Preparation method and application of oriented conductive low-temperature-resistant hydrogel

A conductive hydrogel, hydrogel technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, etc., can solve the problem of weak mechanical properties and electrical conductivity of hydrogels, affecting durability and practical applications, limiting applications, etc. problems, to achieve the effect of improving mechanical strength and application prospects, high sensitivity and stability, and easy gelation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) First add 1g of LiF to 20mL of hydrochloric acid and stir for 5 minutes. 1g Ti 3 AlC 2 The above solution was added slowly and stirred at 35°C for 26 hours to obtain a black suspension. The acidic suspension was then washed with deionized water and centrifuged at 4500 rpm for 5 minutes until the pH of the supernatant reached 6.0. Then collect the sediment, add deionized water to the sediment, pass Ar into the dispersion for 10 minutes and sonicate for 1 hour, and add ice packs to keep the temperature low. Finally, centrifuge at 5000 rpm for 10 minutes and freeze-dry at -50°C for 3 days to obtain fluffy black powder A of MXene nanosheets.

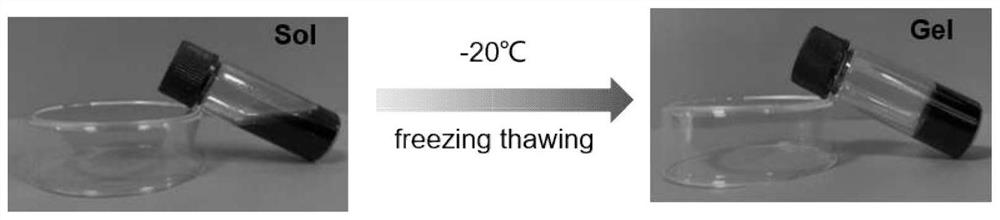

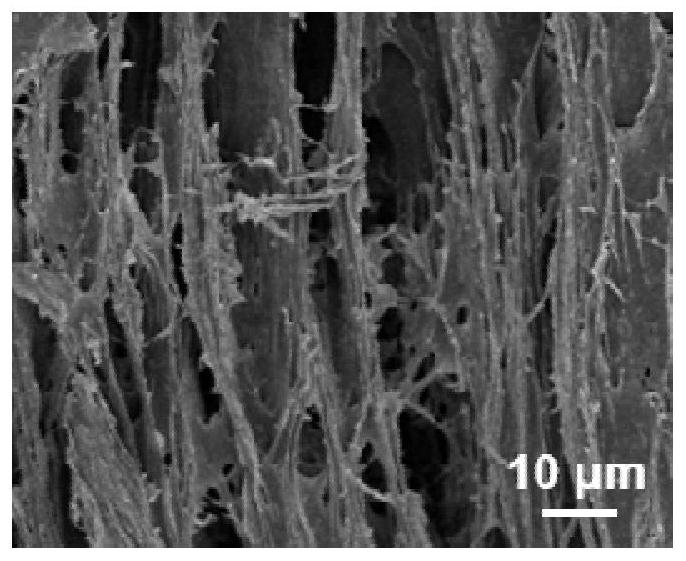

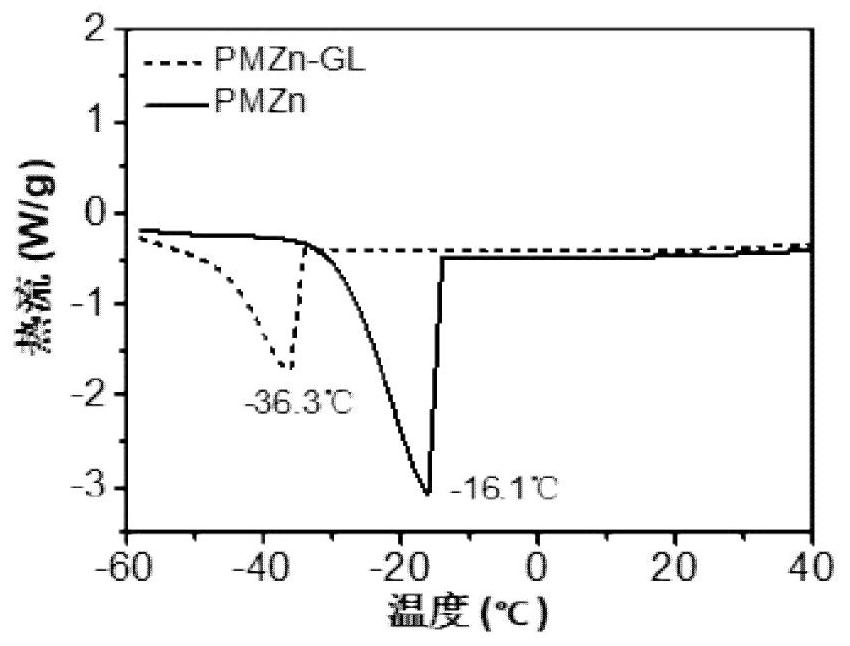

[0019] 2) First, 6.25g of PVA powder was added to 42.75g of deionized water and vigorously stirred at 90°C for 6 hours to obtain a solution of 12.5wt% PVA. The black solid powder A prepared in the first step was added to deionized water to form a concentrated solution of 15mg / ml, and then ultrasonically passed through a cell pu...

Embodiment 2

[0022] 1) First add 1g of LiF to 20mL of hydrochloric acid and stir for 5 minutes. 1g Ti 3 AlC 2 The above solution was slowly added and stirred at 40 °C for 24 hours to obtain a black suspension. The acidic suspension was then washed with deionized water and centrifuged at 3500 rpm for 8 minutes until the pH of the supernatant reached 6.0. Then collect the sediment, add deionized water to the sediment, pass Ar into the dispersion for 20 minutes and sonicate for 1.5 hours, and add ice packs to keep the temperature low. Finally, centrifuge at 4500 rpm for 10 minutes and freeze-dry at -50°C for 3 days to obtain fluffy black powder A of MXene nanosheets.

[0023] 2) First, 5 g of PVA powder was added to 45 g of deionized water and vigorously stirred at 90° C. for 6 hours to obtain a 10 wt % PVA solution. The black solid powder A prepared in the first step was added to deionized water to form a concentrated solution of 15mg / ml, and then ultrasonically passed through a cell pul...

Embodiment 3

[0026] 1) First add 1g of LiF to 20mL of hydrochloric acid and stir for 5 minutes. 1g Ti 3 AlC 2 The above solution was added slowly and stirred at 35°C for 26 hours to obtain a black suspension. The acidic suspension was then washed with deionized water and centrifuged at 4500 rpm for 5 minutes until the pH of the supernatant reached 6.0. Then collect the sediment, add deionized water to the sediment, pass Ar into the dispersion for 10 minutes and sonicate for 1 hour, and add ice packs to keep the temperature low. Finally, centrifuge at 5000 rpm for 10 minutes and freeze-dry at -50°C for 3 days to obtain fluffy black powder A of MXene nanosheets.

[0027] 2) First, 6.25g of PVA powder was added to 42.75g of deionized water and vigorously stirred at 90°C for 6 hours to obtain a solution of 12.5wt% PVA. The black solid powder A prepared in the first step was added to deionized water to form a concentrated solution of 15mg / ml, and then ultrasonically passed through a cell pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com