Epoxy resin high-thermal-conductivity composite material and preparation method thereof

A technology of epoxy resin and composite material, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of the decline of mechanical properties of composite materials with thermal conductive filler filling amount, and achieve good process operability, maintain insulation properties, mechanical properties, etc. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

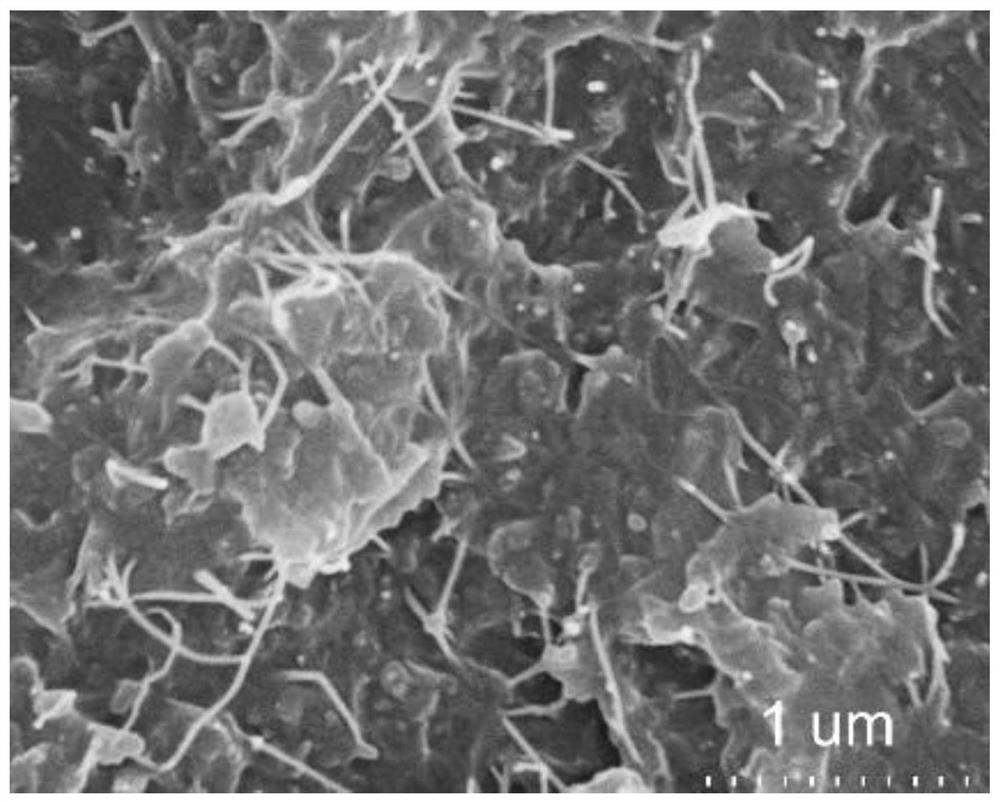

Image

Examples

Embodiment 1

[0020] (1) Add 2g of boron nitride nanotubes into 5mol / L NaOH solution, stir and reflux at 120°C for 24h, centrifuge, wash and dry;

[0021] (2) Prepare the boron nitride nanotubes treated in the above step (1) into a 2g / L aqueous dispersion of boron nitride nanotubes, and then add aminopropyltrimethoxysilane with a mass ratio of 2%, 80 Stir and reflux at ℃ for 12h, centrifuge, wash and dry;

[0022] (3) The aminopropyltrimethoxysilane-modified boron nitride nanotubes prepared in step (2) were dispersed in acetone by high-speed stirring, and then 14.4g of bisphenol A epoxy resin and 3.6g of aromatic amine curing agent were added, Ultrasonic treatment for 70 minutes to obtain a boron nitride nanotube dispersion;

[0023] (4) Heat and vacuum the dispersion liquid prepared in step (3) to remove acetone and air bubbles, and finally carry out thermal curing reaction. The heat curing condition is 80°C for 24 hours at a constant temperature, and then 130°C for 12 hours to obtain a ...

Embodiment 2

[0026] (1) Add 1g of boron nitride nanotubes to 5mol / L NaOH solution, stir and reflux at 120°C for 12h, centrifuge, wash and dry;

[0027] (2) Prepare the boron nitride nanotubes treated in the above step (1) into a 1g / L aqueous dispersion of boron nitride nanotubes, and then add aminopropyltrimethoxysilane with a mass ratio of 1%, 80 Stir and reflux at ℃ for 12h, centrifuge, wash and dry;

[0028] (3) The aminopropyltrimethoxysilane-modified boron nitride nanotubes prepared in step (2) were dispersed in acetone by high-speed stirring, and then 15.2g of bisphenol F epoxy resin and 3.8g of aromatic amine curing agent were added, Ultrasonic treatment for 60 minutes to obtain a boron nitride nanotube dispersion;

[0029] (4) Heat and vacuum the dispersion liquid prepared in step (3) to remove acetone and air bubbles, and finally carry out thermal curing reaction. The heat curing condition is 80°C for 24 hours at a constant temperature, and then 130°C for 12 hours to obtain a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com