min for 20 to 30 minutes to obtain a Electroless coating materials corroded by geothermal water.

[0019] Take 20g of nickel sulfate, 0.2g of copper sulfate, 20g of sodium dihydrogen phosphate, 8g of sodium acetate, 10g of borax, 0.010g of sodium citrate, and 0.02g of oxalic acid, add them to 1000mL of deionized water, and stir at 300r / min for 20min to obtain a mixture. Add 1g of nanometer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com