Wide-working-condition efficient water making machine

A water-making machine, high-efficiency technology, applied in water supply equipment, drinking water equipment, buildings, etc., can solve the problems of low water production efficiency and unsustainable water production, and achieve the effect of improving efficiency, expanding the scope of working conditions, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

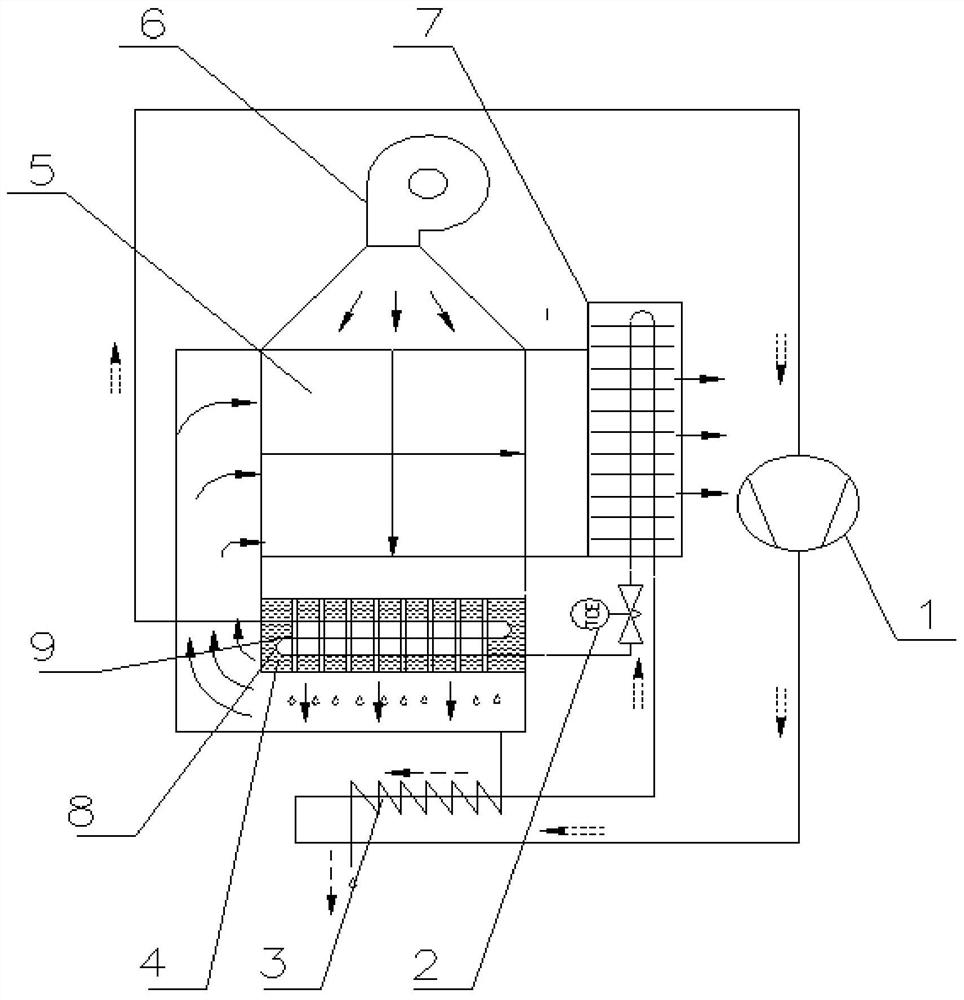

[0022] Such as figure 1 Shown is the structural principle diagram of the present invention, figure 1 middle is the refrigerant flow direction, is the direction of air flow, for water flow. The present invention is a high-efficiency water generator in wide working conditions, including a compressor 1, a throttling element 2, a condensed water recovery pipe 3, a high-efficiency condenser, a pre-cooling heat exchanger 5, a fan 6, a condenser 7, and a connecting air duct 10, of which:

[0023] The pre-cooling heat exchanger 5 is a plate-type sensible heat recovery device. There are two mutually independent passages in the pre-cooling heat exchanger 5. The two passages are perpendicular to each other. One of the passages is a vertical passage and the other is a horizontal passage. The air inlet at the top of the fan 6 leads to the external environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com