980 MPa-grade galvanized complex-phase steel and preparation method thereof

A 980mpa, multi-phase steel technology, applied in hot-dip galvanizing process, coating, improvement of process efficiency, etc., can solve the problems of insufficient yield strength and bendability of cold-rolled hot-dip galvanized steel, and achieve high bendability, high Effect of Yield Strength and Good Elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

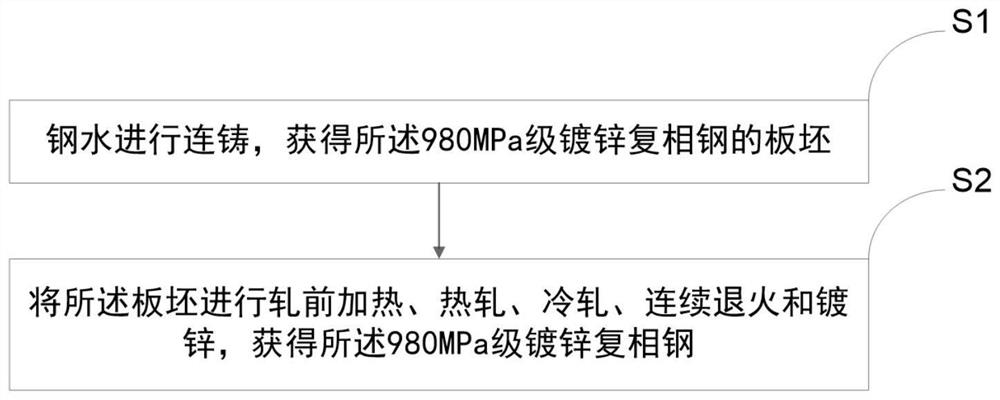

[0064] According to another typical embodiment of the present invention, a kind of preparation method of 980MPa grade galvanized multiphase steel is provided, such as figure 2 Shown, described preparation method comprises:

[0065] S1. The molten steel is continuously cast to obtain the slab of the 980MPa grade galvanized multiphase steel;

[0066] S2. Heating the slab before rolling, hot rolling, cold rolling, continuous annealing and galvanizing to obtain the 980MPa grade galvanized multiphase steel;

[0067] Wherein, the heating temperature before rolling is 1220-1280°C.

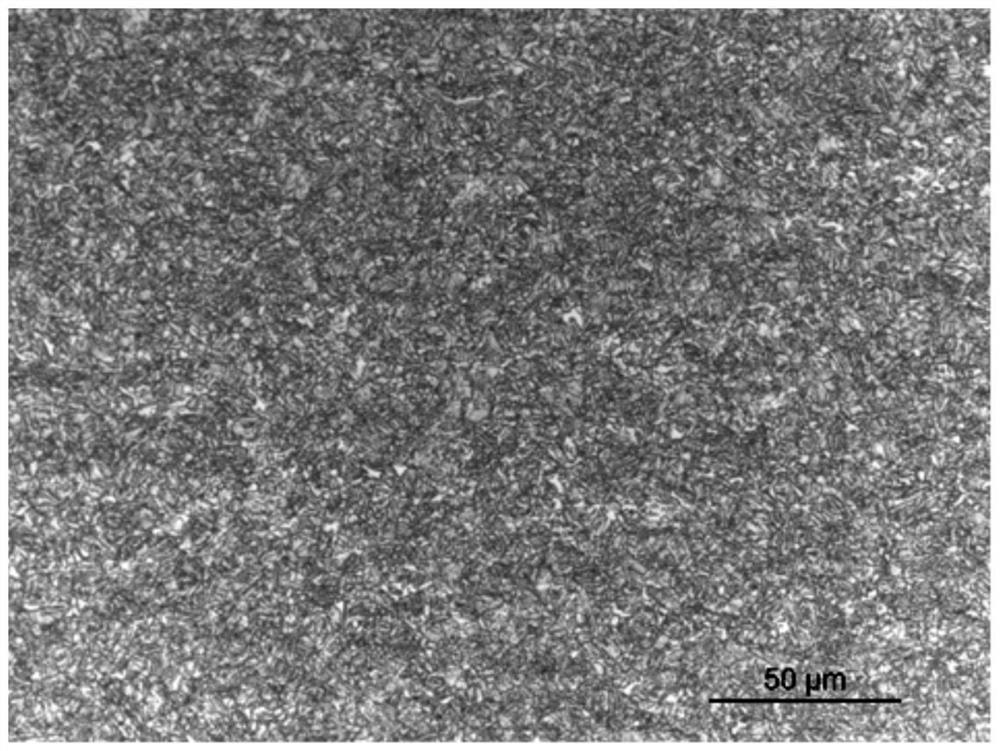

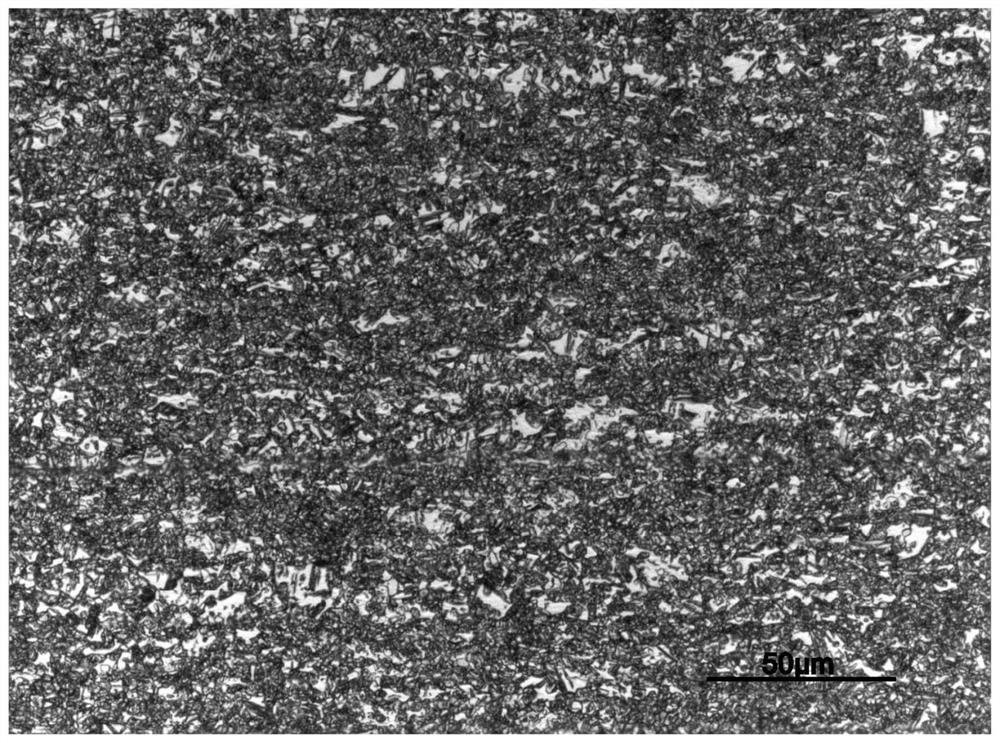

[0068] In the present invention, by improving the chemical composition of the slab and adopting the high-temperature heating-bainite transformation rapid cooling process mode, the hard bainite phase matrix, martensite, soft ferrite and retained austenite are obtained , the prepared multi-phase steel has high yield strength, matched with good elongation and high bendability, among them, if the heating t...

Embodiment approach

[0087] As an optional implementation, the galvanizing includes:

[0088] Heating the steel strip to 450°C-460°C, and then galvanizing;

[0089] Cool to 420-430°C after galvanizing, and then cool to 250-300°C at a rate of 6°C / s-9°C / s.

[0090] In this application, cool down to 420-430°C after galvanizing. In this process, the residence time of strip steel in the equalization section, furnace nose and zinc pot should be minimized by rapid induction heating, so as to avoid partial austenite decomposition at high temperature. ; and then cooled to 250-300°C at a rate of 6°C / s-9°C / s. During this process, part of the austenite phase transforms into a martensite phase.

[0091] A 980MPa grade galvanized multi-phase steel of the present application and its preparation method will be described in detail below in combination with examples, comparative examples and experimental data.

Embodiment

[0093] A kind of 980MPa grade galvanized multiphase steel, prepared by the following method:

[0094] (1) molten steel carries out continuous casting and obtains slab, and in mass fraction, the chemical composition of described slab is:

[0095] C: 0.10% to 0.12%, Si: 0.5 to 1.0%, Mn: 2.0% to 2.5%, Alt: 0.03% to 0.1%, Ti: 0.03% to 0.04%, P≤0.01%, S≤0.01%, N ≤0.004%, the balance is Fe and trace elements.

[0096] (2) Rolling: the slab is heated to 1250°C, then hot rolled, the final rolling temperature is 890°C, and the coiling temperature is 580°C, then cold rolled, and the cold rolling reduction is 56%.

[0097] (3) Continuous annealing:

[0098] Preheat the chilled coil obtained by cold rolling to 220°C at a rate of 8°C / s to obtain strip steel;

[0099] Heating the steel strip to 650°C to realize pre-oxidation at a heating rate of 6°C / s;

[0100] further heating the pre-oxidized steel strip to 850°C to 900°C at a rate of 1°C / s to 4°C / s, and keeping it warm for 60s to 150s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com