Method for constructing microscopic reaction model in polycrystalline silicon efficient deposition process

A deposition process and reaction model technology, applied in the fields of instrumentation, computational theoretical chemistry, informatics, etc., can solve the problems that macroscopic simulation methods cannot simulate chemical reaction processes, it is difficult to directly characterize the dynamic evolution of products, and lack of in-situ detection, etc., to achieve Flexible setting of model parameters, increased ease of operation, and high modeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

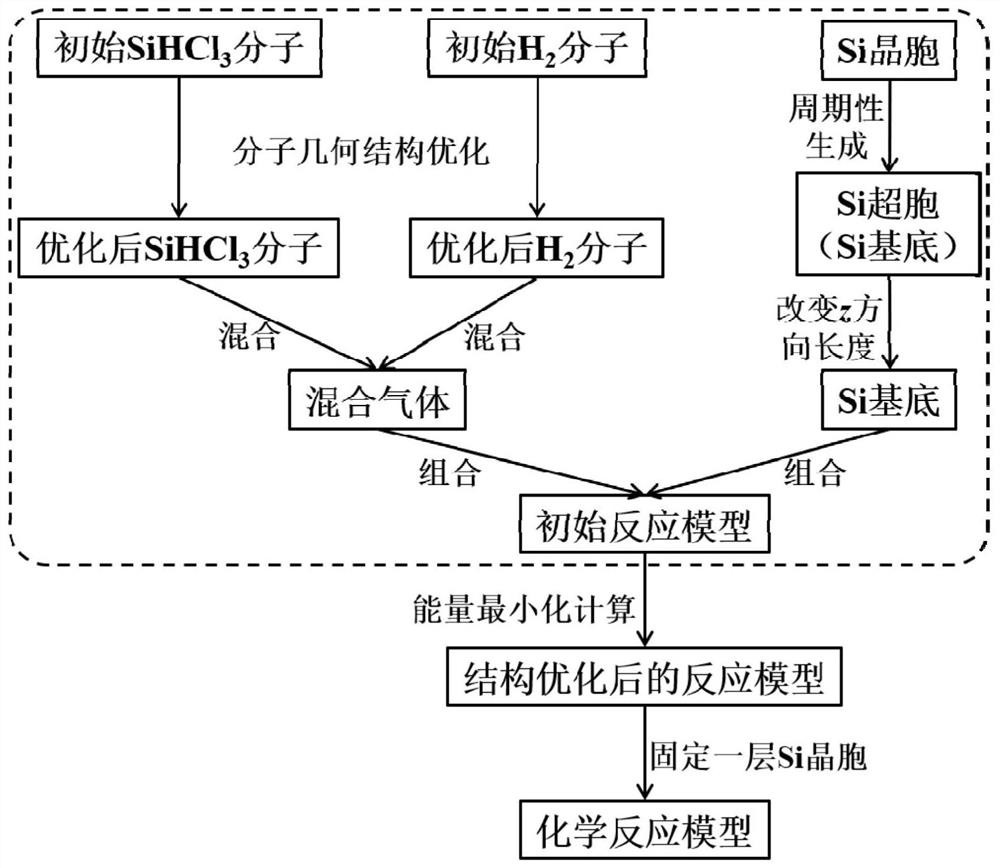

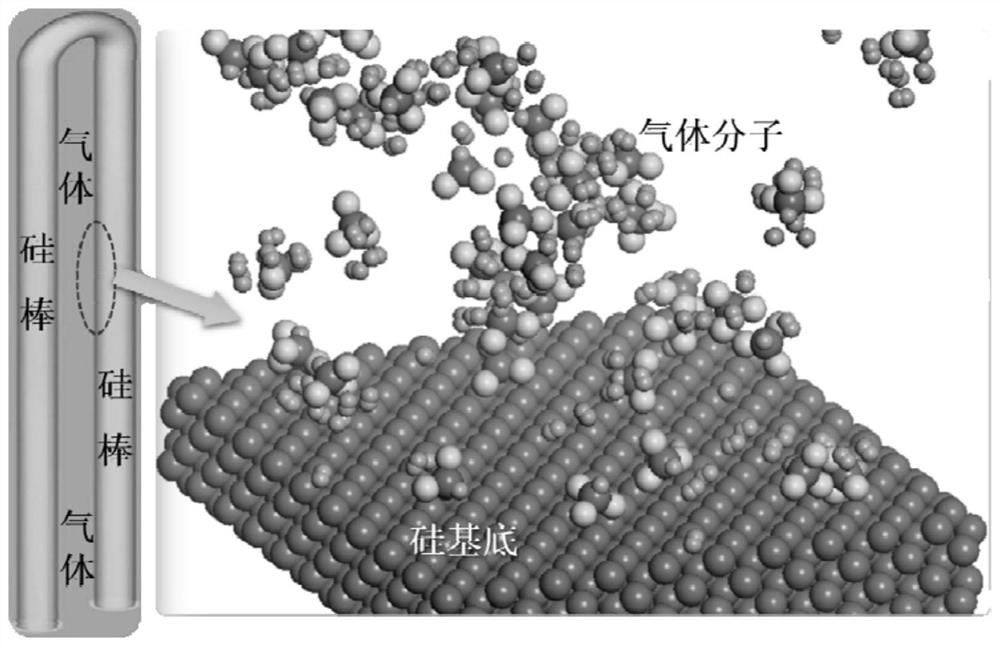

[0045] Applying MS software, first construct a single SiHCl 3 and H 2 Molecules; after the geometric structure optimization of the two molecules by the Universal force field, the SiHCl 3 and H 2 Molecule according to gas density is 0.001g / cm 3 Mixed, where SiHCl 3 and H 2 The number of molecules is 10 and 100 respectively, and the gas phase mixed gas model is obtained Import a single Si unit cell into MS through the operation steps of File→Import→Structures→ceramics→Si.msi in the menu bar 26 Si unit cells are periodically generated in the x and y directions, and 2 Si unit cells are periodically generated in the z direction to construct a Si supercell containing 26×26×2 Si unit cells; modify the Si supercell in z The length of the direction is Simulation box for building chemical reaction models The mixed gas is introduced above the center of the xy plane of the Si substrate to obtain the initial structure of the chemical reaction model, where the vacuum layer bet...

Embodiment 2

[0047] Applying MS software, first construct a single SiHCl 3 and H 2 Molecules; after the geometric structure optimization of the two molecules by the Universal force field, the SiHCl 3 and H 2 Molecule according to gas density is 0.001g / cm 3 Mixed, where SiHCl 3 and H 2 The number of molecules is 20 and 200 respectively, and the gas phase mixed gas model is obtained Import a single Si unit cell into MS through the operation steps of File→Import→Structures→ceramics→Si.msi in the menu bar 32 Si unit cells are periodically generated in the x and y directions respectively, and 2 Si unit cells are periodically generated in the z direction to construct a Si supercell containing 32×32×2 Si unit cells; modify the Si supercell in z The length of the direction is Simulation box for building chemical reaction models The mixed gas is introduced above the center of the xy plane of the Si substrate to obtain the initial structure of the chemical reaction model, where the vac...

Embodiment 3

[0049] Applying MS software, first construct a single SiHCl 3 and H 2Molecules; after the geometric structure optimization of the two molecules by the Universal force field, the SiHCl 3 and H 2 Molecules according to the gas density of 0.005g / cm 3 Mixed, where SiHCl 3 and H 2 The number of molecules is 30 and 300 respectively, and the gas phase mixed gas model is obtained Import a single Si unit cell into MS through the operation steps of File→Import→Structures→ceramics→Si.msi in the menu bar 22 Si unit cells are periodically generated in the x and y directions, and 2 Si unit cells are periodically generated in the z direction to construct a Si supercell containing 22×22×2 Si unit cells; modify the Si supercell in z The length of the direction is Simulation box for building chemical reaction models The mixed gas is introduced above the center of the xy plane of the Si substrate to obtain the initial structure of the chemical reaction model, where the vacuum layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com