A high-efficiency and energy-saving straw powder drying device

A straw powder, high-efficiency and energy-saving technology, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of inconvenient screening of caking blocks, incomplete drying, etc., to prolong drying time, improve drying effect, The effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

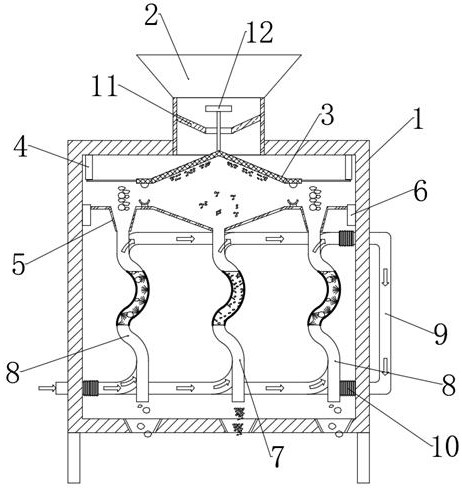

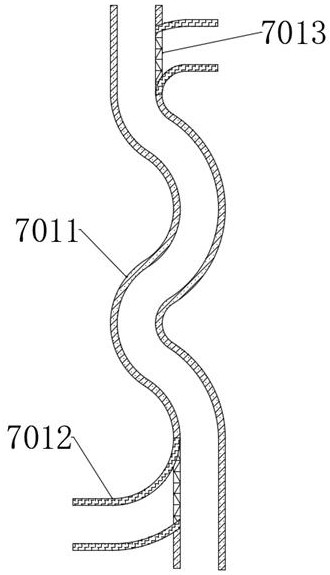

[0047] see Figure 1-10 , a high-efficiency and energy-saving straw powder drying device, please refer to figure 1 , 2 , comprising a drying box 1, the upper end of the drying box 1 is connected with a feeding hopper 2, the inner wall of the feeding hopper 2 is fixedly connected with a control hopper 11, and the middle part of the control hopper 11 is provided with a feeding port, and the upper end of the middle part of the screen one 3 A blocking plate 12 matching the feed inlet is fixedly connected through the connecting rod. When the screen one 3 moves down to the lowest point, the blocking plate 12 just blocks the feed inlet of the control hopper 11, which can effectively control the feeding. material speed, to prevent clogging, there is a screen one 3 above the drying box 1, the screen one 3 is an inverted V-shaped structure, and both sides of the screen one 3 are fixedly connected with horizontal buffer filter plates, This can effectively slow down the blanking speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com