Preparation method of barium titanate/silver iodate heterojunction photocatalyst

A photocatalyst and heterojunction technology, applied in the field of photocatalysis, can solve the problems of low separation rate of photogenerated carriers, low spectral response range, poor photocatalytic performance, etc., and achieve high reducing ability and oxidizing ability, efficient photodegradation Organic pollutants, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

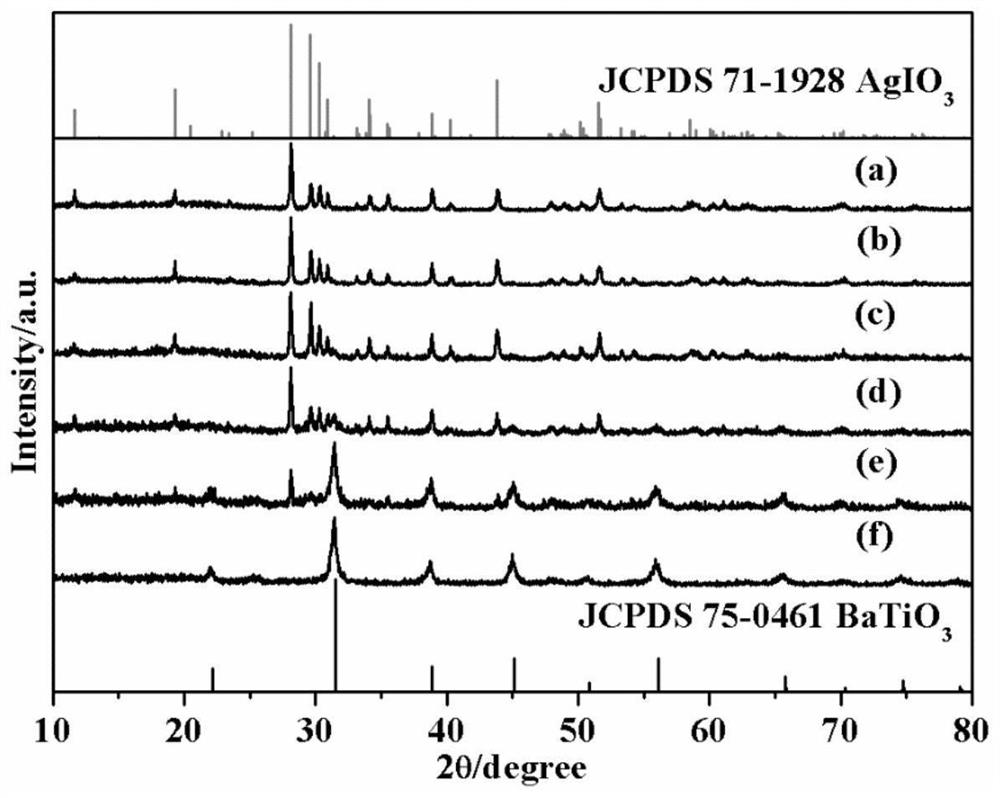

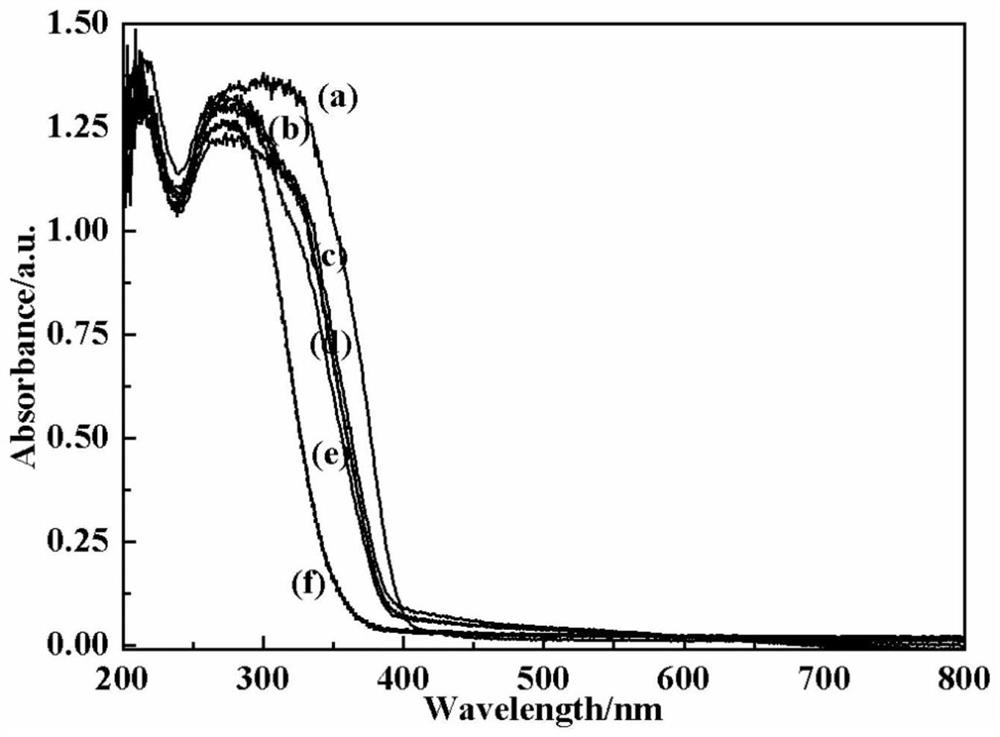

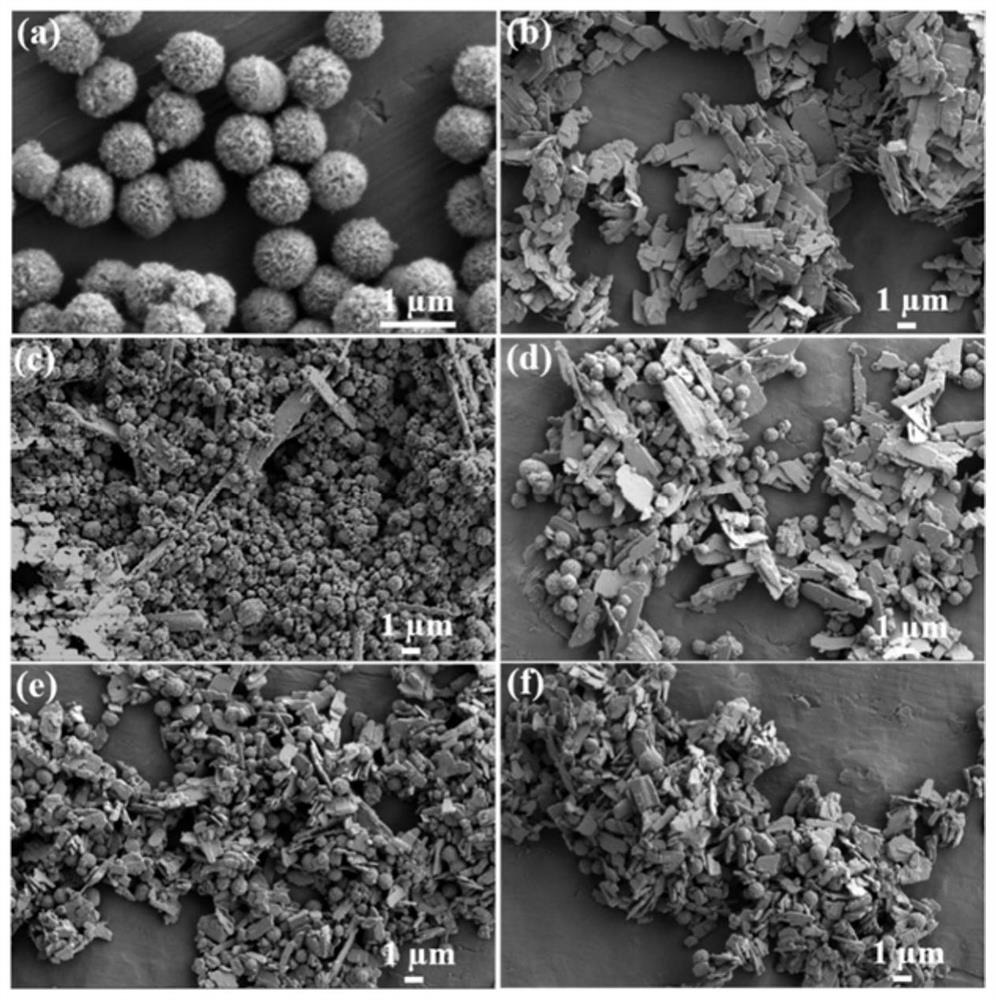

[0032] a BaTiO 3 / AgIO 3 A method for preparing a heterogeneous photocatalyst, comprising the following steps:

[0033] Step 1: Preparation of BaTiO 3 : Add 18.3ml of N,N-dimethylacetamide (DMAC) to 58.4mL of isopropanol (IPA) and stir well, then add 2.5ml of tetrabutyl titanate (TBOT) into the above mixture and stir well , and then transfer the obtained suspension to a 100ml hydrothermal kettle, place the hydrothermal kettle in an oven at 200°C for 20 hours, separate the suspension after the reaction, wash with absolute ethanol, and finally place it in an oven at 60°C Dried to H 2 Ti 2 o 5 Precursor;

[0034] Pour 7ml of water into 28ml of absolute ethanol, and stir for 10min with magnetic force. Add 0.2g of H 2 Ti 2 o 5 Precursor, 0.3g of NaOH and 0.32g of Ba(OH) 2 ·8H 2 O was added to the above solution in turn and stirred evenly, and then placed in a hydrothermal kettle to react at 140°C for 8 hours. After the reaction was completed, the precipitate was washed ...

Embodiment 1

[0056] Preparation of x-AgIO by Solvothermal, Hydrothermal and Room Temperature Precipitation 3 / BaTiO 3 , where x=0.3, x is AgNO 3 with BaTiO 3 The mol ratio, concrete steps are as follows:

[0057] Step 1: Preparation of BaTiO 3 : Add 18.3ml of N,N-dimethylacetamide (DMAC) to 58.4mL of isopropanol (IPA) and stir well, then add 2.5ml of tetrabutyl titanate (TBOT) into the above mixture and stir well , and then transfer the obtained suspension to a 100ml hydrothermal kettle, place the hydrothermal kettle in an oven at 200°C for 20 hours, separate the suspension after the reaction, wash with absolute ethanol, and finally place it in an oven at 60°C Dried to H 2 Ti 2 o 5 Precursor;

[0058] Pour 7ml of water into 28ml of absolute ethanol, and stir for 10min with magnetic force. Add 0.2g of H 2 Ti 2 o 5 Precursor, 0.3g of NaOH and 0.32g of Ba(OH) 2 ·8H 2 O was added to the above solution in turn and stirred evenly, and then placed in a hydrothermal kettle to react a...

Embodiment 2

[0061] Preparation of x-AgIO by Solvothermal, Hydrothermal and Room Temperature Precipitation 3 / BaTiO 3 , where x=1, x is AgNO 3 with BaTiO 3 The mol ratio, concrete steps are as follows:

[0062] Step 1: Preparation of BaTiO 3 : Add 18.3ml of N,N-dimethylacetamide (DMAC) to 58.4mL of isopropanol (IPA) and stir well, then add 2.5ml of tetrabutyl titanate (TBOT) into the above mixture and stir well , and then transfer the obtained suspension to a 100ml hydrothermal kettle, place the hydrothermal kettle in an oven at 200°C for 20 hours, separate the suspension after the reaction, wash with absolute ethanol, and finally place it in an oven at 60°C Dried to H 2 Ti 2 o 5 Precursor;

[0063] Pour 7ml of water into 28ml of absolute ethanol, and stir for 10min with magnetic force. Add 0.2g of H 2 Ti 2 o 5 Precursor, 0.3g of NaOH and 0.32g of Ba(OH) 2 ·8H 2 O was added to the above solution in turn and stirred evenly, and then placed in a hydrothermal kettle to react at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com