Spraying rotating stirring device for preparing dialysate

A technology of rotating stirring and dialysate, which is applied in the field of medical equipment, can solve the problems of high noise, high power of motor or water pump, and easy loss, etc., and achieve the effect of low noise and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

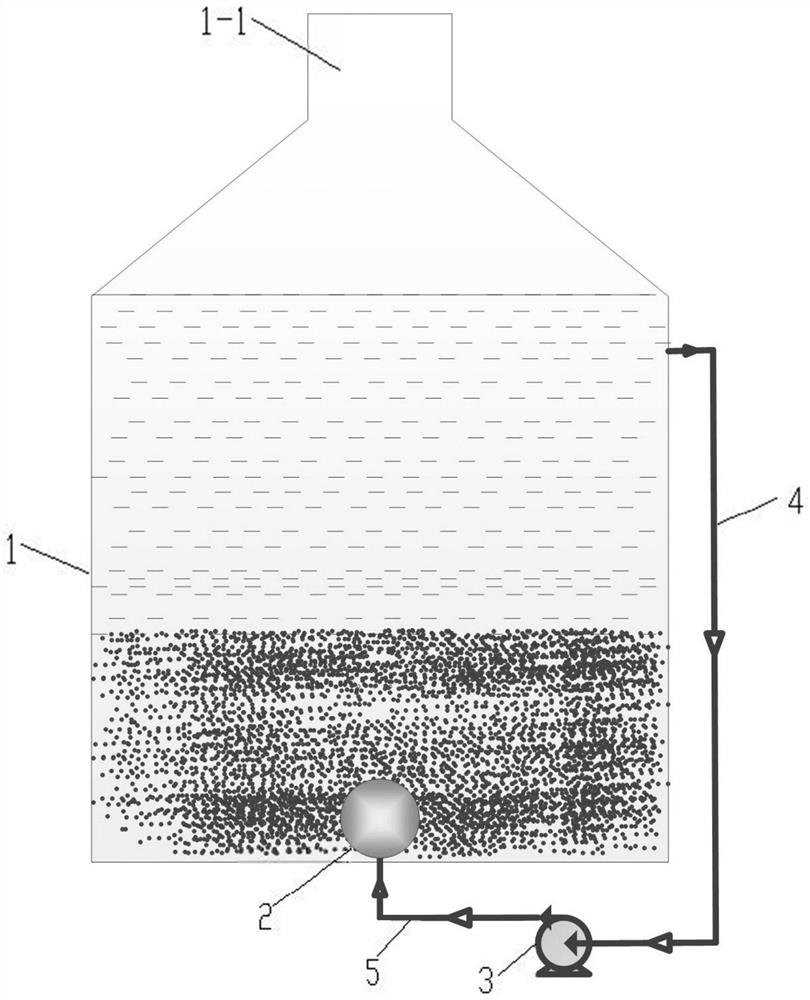

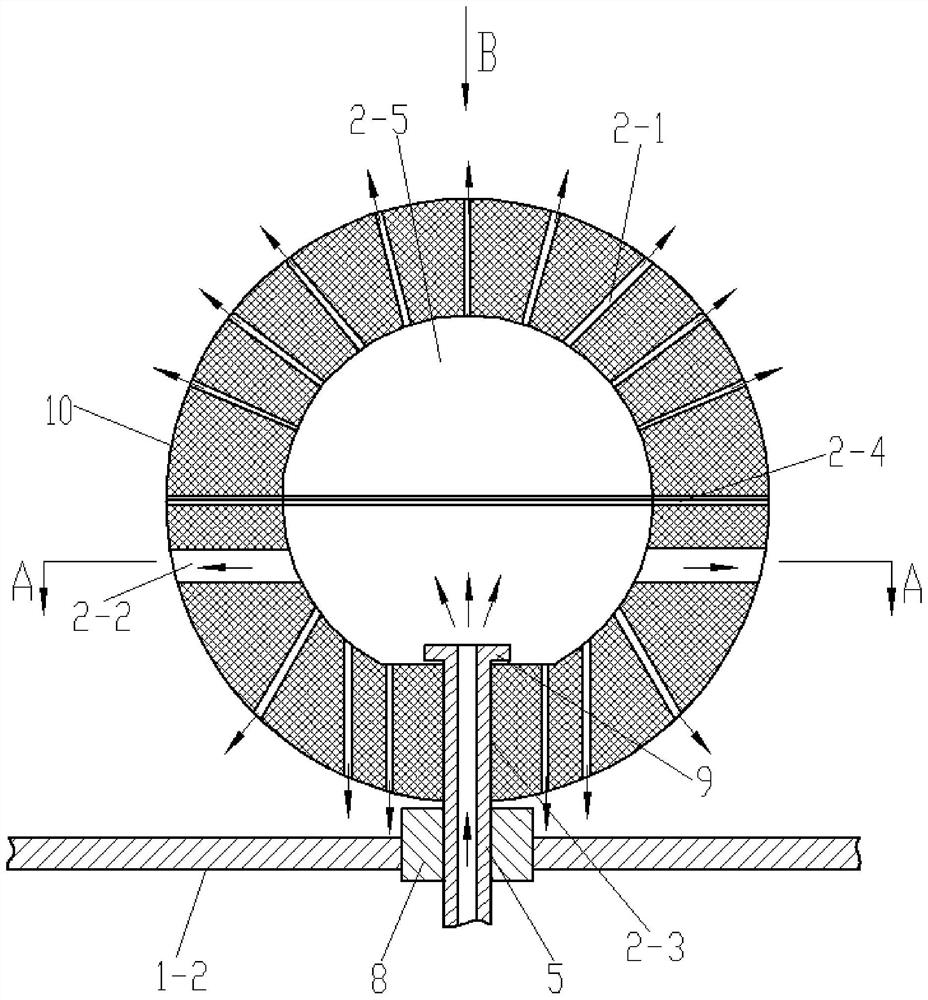

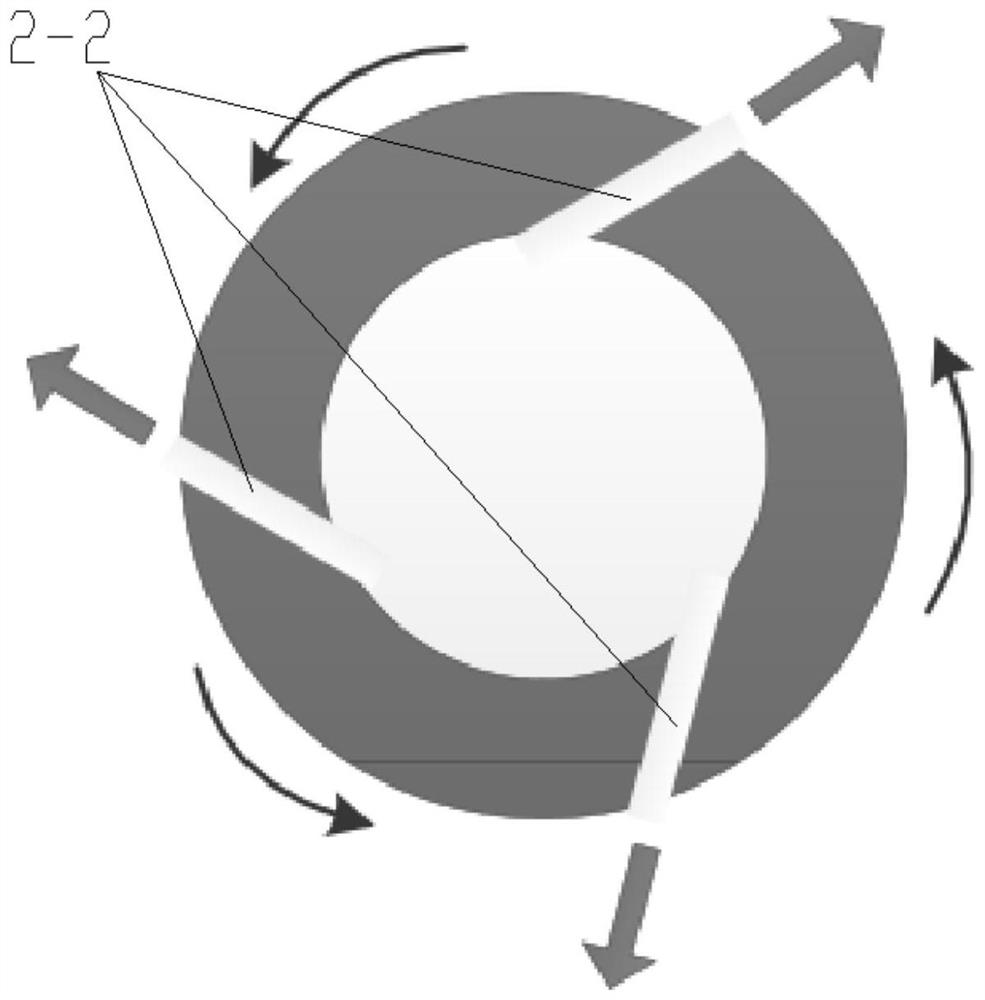

[0039] Spray rotary stirring device for dialysate preparation, such as figure 1 and 2 As shown, a preparation container 1 is included, and the upper end of the preparation container 1 is provided with a filling port 1-1 for putting dialysis powder and injecting reverse osmosis water. It also includes a spraying rotary stirring nozzle 2 and a micro circulating water pump 3, the inlet of the micro circulating water pump 3 is connected to the circulation pipeline I4, the outlet of the micro circulation water pump 3 is connected to one end of the circulation pipeline II5, and the other end of the circulation pipeline II5 is sealed through The center of the container bottom wall 1-2 of the preparation container 1 extends into the bottom of the inner cavity of the preparation container 1, and the end of the circulation pipeline II 5 extending into the preparation container 1 is rotatably connected with a jet rotary stirring nozzle 2 . The inner cavity of the spraying rotary stirrin...

Embodiment 2

[0043] The shape of the jet rotating stirring nozzle 2 is a spherical structure 10 (such as figure 2 shown) or hemispherical structure 11 (such as Figure 5 shown) or cylindrical structure 12 (such as Figure 6 shown); this structure can reduce the rotational resistance of the jet rotary stirring nozzle 2 under the reaction force.

Embodiment 3

[0045] The outer wall of the jet rotary stirring nozzle 2 is a thick-walled structure or a thin-walled structure, such as figure 2 and 5 Shown is a schematic diagram of a thick-walled material, such as Figure 9 and 11 Shown is a schematic diagram of thin-walled materials, and a wide range of materials can be manufactured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com