Time and temperature indicator based on polydiacetylene liposome and preparation method of time and temperature indicator

A technology of time temperature and acetylene ester, which is applied in the field of time temperature indicator based on polydiacetylene liposome and its preparation, can solve the problems of long-term storage and high application temperature without consideration, and achieve extended storage time, low detection temperature, Indicates the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 prepares the time temperature indicator based on polydiacetylene liposome

[0042] (1) Preparation of liposome / calcium alginate gel microspheres:

[0043] 10,12-Triscosadiynoic acid was removed with chloroform, then added deionized water to a concentration of 2 mM, dispersed by ultrasonic waves at 70°C for 10 minutes, and stored in a dark environment at 4°C for 24 hours. Obtain unpolymerized diacetylene liposome solution.

[0044] Stir and mix 15ml of unpolymerized liposome solution (concentration: 2mM) with 15ml of sodium alginate aqueous solution (mass fraction: 5%) and 140.5mg of calcium carbonate powder as the water phase; add 1.5 to 100mL of liquid paraffin g Span 80, stir evenly as the oil phase.

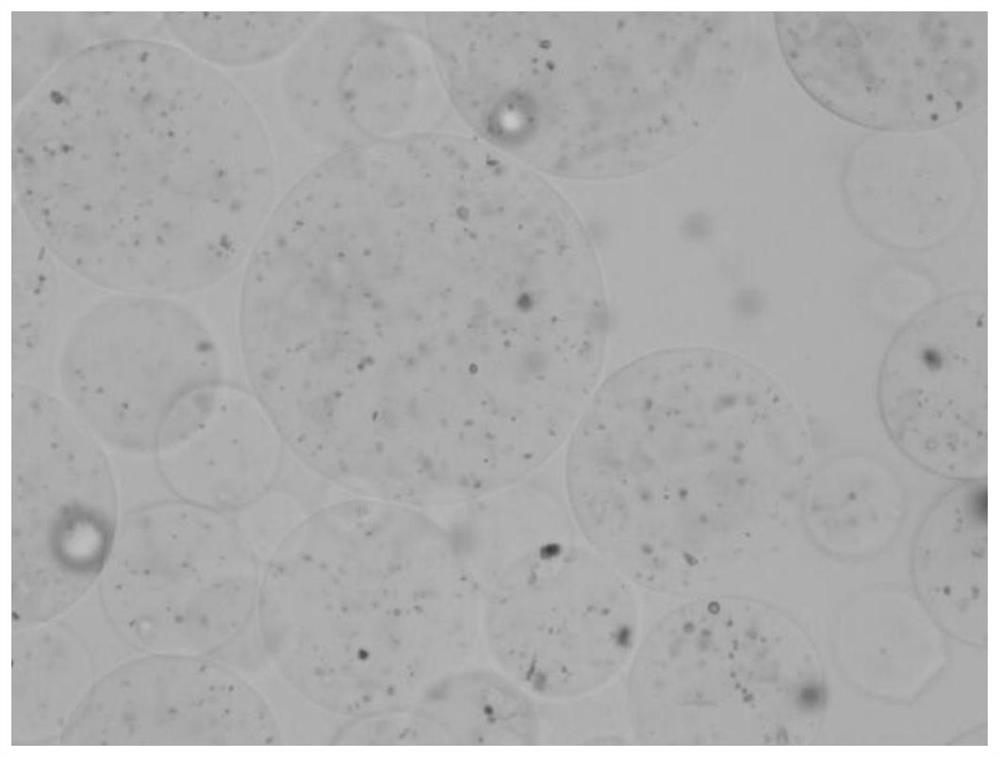

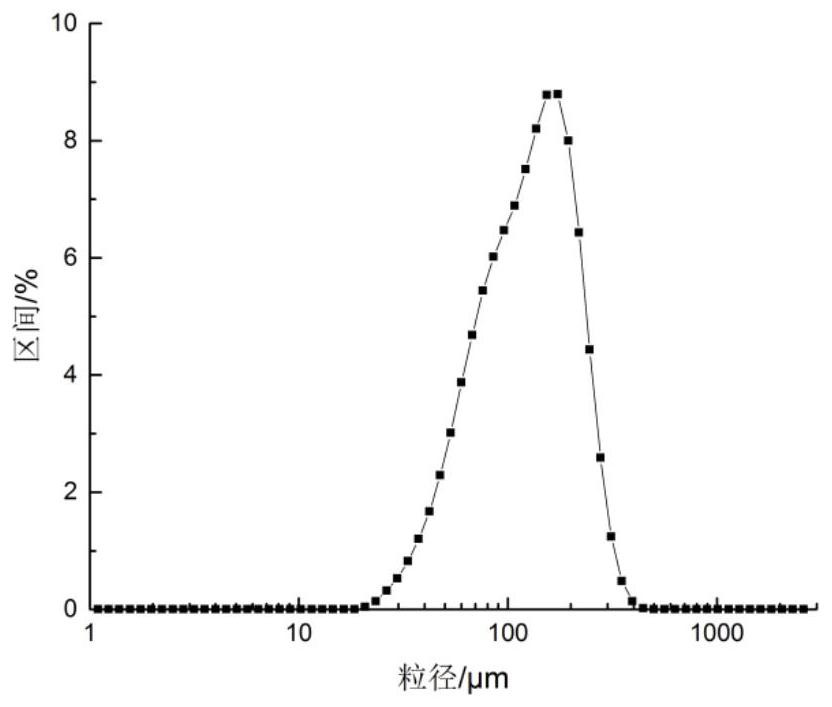

[0045] Under the condition of a stirring speed of 475r / min, the water phase was added dropwise into the oil phase and stirred for 30 min, and then 295 mg of glacial acetic acid was added to continue stirring for 30 min. After standing still, the microspher...

Embodiment 2

[0050] Embodiment 2 prepares the time temperature indicator based on polydiacetylene liposome

[0051] (1) Preparation of liposome / calcium alginate gel microspheres:

[0052] 10,12-Tracosadiynoic acid was removed by chloroform, then added to deionized water at a concentration of 2mM, dispersed by ultrasonic waves at 80°C for 10min, and stored in a dark environment at 4°C for 24h to obtain Unpolymerized diacetylenic liposome solution.

[0053] Stir and mix 15ml of unpolymerized liposome solution (concentration: 2mM) with 15ml of sodium alginate aqueous solution (mass fraction: 5%) and 140.5mg of calcium carbonate powder as the water phase; add 1.5 to 100mL of liquid paraffin g Span 80, stir evenly as the oil phase.

[0054] Under the condition of a stirring speed of 475r / min, the water phase was added dropwise into the oil phase and stirred for 30 min, and then 295 mg of glacial acetic acid was added to continue stirring for 30 min. After standing still, the microspheres in ...

Embodiment 3

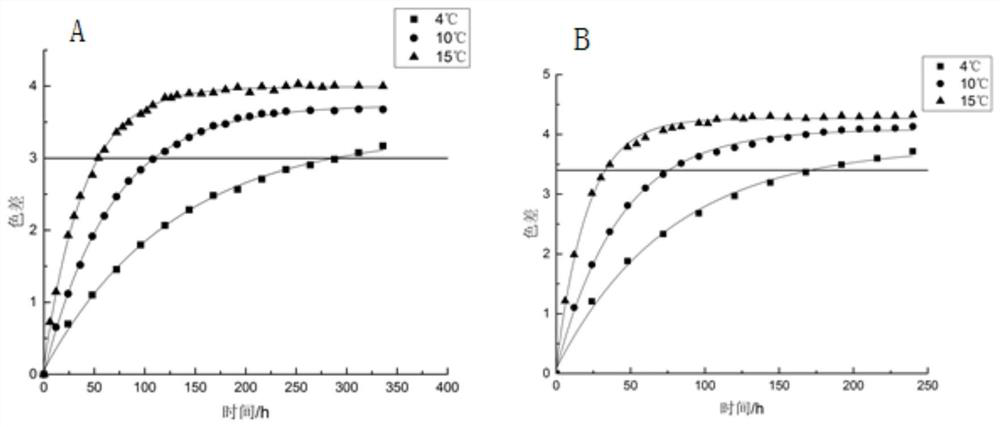

[0057] The kinetic model of embodiment 3 time temperature indicator:

[0058] The TTI prepared in Example 1-2 was placed at 4°C, 10°C, and 15°C, and the color difference value was measured, and the color difference value of TTI was recorded by a color difference meter, which was studied as a kinetic parameter of TTI.

[0059] The calculation formula of the color difference value is shown in formula (1):

[0060]

[0061] Where: △L*=L*-L 0 *、△a*=a*-a 0 *、△b*=b*-b 0 *; L*, a*, b* are the lightness value, red-green value, yellow-blue value after TTI reaction; L 0 *、a 0 *,b 0 * is the initial value of lightness, red-green degree, yellow-blue degree; ΔE is the color difference value of TTI.

[0062] The kinetic parameters of TTI have a significant exponential relationship with time, as shown in formula (2):

[0063] F(X)=a-b×exp(-kt) (2)

[0064] In the formula: F(X) is the TTI color difference value; a, k and b are fitting function parameters respectively, and k is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com