Separator for low temp. type fuel cell and method of production thereof

A fuel cell and separator technology, which is applied in the direction of fuel cells, fuel cell parts, battery pack parts, etc. It can solve the problems of poor acid resistance of organic membranes, increased contact resistance, peeling or dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A stainless steel plate having the composition shown in Table 1 was used as the stainless steel substrate S. Carbon black with an average size of 0.05 μm and graphite particles with an average size of 3 μm were used as carbon particles.

[0074] steel

type

Components other than iron (weight%)

C

Si

mn

Ni

Cr

Mo

Cu

N

A

0.05

0.57

0.91

8.9

18.5

-

-

-

B

0.02

0.48

0.55

25.3

24.5

5.1

0.52

0.15

C

0.01

0.83

0.66

6.1

24.8

3.0

0.45

0.13

Steel A: Austenitic stainless steel

Steel B: Austenitic stainless steel

Steel C: Austenitic-ferrite duplex stainless steel

[0075] Coat carbon black or graphite particles to a bond rate of 5 mg / m by wiping a stainless steel plate with a felt impregnated with carbon black o...

Embodiment 2

[0087] In Example 2, the stainless steel plates shown in Table 1 were used as substrates. A nickel-chromium plating layer dispersed with carbon particles was formed on the surface of each stainless steel substrate by vapor deposition coating or electroplating described below.

[0088] Method 1: Form nickel-chromium coating by vapor deposition coating method

[0089] Graphite particles with an average size of 2 µm and carbon black with an average size of 0.03 µm were used as carbon particles. After activating the surface of the stainless steel plate in a vacuum chamber, the surface was wiped with a felt impregnated with carbon particles so that at 3 g / m 2 ~15g / m 2 The adhesion ratio applies carbon particles to the stainless steel surface. Subsequently, nickel and chromium were sputtered simultaneously in the same vacuum chamber at a deposition rate of 0.005 μm / sec.

[0090] The nickel-chromium plating layer PL formed in this way had a thickness of 0.5 µm and a chromium cont...

Embodiment 3

[0097] A stainless steel plate shown in Table 1 was used as a substrate, and a carbon particle-dispersed coating was formed on the stainless steel substrate by vacuum deposition.

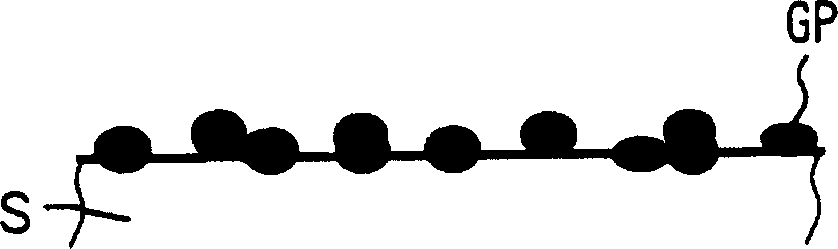

[0098] Graphite particles with an average size of 2 µm and carbon black with an average size of 0.03 µm were used as carbon particles. After activating the surface of each stainless steel plate in a vacuum chamber, the surface was wiped with a felt impregnated with carbon particles so that at 5 g / m 2 ~15g / m 2 A binding ratio of carbon particles was applied to the surface of the stainless steel substrate. Subsequently, one or both of tantalum and titanium were sputtered simultaneously in the same vacuum chamber at a deposition rate of 0.004 μm / sec. The thickness of the plated layer PL formed in this way was 0.5 μm. like Figure 4A and Figure 4B As shown, graphite particles GP or carbon black aggregates CA are dispersed in each coating PL, respectively.

[0099] The contact resistance and acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com