High-strength composite fiber expansion anti-cracking agent and preparation process thereof

A technology of composite fiber and anti-cracking agent, which is applied in the field of concrete admixtures to achieve the effect of improving mechanical properties, improving space filling compactness and good expansion fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

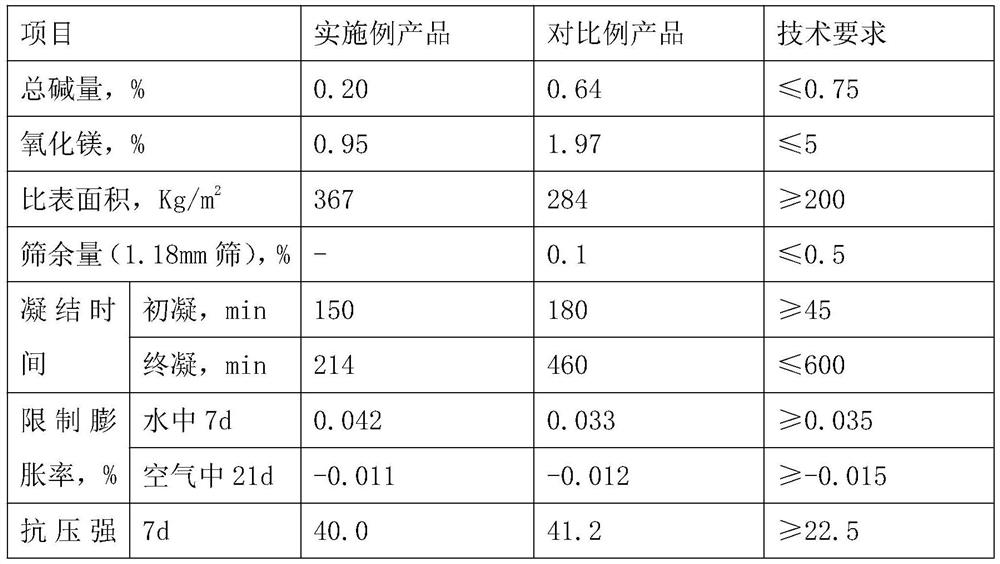

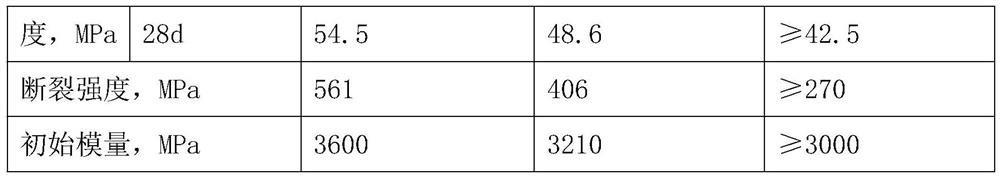

Examples

Embodiment 1

[0025] A high-strength composite fiber expansion anti-cracking agent, including CaO-MgO-Al 2 o 3 -SO 3 Expansion source, fibrous aggregate ore powder, modified fiber doped polymer sol solution, wherein, in terms of mass percentage, CaO-MgO-Al 2 o 3 -SO 3 50% of the expansion source, 25% of the ore powder of the fibrous aggregate, and 20% of the modified fiber doped polymer sol.

[0026] Further, 5% of dispersant is also included, and the dispersant is composed of hydroxypropyl methylcellulose and calcium fluorophosphate with a mass ratio of 1:0.2.

[0027] Among them, the ore powder of fibrous aggregates includes activated gypsum powder and wollastonite powder, the mass ratio of the two is 1:0.5, passed through a 800-mesh sieve, and the sieve residue is less than 5%. The preparation method of activated gypsum powder is as follows:

[0028] Take gypsum powder and grind it to pass through a 400 mesh sieve, then add citric acid to it, the amount of citric acid added is 5.3w...

Embodiment 2

[0035] A high-strength composite fiber expansion anti-cracking agent, including CaO-MgO-Al 2 o 3 -SO 3 Expansion source, fibrous aggregate ore powder, modified fiber doped polymer sol solution, wherein, in terms of mass percentage, CaO-MgO-Al 2 o 3 -SO 3 Expansion source 48%, fibrous aggregate ore powder 28%, modified fiber doped polymer sol 18%.

[0036] Further, 6% of dispersant is also included, and the dispersant is composed of hydroxypropyl methylcellulose and calcium fluorophosphate with a mass ratio of 1:0.1.

[0037] Among them, the ore powder of fibrous aggregates includes activated gypsum powder and wollastonite powder, the mass ratio of the two is 1:0.5, passed through a 800-mesh sieve, and the sieve residue is less than 5%. The preparation method of activated gypsum powder is as follows:

[0038] Take the gypsum powder and grind it to pass through a 400 mesh sieve, then add citric acid to it, the amount of citric acid added is 5.4wt% of the mass of the gypsum...

Embodiment 3

[0045] A high-strength composite fiber expansion anti-cracking agent, including CaO-MgO-Al 2 o 3 -SO 3 Expansion source, fibrous aggregate ore powder, modified fiber doped polymer sol solution, wherein, in terms of mass percentage, CaO-MgO-Al 2 o 3 -SO 3 Expansion source 45%, fibrous aggregate ore powder 25%, modified fiber doped polymer sol 22%.

[0046] Further, 8% of dispersant is also included, and the dispersant is composed of hydroxypropyl methylcellulose and calcium fluorophosphate with a mass ratio of 1:0.5.

[0047] Among them, the ore powder of fibrous aggregates includes activated gypsum powder and wollastonite powder, the mass ratio of the two is 1:0.5, passed through a 800-mesh sieve, and the sieve residue is less than 5%. The preparation method of activated gypsum powder is as follows:

[0048] Take gypsum powder and grind it to pass through a 400 mesh sieve, then add citric acid to it, the amount of citric acid added is 4.2wt% of the mass of gypsum powder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com