Mining method for small-section high-grade ore body

A mining method and high-grade technology, applied in surface mining, underground mining, special mining, etc., can solve problems such as high mining cost, ore body depletion, waste of resources, etc., achieve a high degree of automation, solve depletion, and reduce work intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

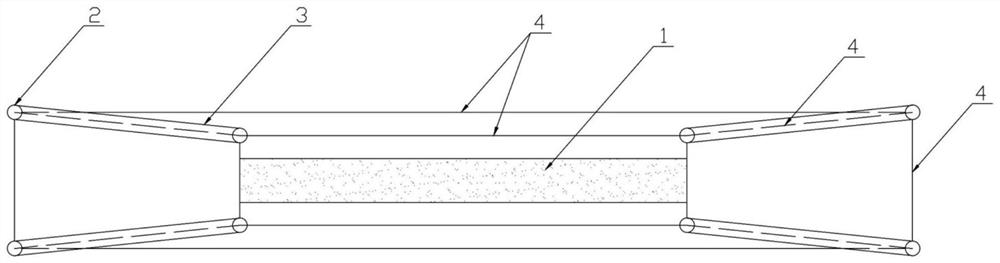

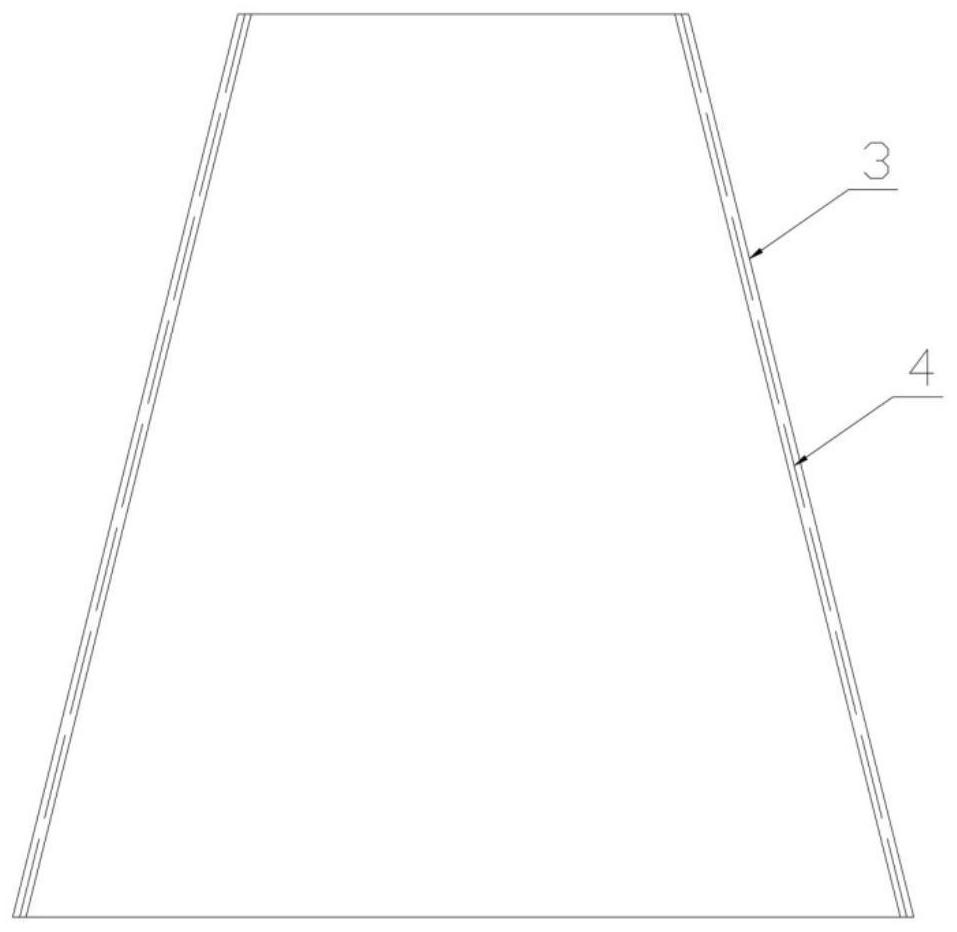

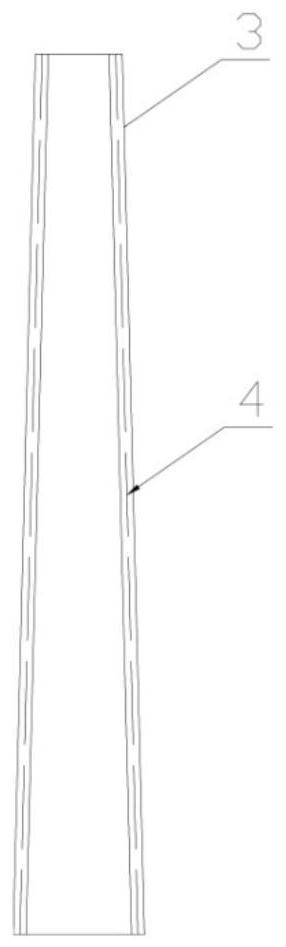

Image

Examples

Embodiment 1

[0027] A mining method for a small-section high-grade ore body, the specific steps are as follows:

[0028] (1) Selected orebodies: Most of the orebodies in a gold mine occur in pyrite-sericites, and part of them occur in pyrite-sericized granites. The ore is dominated by sulfide ore, and the depth of the oxidation zone is very shallow. The mineral composition of the primary ore: the metal minerals are mainly silver-gold ore and pyrite, and the secondary ones are natural gold, arsenopyrite, sphalerite, galena, chalcopyrite, pyrrhotite, limonite, Magnetite, etc.; the main gangue minerals are quartz, sericite, and residual feldspar, followed by carbonate minerals (calcite, dolomite, siderite, etc.). Valuable elements are mainly gold, accompanied by low-grade silver. The average ore grade is 2.0g / t, and the ore grade of some ore bodies is as high as 50g / t. A middle section is set every 40m downhole. A certain ore body occurs in the footwall of the main ore body, with a dip an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com