Anionic acrylamide polymer, calcium chloride weighted fracturing fluid containing anionic acrylamide polymer, and preparation methods of anionic acrylamide polymer and calcium chloride weighted fracturing fluid

A technology of acrylamide and acrylamide monomers, applied in chemical instruments and methods, separation/purification of carboxylic acid amides, compositions of drilling holes, etc., can solve problems such as reducing construction pressure and achieve good temperature resistance and shear resistance. Performance, stable performance, and complete glue breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

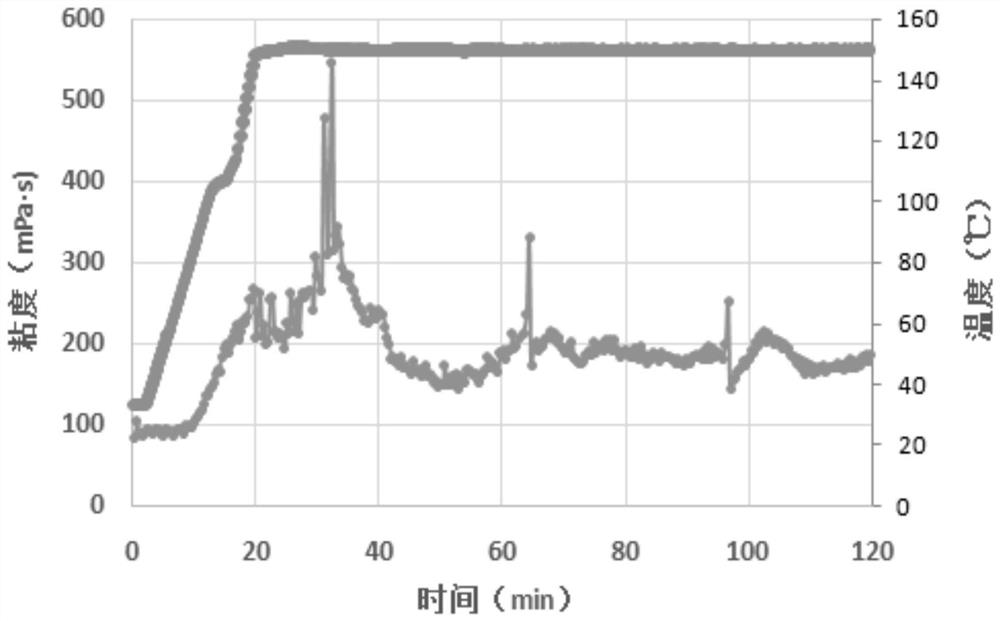

Embodiment 1

[0049] This embodiment provides a high-concentration divalent salt-resistant, high-temperature-resistant polymer and its production process. The preparation process includes the following processes:

[0050] (1) Preparation process of acrylamide monomer

[0051] According to the technological process of microbial acrylamide, firstly, special microbial bacteria are cultivated in three-stage amplification, and the fermentation liquid with sufficient number of bacteria is cultivated through the strain bottle, seed tank and fermentation tank, and then transferred to the hydration catalytic reaction kettle and then added with acrylonitrile , so that bacteria can metabolize acrylonitrile to produce acrylamide. The acrylamide aqueous solution produced later has other impurities such as residual bacteria and residual acrylonitrile, so it needs to be refined by membrane filtration and ion exchange columns. The final acrylamide aqueous solution is the main raw material for the synthesis...

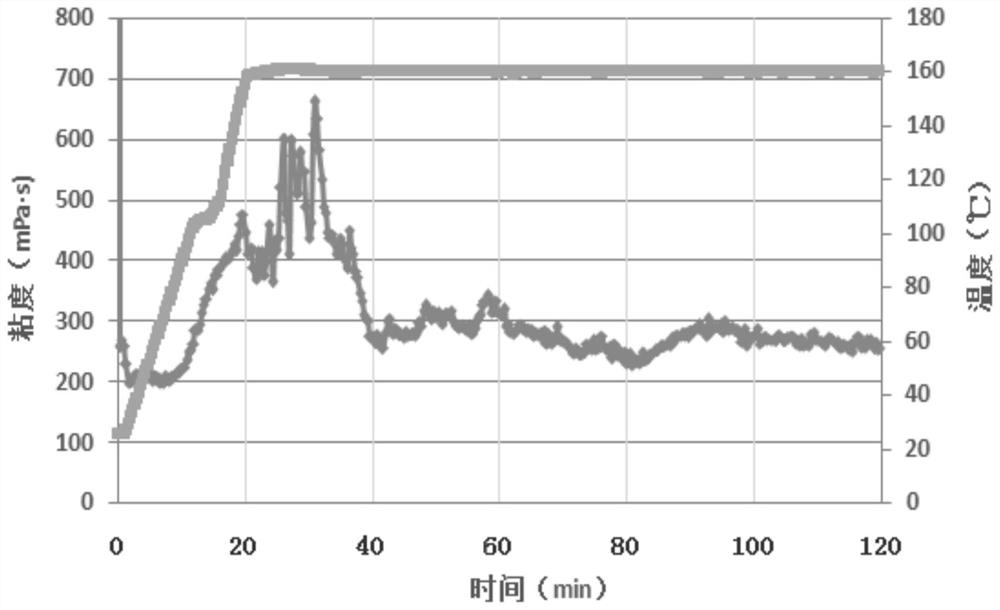

Embodiment 2

[0061] This embodiment provides a high-concentration divalent salt-resistant, high-temperature-resistant polymer and its production process. The preparation process includes the following processes:

[0062] (1) Preparation process of acrylamide monomer

[0063] According to the technological process of microbial acrylamide, firstly, special microbial bacteria are cultivated in three-stage amplification, and the fermentation liquid with sufficient number of bacteria is cultivated through the strain bottle, seed tank and fermentation tank, and then transferred to the hydration catalytic reaction kettle and then added with acrylonitrile , so that bacteria can metabolize acrylonitrile to produce acrylamide. The acrylamide aqueous solution produced later has other impurities such as residual bacteria and residual acrylonitrile, so it needs to be refined by membrane filtration and ion exchange columns. The final acrylamide aqueous solution is the main raw material for the synthesis...

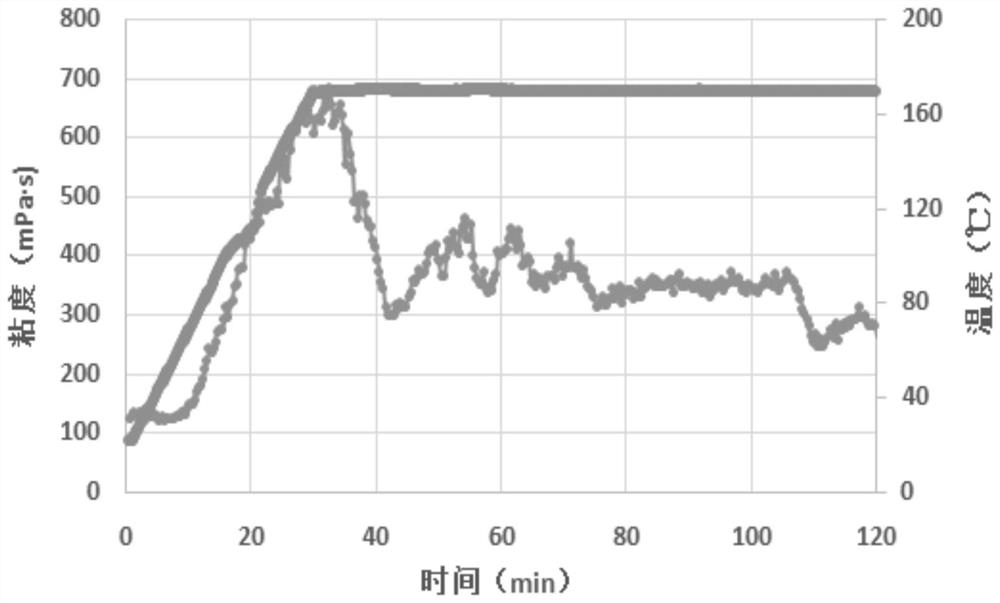

Embodiment 3

[0073] This embodiment provides a high-concentration divalent salt-resistant, high-temperature-resistant polymer and its production process. The preparation process includes the following processes:

[0074] (1) Preparation process of acrylamide monomer

[0075] According to the technological process of microbial acrylamide, firstly, special microbial bacteria are cultivated in three-stage amplification, and the fermentation liquid with sufficient number of bacteria is cultivated through the strain bottle, seed tank and fermentation tank, and then transferred to the hydration catalytic reaction kettle and then added with acrylonitrile , so that bacteria can metabolize acrylonitrile to produce acrylamide. The acrylamide aqueous solution produced later has other impurities such as residual bacteria and residual acrylonitrile, so it needs to be refined by membrane filtration and ion exchange columns. The final acrylamide aqueous solution is the main raw material for the synthesis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com