High-gram-weight regenerated craft paper and preparation method thereof

A kraft cardboard, weight percentage technology, applied in the field of papermaking, can solve problems such as difficulties in regenerating kraft cardboard, many times of recycling, and short fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A kind of preparation method of high grammage regenerated kraft cardboard described in the second aspect of the present invention, it comprises the following steps:

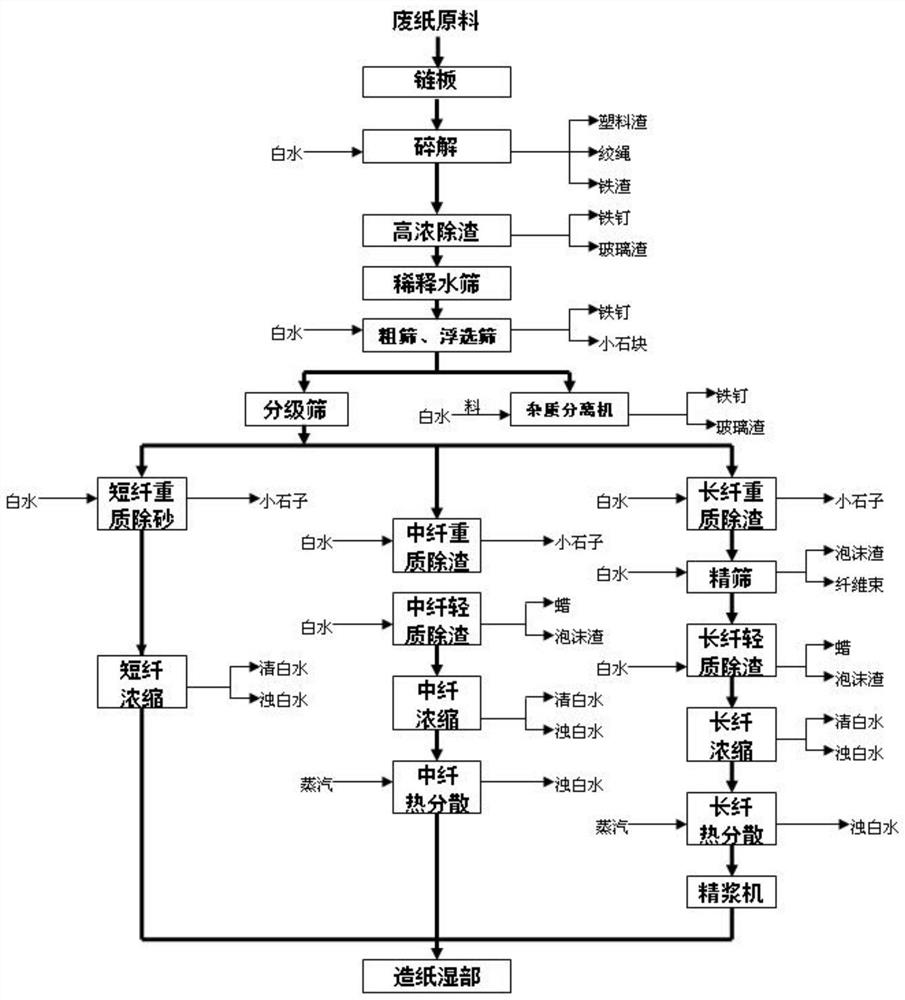

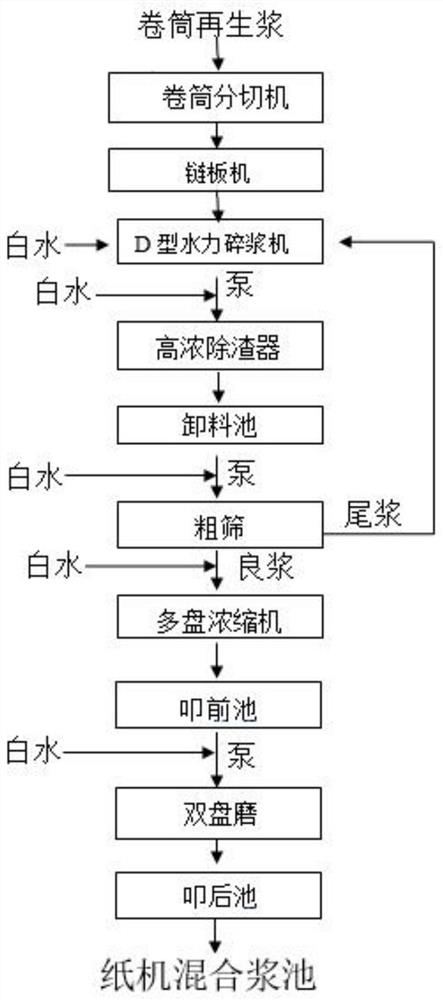

[0042] S10, preparation of national waste OCC pulp:

[0043] S101: After feeding, shredding, high-concentration slag removal, and coarse screening, the domestic OCC waste paper with a formula amount is subjected to fiber classification and sorting into national waste OCC long fiber, national waste OCC medium fiber and national waste OCC short fiber;

[0044] S102: After the national waste OCC long fiber is subjected to heavy deslagging, fine screening, light deslagging, multi-disk concentration, heat dispersion, and fine pulping, the national waste OCC long fiber pulp is obtained, and sent to the mixing pulp tank for blending pulp;

[0045] S103: After the national waste OCC medium fiber is subjected to heavy slag removal, light slag removal, multi-disc concentration, and heat dispersion, the national was...

Embodiment 1

[0077] Example 1 Slice Test of American Waste, European Waste and National Waste Raw Materials

[0078] In this example, the raw materials of American waste, European waste and domestic waste are crushed, slag removed, screened and purified, and then concentrated into a slurry, the slurry is decomposed to uniformity, and then the slices are tested separately, and the quantification of the slices is 100g / cm 2 , the test results are the average value after three determinations. The test results are shown in Table 1.

[0079] Table 1 The results of the copying test of American waste, European waste and national waste

[0080]

[0081] It can be seen from Table 1 that American waste fiber has good length and high fiber strength, and American waste OCC raw material sheets have high bursting strength and folding resistance; European waste is second in all aspects of performance; while domestic waste OCC raw material sheets The average length is low, the fiber bonding force is...

Embodiment 2

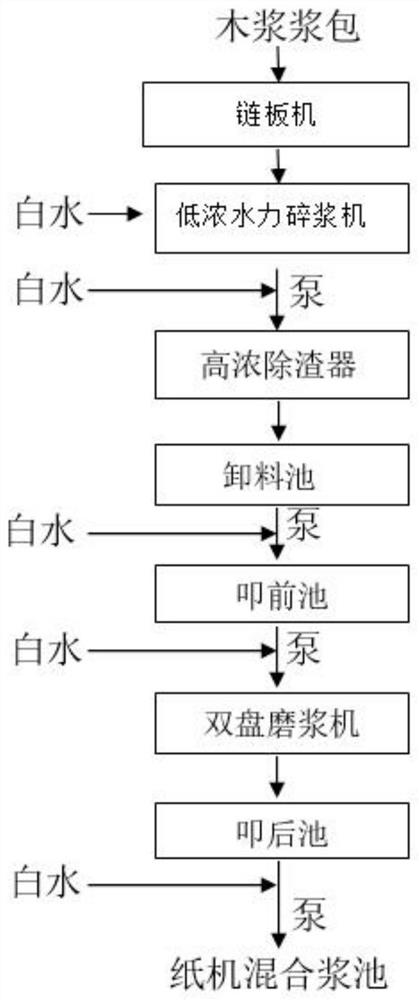

[0083] The sheet test of embodiment 2 wood pulp

[0084] In this embodiment, unbleached kraft softwood pulp (unbleached softwood pulp), unbleached kraft broadleaf pulp (unbleached eucalyptus pulp), reel recycled pulp (reel substitute wood pulp, fiber content is 100%) Chemical pulp) was crushed, slag removed, disc-milled and beaten into a slurry, and then the sheet test was carried out respectively, and the test results were shown in Table 2; at the same time, different wood pulps were carried out in the proportion sheet test, and the test results were shown in Table 3. Show. The test results are averaged after three determinations.

[0085] Sheet test results of table 2 wood pulp

[0086]

[0087] It can be seen from Table 2 that the unbleached kraft softwood pulp has the best burst index and folding strength. Although the bursting index and folding strength of unbleached eucalyptus pulp and reel wood pulp are lower than those of unbleached coniferous wood pulp, they are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com