Grinding machine and permanent magnet machining process applying same

A grinding machine and table body technology, applied in stone processing tools, grinding machine parts, grinding machines, etc., can solve problems such as easy stabbing of transfer personnel, safety accidents, etc., to improve cutting efficiency and cutting accuracy, save resources, The effect of reducing the probability of security incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

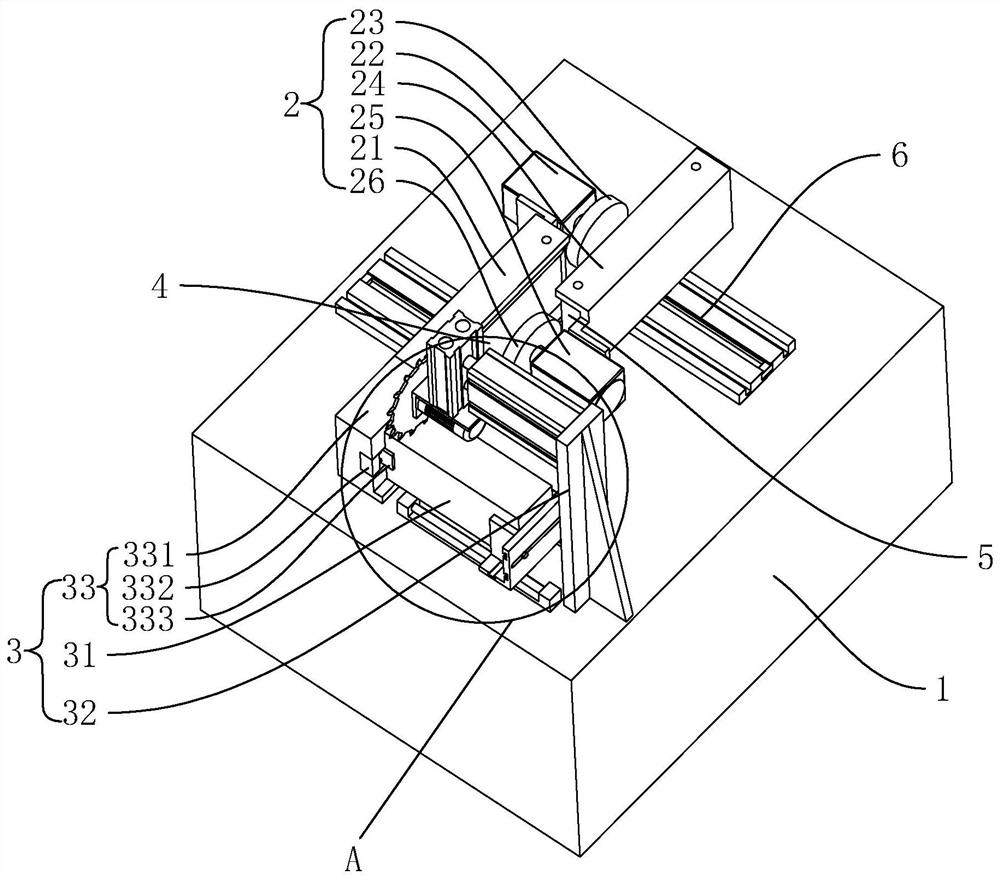

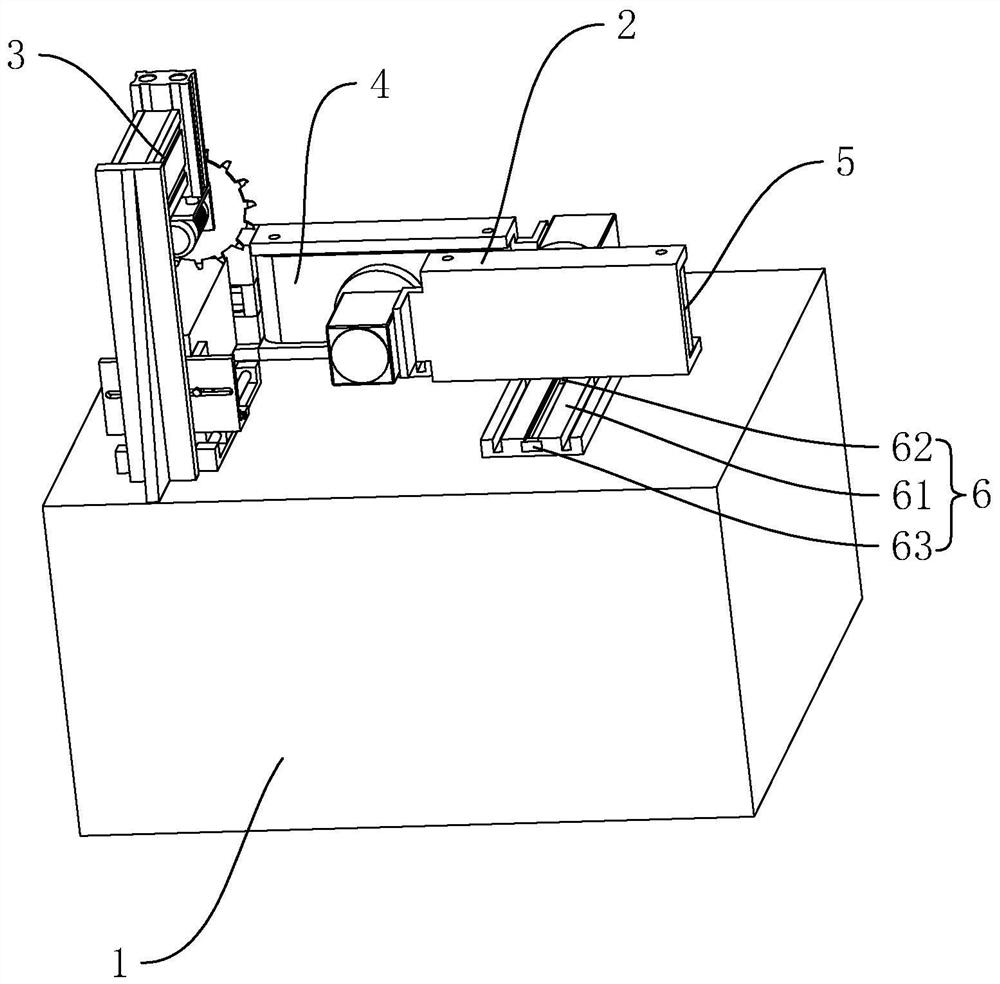

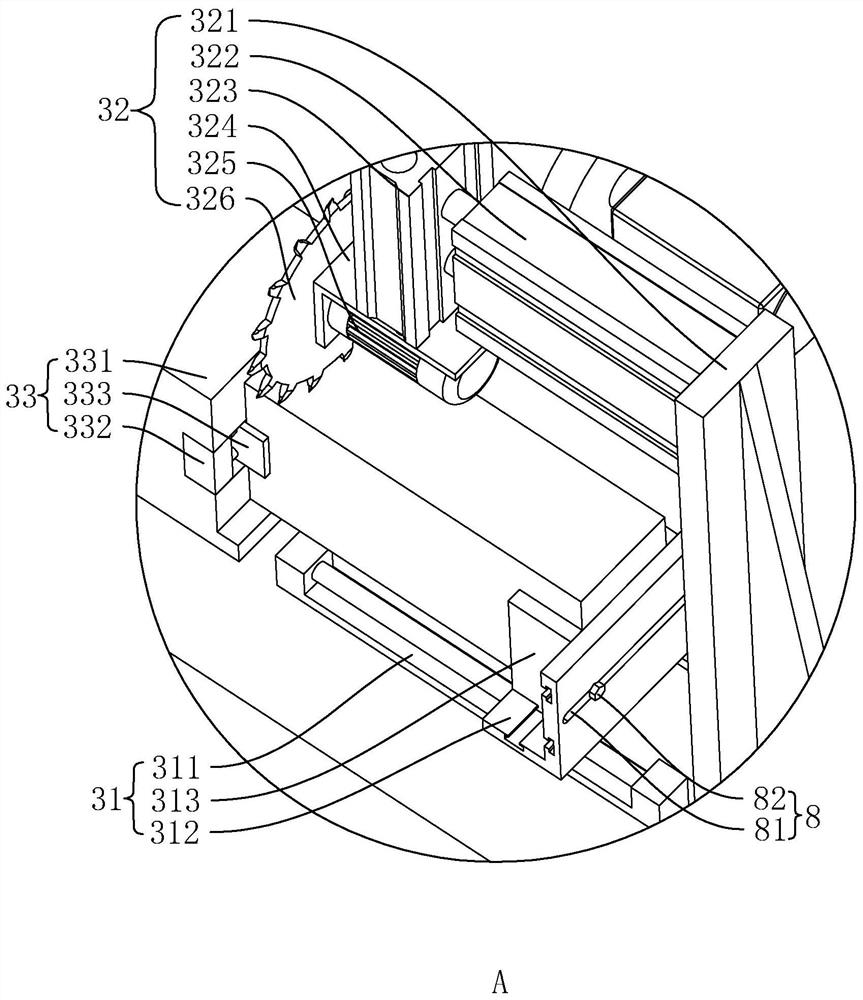

[0040] The following is attached Figure 1-3 The application is described in further detail.

[0041] The embodiment of the present application discloses a grinding machine, referring to figure 1 , including a cuboid table body 1, a grinding device 2 is installed on the table body 1, and materials are fed from one end of the length direction of the table body 1, and a slicing device 3 is provided at the feeding end of the grinding device 2, and the slicing device 3 includes a The clamping assembly 31 on the body 1, the cutting assembly 32 installed on the table body 1, and the conveying assembly 33 installed on the grinding device 2, the conveying assembly 33 includes an abutment table fixed at the feeding end of the grinding device 2 331, the pusher 332 installed on the abutting platform 331 and the push plate 333 installed on the pusher 332, the pusher 332 is a rodless cylinder, the pusher 333 is installed on the slider of the rodless cylinder, and the pusher 332 drives Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com