Waste lithium cobalt oxide battery treatment methodand product thereof

A technology of waste lithium cobalt oxide and treatment method, which is applied in the direction of lithium storage battery, battery electrode, battery recycling, etc., can solve the problems of high acid consumption and more secondary waste liquid, etc. The effect of cross-generation upgrade to prepare ternary power lithium battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

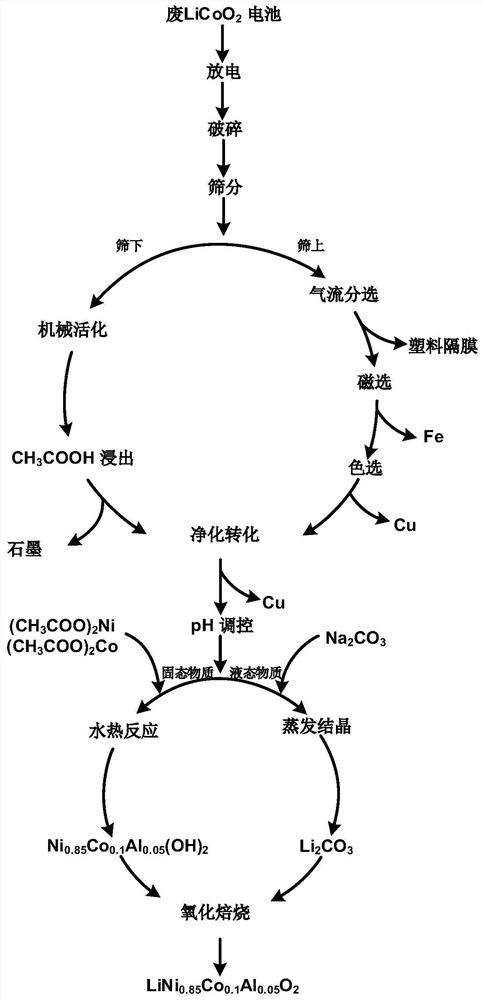

[0113] like figure 1 As shown, a method for in-situ upgrading of waste lithium cobaltate batteries to nickel-cobalt-aluminum ternary lithium batteries comprises the following steps:

[0114] (1) In order to ensure the safety of the experimental process, 100 waste lithium cobaltate mobile phone lithium batteries of about 2.5kg were fully discharged in 5% NaCl-KCl salt solution for 48 hours, and then dried in the fume hood for 48 hours;

[0115] (2) The massive waste lithium battery after discharge has been coarsely crushed by a shear crusher and finely crushed by a universal crusher to obtain fully dissociated crushed products;

[0116] (3) The crushed product falls into the circular hole vibrating screen for sieving and separation;

[0117] (4) The material on the circular vibrating screen is first sorted by pulsating air flow, and the light product diaphragm and plastic products are blown out from the upper vent and collected as plastic products, and the metal flakes or meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com