Photochromic polypropylene fiber and preparation method thereof

A polypropylene fiber and photochromic technology is applied in the field of preparation of photochromic polypropylene fibers and photochromic polypropylene fibers. , Not easy to yellow, reduce the effect of fiber background effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0039] Experimental Example 1: Masterbatch Preparation

[0040] In this experimental example, the photochromic masterbatch, antioxidant masterbatch, ultraviolet absorber masterbatch and light stabilizer masterbatch were prepared according to the masterbatch formula in Table 1 below.

[0041] Table I

[0042]

[0043] Note 1: The units are parts by weight or parts by weight

[0044] Note 2: The photochromic agent is the model NCC#12 purchased from Chongyu Technology, which has the structure of general formula (I-10)

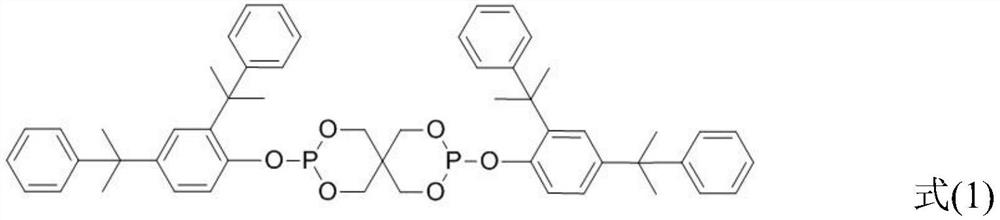

[0045] Note 3: The antioxidant is the model Revonox 608 purchased from Qitai Technology

[0046] Note 4: The dispersant is the model D1377E purchased from EMS-Griltex

[0047] Note 5: The ultraviolet light absorber is purchased from Yongguang Chemical Eversorb 41FD

[0048] Note 6: Light stabilizer is purchased from Yongguang Chemical Eversorb 94FD

experiment example 2

[0049] Experimental Example 2: Prepare photochromic polypropylene fiber and perform property test

[0050] In this experimental example, different combinations of ultraviolet light absorbers and light stabilizers and different ratios between the components were selected to prepare various photochromic polypropylene fibers as shown in Table 2 below. The fiber mechanical properties of these photochromic polypropylene fibers all have good spinning efficiency after testing.

[0051] Table II

[0052]

[0053] Note 1: The units in the composition formula are parts by weight

[0054] Note 2: The photochromic agent is the model NCC#12 purchased from Chongyu Technology, which has the structure of general formula (I-10)

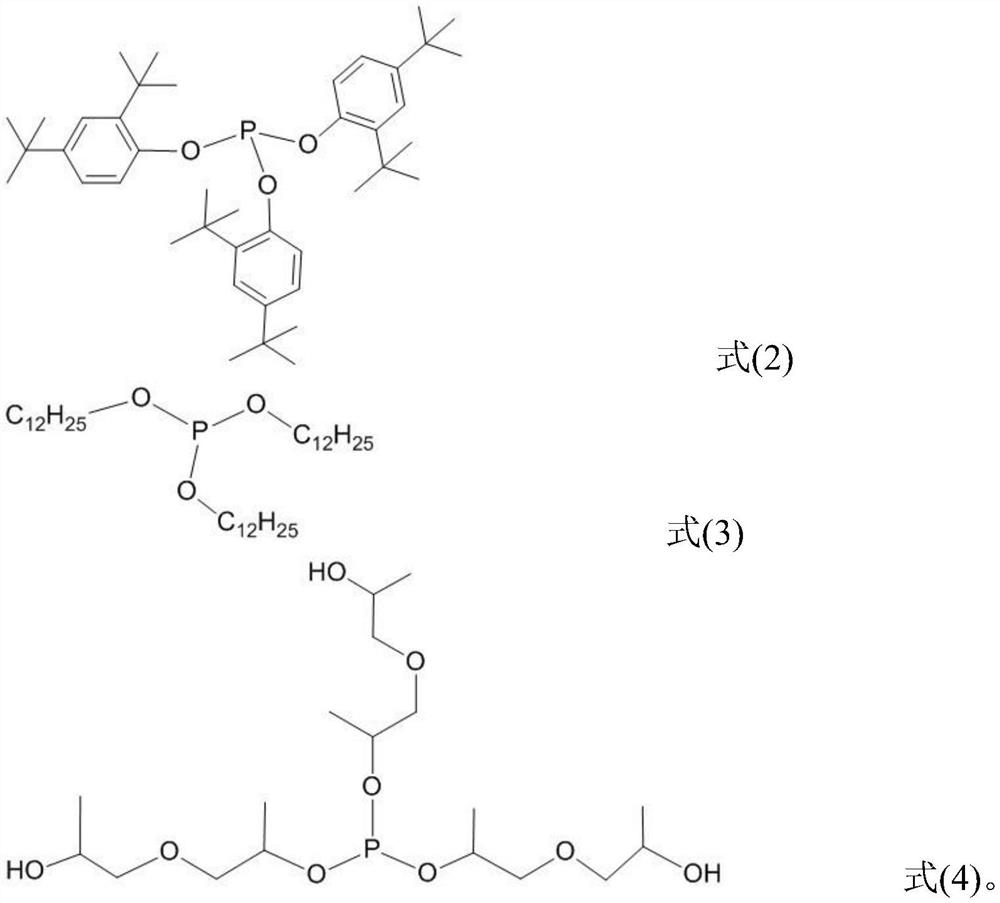

[0055] Note 3: The first UV absorber is Eversorb 12 purchased from Yongguang Chemical

[0056] Note 4: The second UV absorber is Eversorb 41FD purchased from Yongguang Chemical

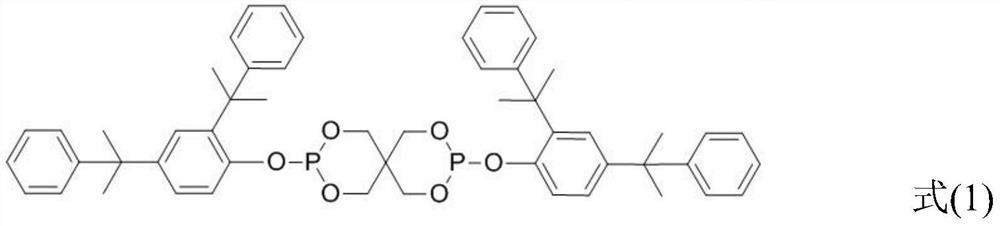

[0057] Note 5: The first photostabilizer is Eversorb 90 purchased from Yongguang C...

experiment example 3

[0060] Experimental Example 3: Ultraviolet Light Illumination Test

[0061] In this experimental example, ultraviolet light is used to irradiate these photochromic polypropylene fibers, and the discoloration effect and L*a*b* color space properties are shown in Table 3.

[0062] Table three

[0063]

[0064] Note 1: L* stands for brightness

[0065] Note 2: a* represents the opposite dimension of color, if the value of a* is positive (+), it means that the tested sample is reddish; if the value of a* is negative (-), it means that the tested sample is greenish

[0066] Note 3: b* represents the opposite dimension of color, if the value of b* is positive (+), it means that the tested sample is yellowish; if the value of b* is negative (-), it means that the tested sample is blue

[0067] Note 4: ◎ means excellent discoloration; △ means poor discoloration; X means no discoloration

[0068] It can be seen from Table 3 that the difference between Comparative Example 1 and Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com