Method for preparing aviation oil precursor by catalytic depolymerization of alkali lignin in ethanol-water solvent through cooperation of Pd/C catalyst and alkali catalyst

A technology of alkali lignin and alkali catalyst, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of product complexity and difficult to achieve efficient depolymerization of alkali lignin Solve the problems of monocyclic aromatic compounds, intensified repolymerization, and low yield of monocyclic aromatic compounds, etc., to achieve the effect of strengthening bond breaking ability, promoting depolymerization degree, and improving bond breaking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

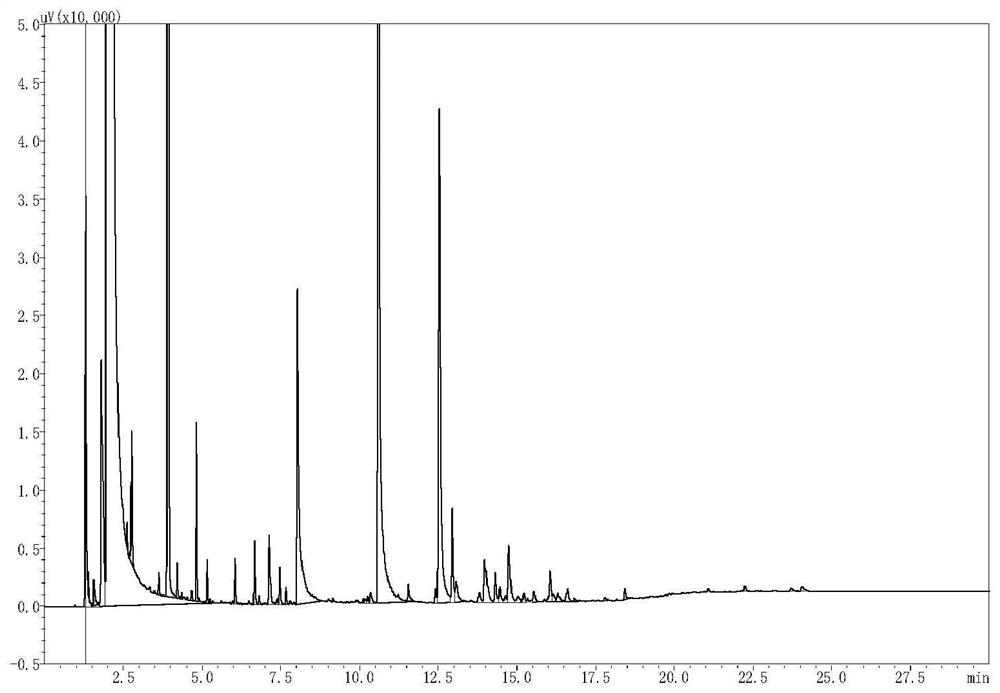

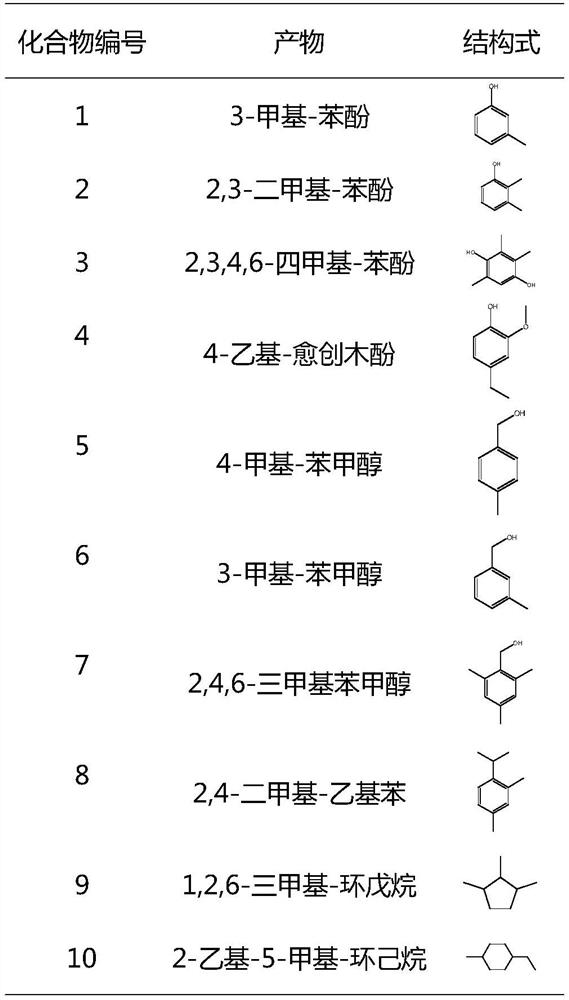

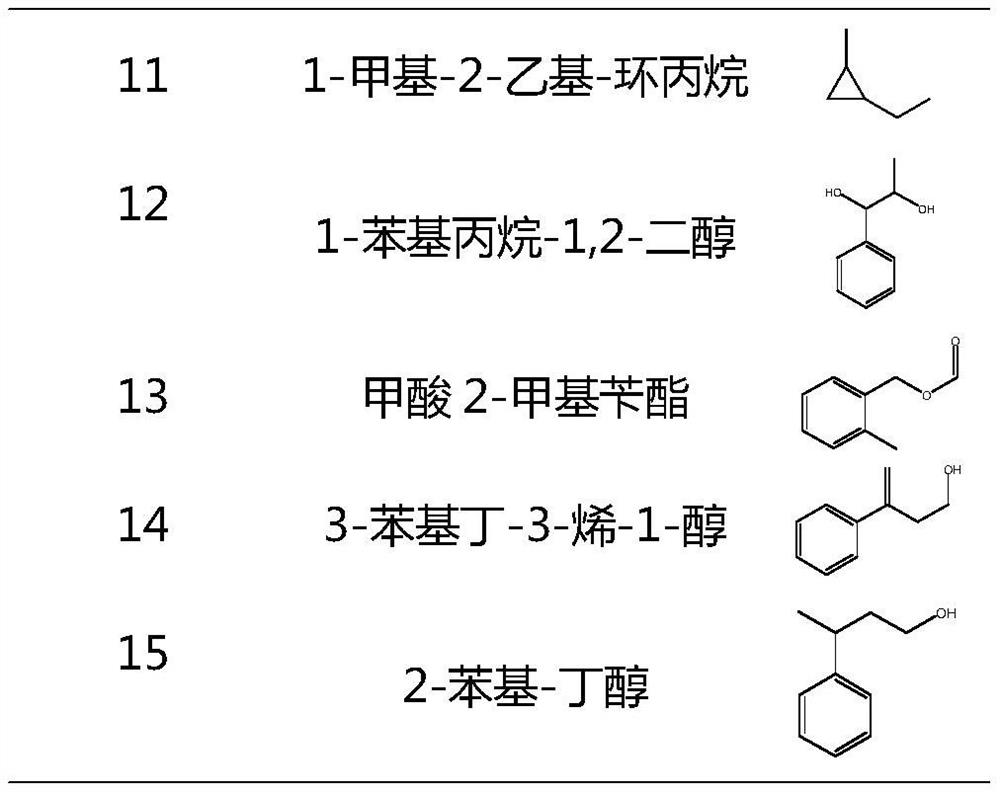

[0027] Depolymerization reaction of alkali lignin: a 100mL autoclave reactor was selected as the reaction device for depolymerization of alkali lignin to prepare monocyclic aromatic compounds. Before the reaction, 0.5 g of alkali lignin, Pd / C catalyst and 40 mL of ethanol-water two-phase solvent with a volume ratio of 3:2 were charged into the reactor. Seal the reactor to H 2 The reactor was purged three times and pressurized to 2MPa to wait for the reaction to start. After the reaction started, the material was mechanically stirred, the stirring speed was set to 400r / min, and the temperature rising program was set (from room temperature (about 30°C) to the target temperature (260°C), and the heating rate was 3°C / min), when After the reaction kettle rises to the target temperature, start timing according to the time required for the reaction until the end of the reaction time. After the reaction, turn off the mechanical stirring, take out the reactor and place it in the air ...

Embodiment 2

[0029] Depolymerization reaction of alkali lignin: the preparation process steps and parameters are the same as those in Example 1, except that the added catalyst is NaOH catalyst.

Embodiment 3

[0031]Depolymerization reaction of alkali lignin: the preparation process steps and parameters are the same as those in Example 1, except that the catalysts added are Pd / C catalyst and NaOH catalyst.

[0032] By comparing Examples 1-3, it can be found that: when using Pd / C or NaOH catalyst alone to depolymerize alkali lignin, the yield of the target product is not high, being 19.1% and 19.4% respectively, and the selectivity of a single product is relatively high. Low. When Pd / C and NaOH catalysts were used to synergistically decompose polyalkali lignin, the total yield of the target product was significantly increased to 37.5%. The specific data are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com