A kind of phase change microcapsule with controllable supercooling degree and its preparation method and application

A phase-change microcapsule and supercooling technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of reducing the supercooling degree of microcapsules, reducing the supercooling degree, agglomeration and stratification, etc. Achieve the effect of enhancing cycle utilization, preventing capsule leakage, and improving repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

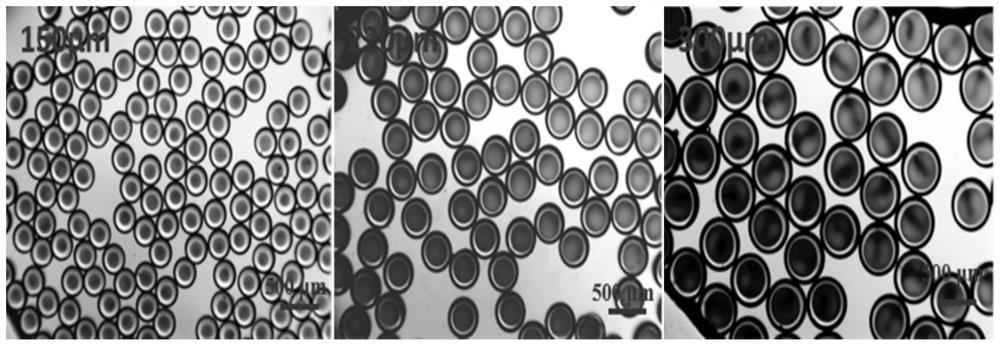

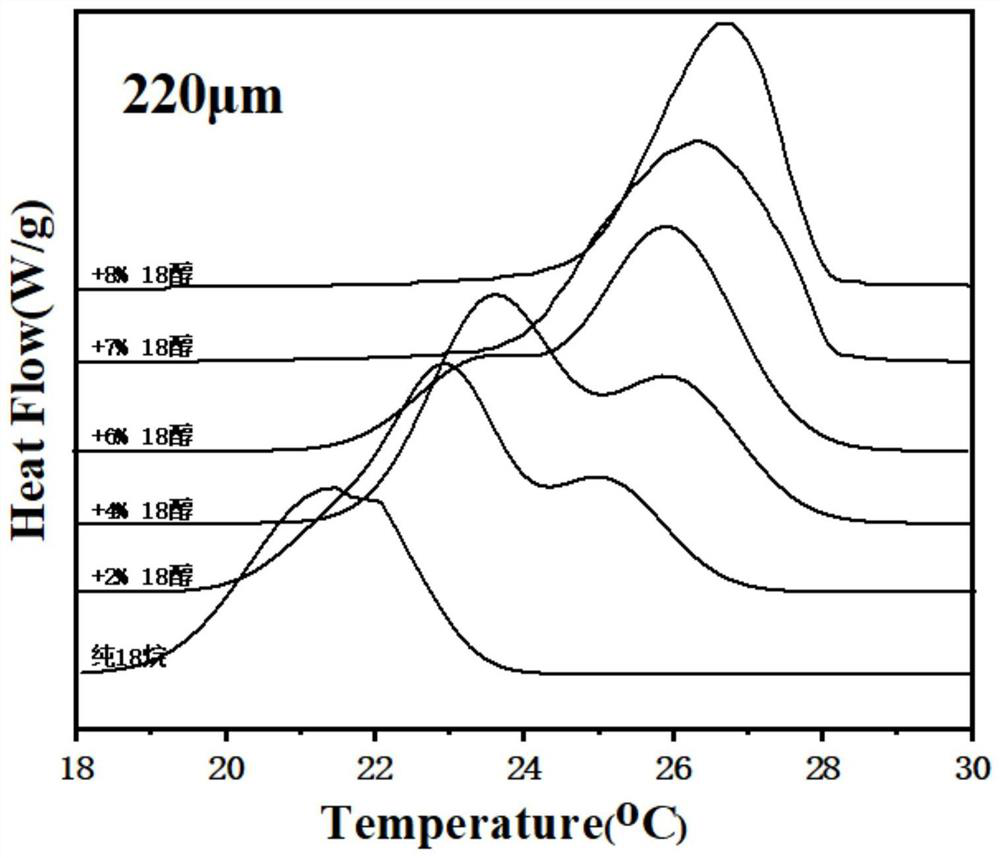

[0031] Raw material preparation: Add 10 g of polyvinyl alcohol (PVA) to 500 mL of deionized water, and continue stirring for 40 min at 70° C. and 1000 r / min to obtain an aqueous PVA solution as an aqueous fluid. Weigh 9.7g of 1,6-hexanediol diacrylate (HDDA), add 0.1g of surfactant (span80) and 0.2g of photoinitiator (2-hydroxy-2-methylpropiophenone) , placed on a magnetic stirrer at 25°C and stirred at 1000r / min for 20min as an intermediate phase fluid. Weigh eleven groups of octadecane phase change materials with a mass of 10g, and add 0g, 0.1g, 0.2g, 0.3g, 0.4g, 0.5g, 0.6g, 0.7g, 0.8g, 0.9g, 1g respectively. Stearyl alcohol was placed on a magnetic stirrer under the conditions of 70° C. and 1000 r / min for continuous stirring for 30 min as an oil phase fluid.

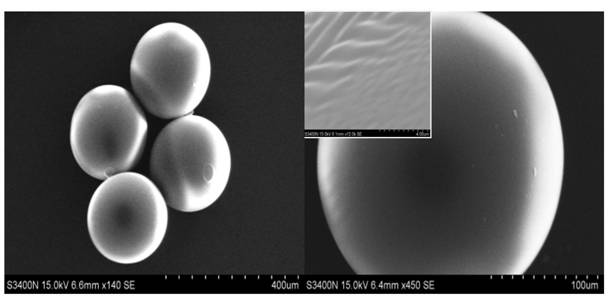

[0032]Microcapsules were prepared by using the double emulsified glass capillary microfluidic chip in the Chinese invention patent with the application number of 201811008829.0 as the microfluidic chip: the water pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com