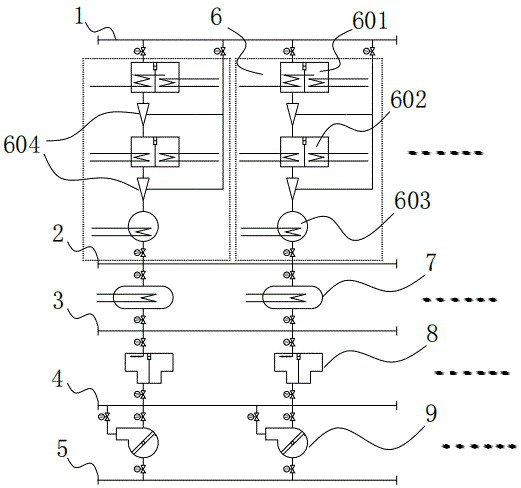

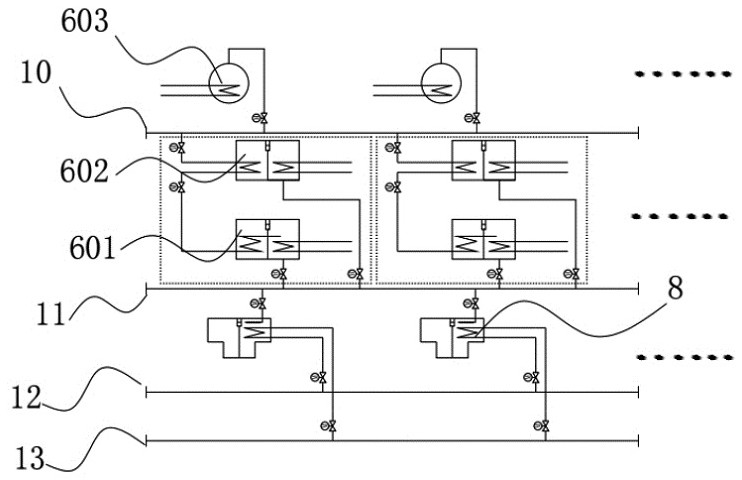

Header-system lithium bromide centralized cooling system and load distribution control method thereof

A centralized cooling and lithium bromide technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem that the economy and energy utilization efficiency of unit-based centralized refrigeration stations are difficult to achieve optimal conditions, and it is inconvenient to expand, repair and maintain. The problem of narrow operating conditions, etc., can improve the economy and energy utilization efficiency, the scheme is simple and practical, and the anti-disturbance ability can be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

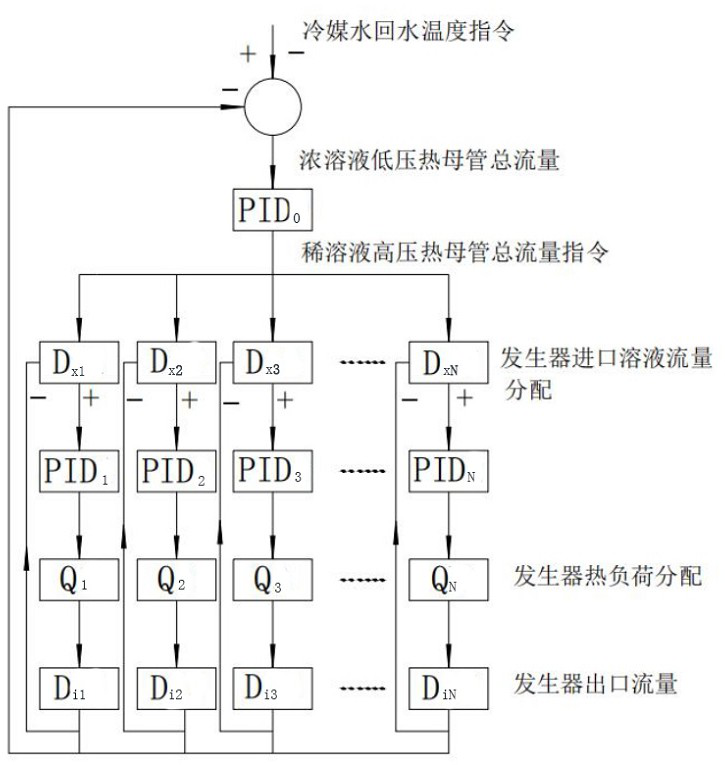

[0116] The load regulation model distributes the solution inlet flow of each generator module, and its distribution method is to use one generator to adjust substantially, and the rest of the generators that have been put into use are controlled in a manner of full-load operation;

[0117] The generator module is composed of three generators: high voltage generator, low voltage generator, and low and low voltage generator.

[0118] Mass balance equation for a single generator:

[0119]

[0120] In the formula, D x is the solution flow rate at the generator inlet, dD i / dτ is the flow differential at the outlet of the generator, ∑B i is the evaporation amount of refrigerant in the solution in the generator, ΣM i is the accumulated amount of solution in the generator.

[0121] Energy balance equation for a single generator:

[0122]

[0123] In the formula, Q x is the heat load of the generator, H 1 is the specific enthalpy of the generator inlet solution, H 0 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com