Full-automatic electronic component packaging process

A technology of electronic components and packaging technology, which is applied in the field of fully automatic electronic component packaging technology, can solve the problems of high manpower and material resources, falling off of electronic components, poor packaging effect, etc., so as to save manpower and material resources, improve quality and precision, and not easy to fall off and layered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

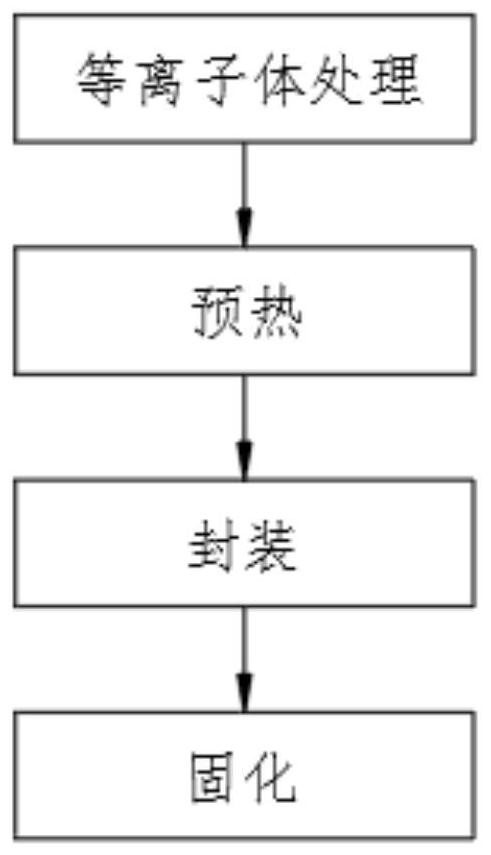

[0038] A fully automatic electronic component packaging process, comprising the steps of:

[0039] S1. Put the electronic components and packaging substrates into a vacuum chamber, and perform plasma treatment on the electronic components and packaging substrates in the presence of a gas containing an organosilicon compound;

[0040] S2. Preheating the electronic components after plasma treatment;

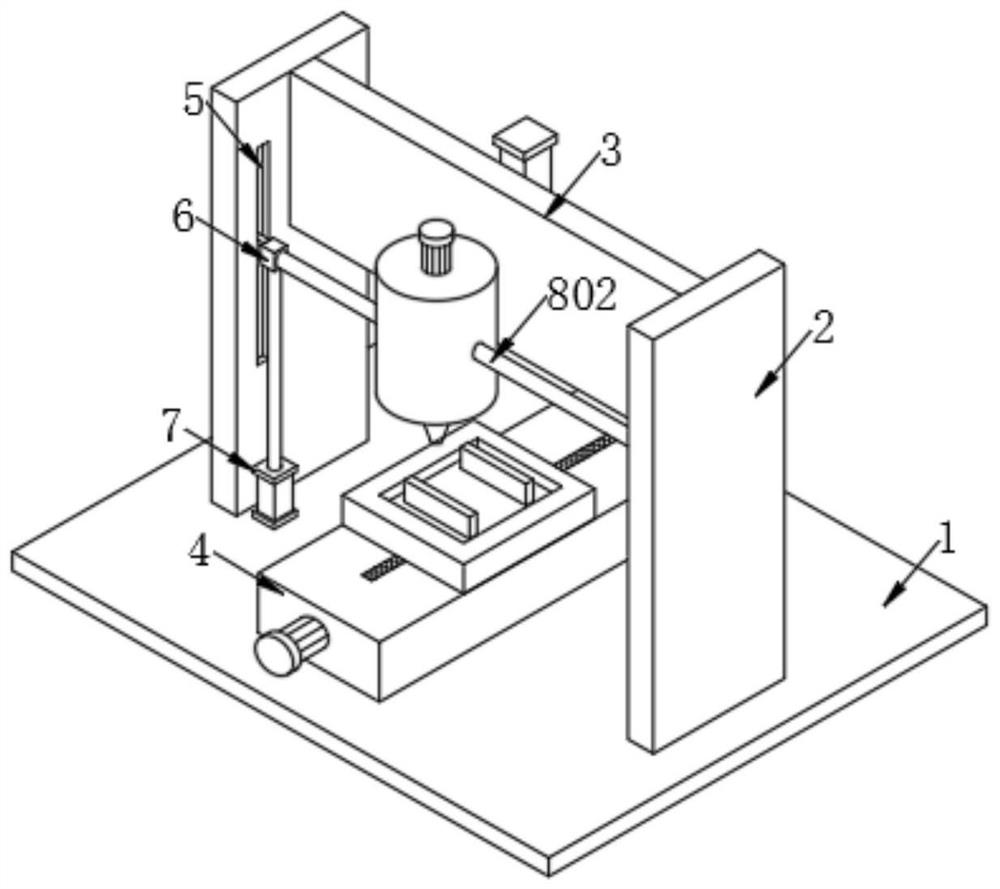

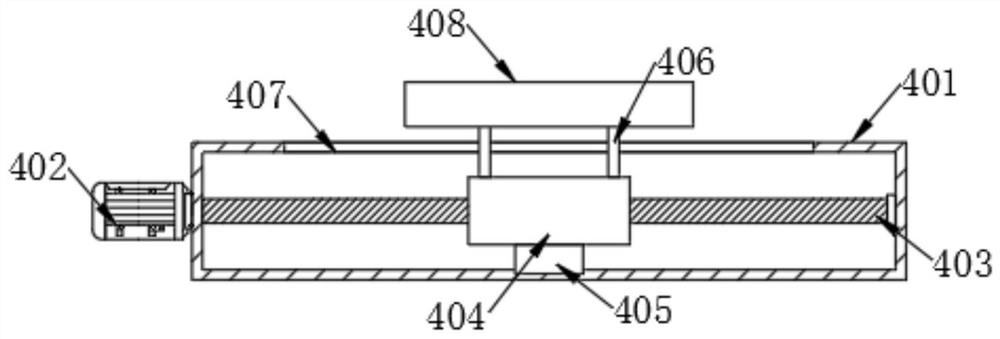

[0041] S3. Put the preheated electronic components on the suction cup 11 of the packaging equipment, use the dispensing mechanism 8 to apply the epoxy resin adhesive on the packaging substrate, and move the packaging substrate to the dispensing mechanism sequentially through the clamping mechanism 4 8 and under the suction cup 11, the electronic components are bonded to the packaging substrate through an epoxy resin adhesive;

[0042] S4. Put the packaging substrate bonded with the electronic components in a curing box for curing to complete the packaging process.

[0043] The pr...

Embodiment 2

[0048] A fully automatic electronic component packaging process, comprising the steps of:

[0049] S1. Put the electronic components and packaging substrates into a vacuum chamber, and perform plasma treatment on the electronic components and packaging substrates in the presence of a gas containing an organosilicon compound;

[0050] S2. Preheating the electronic components after plasma treatment;

[0051] S3. Put the preheated electronic components on the suction cup 11 of the packaging equipment, use the dispensing mechanism 8 to apply the epoxy resin adhesive on the packaging substrate, and move the packaging substrate to the dispensing mechanism sequentially through the clamping mechanism 4 8 and under the suction cup 11, the electronic components are bonded to the packaging substrate through an epoxy resin adhesive;

[0052] S4. Put the packaging substrate bonded with the electronic components in a curing box for curing to complete the packaging process.

[0053] The pr...

Embodiment 3

[0058] A fully automatic electronic component packaging process, comprising the steps of:

[0059] S1. Put the electronic components and packaging substrates into a vacuum chamber, and perform plasma treatment on the electronic components and packaging substrates in the presence of a gas containing an organosilicon compound;

[0060] S2. Preheating the electronic components after plasma treatment;

[0061] S3. Put the preheated electronic components on the suction cup 11 of the packaging equipment, use the dispensing mechanism 8 to apply the epoxy resin adhesive on the packaging substrate, and move the packaging substrate to the dispensing mechanism sequentially through the clamping mechanism 4 8 and under the suction cup 11, the electronic components are bonded to the packaging substrate through an epoxy resin adhesive;

[0062] S4. Put the packaging substrate bonded with the electronic components in a curing box for curing to complete the packaging process.

[0063] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com