FDTD-based structural color microsphere shell preparation method

A technology for structural color and microspheres, applied in the fields of instrumentation, computer material science, design optimization/simulation, etc., can solve the problems of complex structural color material process, unprepared structured light material, complex structural color analysis, etc., to facilitate the analysis of light. The effect of interference, high controllability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0029]

[0030] A method for preparing a structurally colored microsphere shell based on FDTD in this embodiment comprises the following steps:

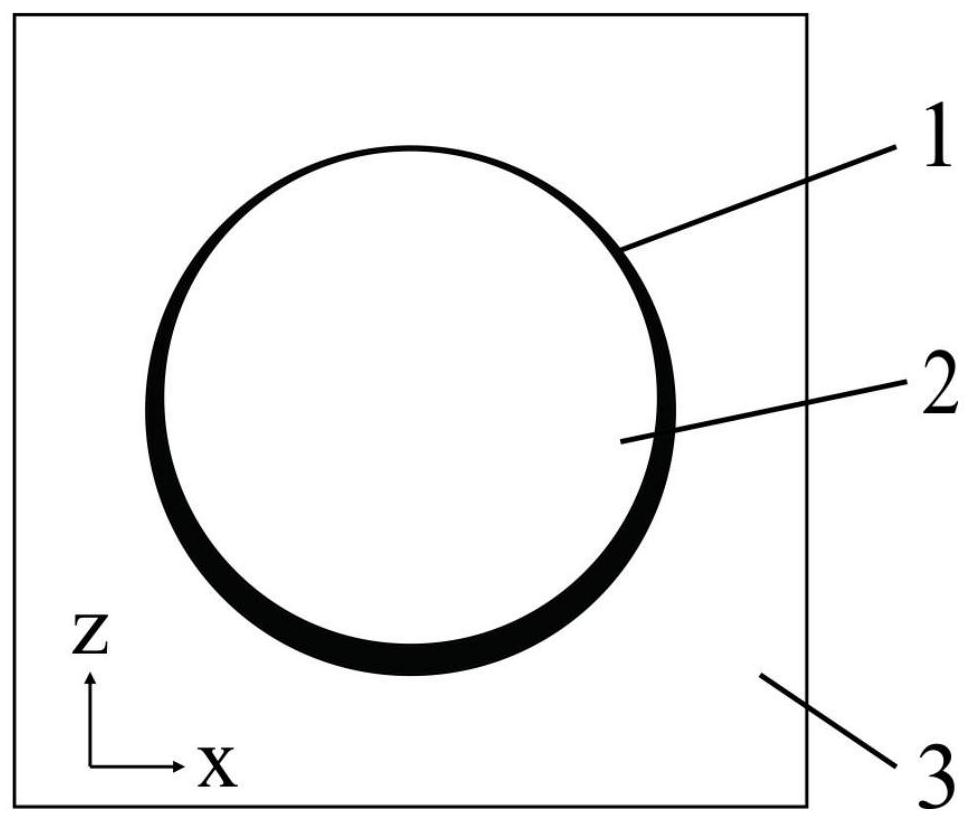

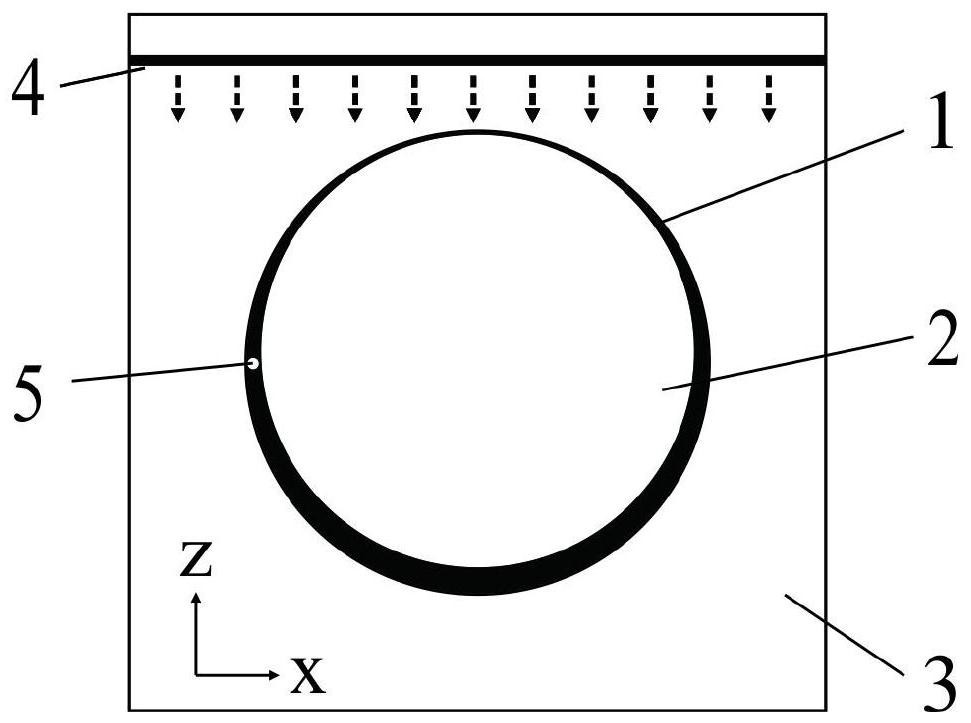

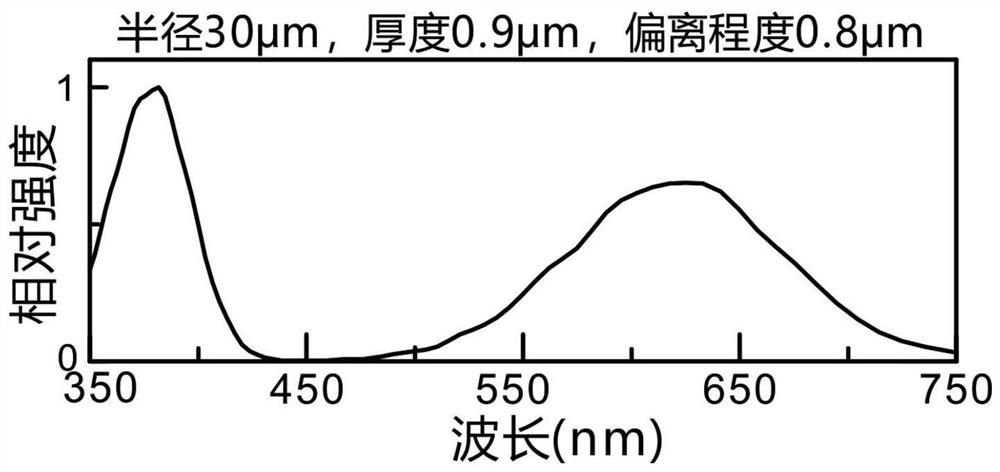

[0031] Step 1. Design the structure of the structural color microsphere shell, including the inner phase, the shell covering the inner phase, and the outer phase outside the shell, set the refractive index of the inner phase, the shell layer, and the outer phase, and calculate The structure of the microsphere shell is constructed to obtain the microsphere shell model. By changing the structural parameters of the microsphere shell model, the reflection spectrum of the structural color microsphere shell is simulated to establish the relationship between the structural parameters and the structural color, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com