Vapor pressure assisted preparation method of copper-based halide material and product and application thereof

A halide, copper-based technology, applied in the field of polycrystalline material preparation, can solve problems such as instability of white light, and achieve the effects of good air stability, long device service life and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

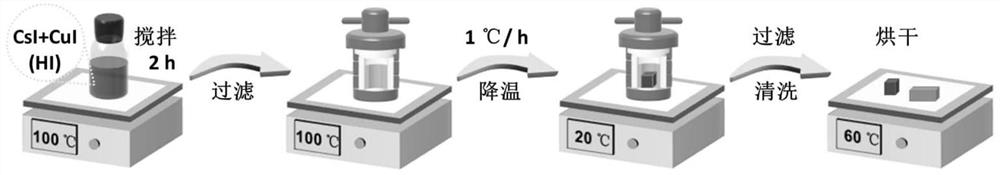

[0031] Prepare a white light polycrystalline material cesium copper iodine, the preparation process is as follows figure 1 As shown, the specific steps are as follows:

[0032] (1) Select 2.597g (10mmol) cesium iodide (CsI) and 1.904g (10mmol) cuprous iodide (CuI) and add it to 20mL hydroiodic acid (HI), place it on a heating table, add magnets, and turn on the magnetic force Stirrer, heated to 105 ° C, heated for more than 2 hours until cesium iodide (CsI) and cuprous iodide (CuI) were fully dissolved to form a solution;

[0033] (2) The solution fully dissolved in step (1) is filtered with a 0.45 μm polytetrafluoroethylene filter head, and the clear solution obtained is placed in a clean polytetrafluoroethylene-lined bottle and sealed in a reaction kettle. Then place the reaction kettle in a programmable cooling heating platform or an oven to perform a cooling reaction at a rate of 0.5°C / h, and the white light polycrystalline cesium copper iodine material can be obtained wh...

Embodiment 2

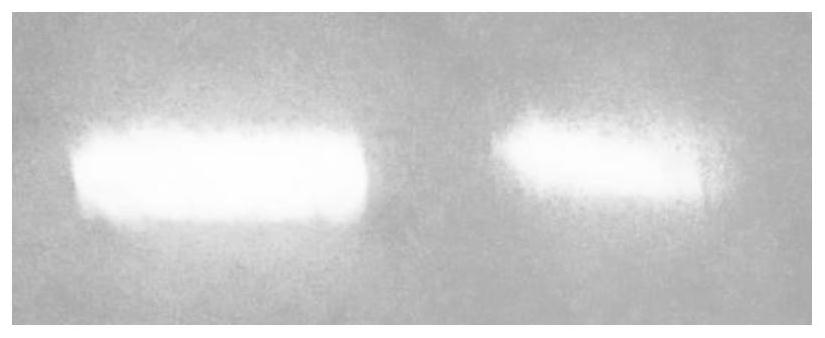

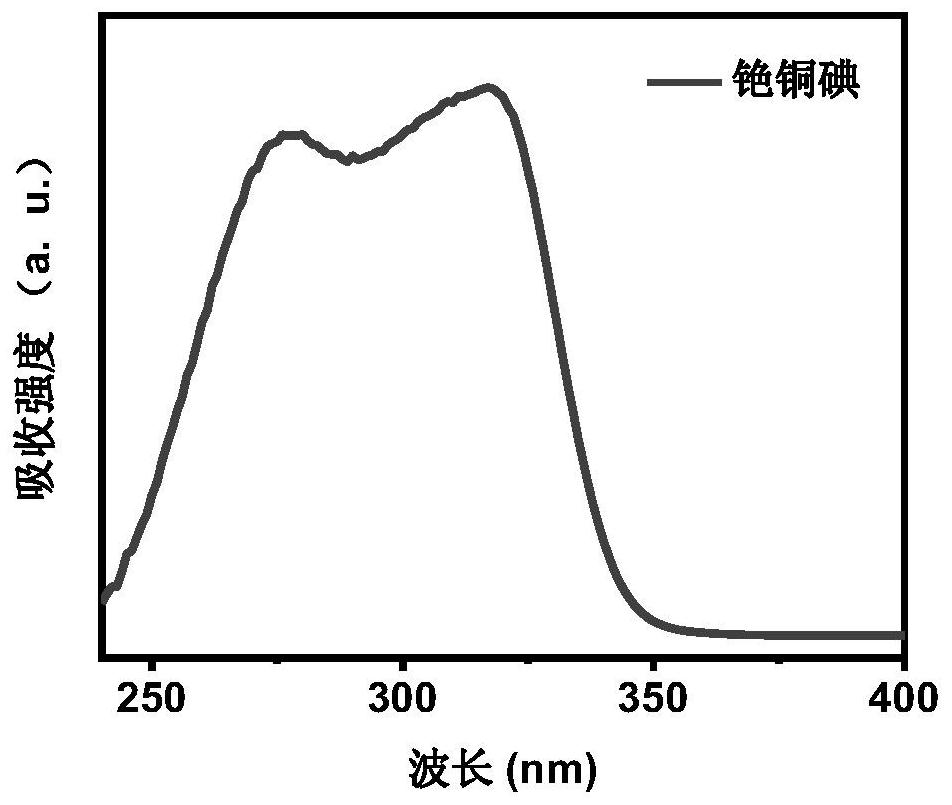

[0035] Preparation of a blue light single crystal material Cs 3 Cu 2 I 5 , the specific steps are as follows:

[0036] (1) Select 1.948g (7.5mmol) cesium iodide (CsI) and 0.952g (5mmol) cuprous iodide (CuI) and add it to 20mL hydroiodic acid (HCl), place it on a heating table, and add a magnet , turn on magnetic stirring, heat to 100° C., and heat for more than 2 hours until cesium iodide (CsI) and cuprous iodide (CuI) are completely dissolved to form a solution;

[0037] (2) Filter the solution fully dissolved in step (1) with a 0.45 μm polytetrafluoroethylene filter head, and place the clear solution obtained in a clean polytetrafluoroethylene-lined bottle and seal it in a reaction kettle. Then place the reaction kettle on a programmable cooling platform to cool down at a rate of 1°C / h, and then cool down to room temperature to obtain the blue light single crystal material Cs 3 Cu 2 I 5 .

Embodiment 3

[0039] Preparation of a yellow light single crystal material CsCu 2 I 3 , the specific steps are as follows:

[0040] (1) Select 1.298g (5mmol) cesium iodide (CsI) and 1.904g (10mmol) cuprous iodide (CuI) and add it to 20mL hydroiodic acid (HI), place it on the heating table, add magnets, and turn on the magnetic force Stirrer, heated to 130 ° C, heated for more than 2 hours until cesium iodide (CsI) and cuprous iodide (CuI) were completely dissolved to form a solution;

[0041] (2) Filter the solution fully dissolved in step (2) with a 0.45 μm polytetrafluoroethylene filter head, and place the obtained clear solution in a clean polytetrafluoroethylene-lined bottle, then place the polytetrafluoroethylene inner bottle The liner bottle is placed on a heat table with programmable cooling at a rate of 1°C / h for cooling reaction, and the yellow light single crystal material CsCu can be obtained when the temperature is lowered to room temperature. 2 I 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com