Preparation method of camellia fibers

A camellia and fiber technology, applied in the dyeing method, removing liquid/gas/steam with squeeze rollers, treating textile material carriers, etc., can solve the problems of high price and achieve the goals of increasing adhesion, reducing quantity, and increasing the amount of addition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

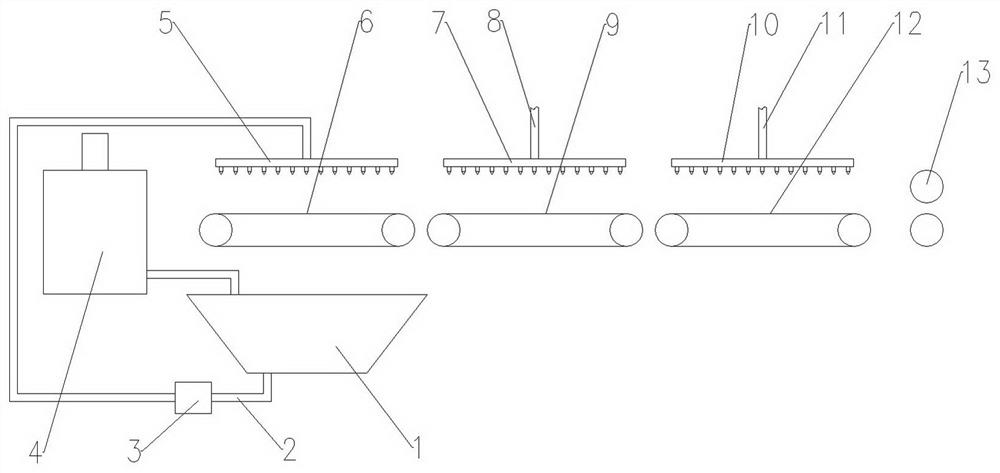

[0036] Example: as attached figure 1 Shown, a kind of preparation method of camellia fiber, described preparation method comprises the following steps:

[0037] (1) Preparation of camellia extract solution

[0038] Put the camellia extract powder in deionized water at 50°C, add dispersant and reactive dyes, stir with an electric mixer for 1 hour, let it stand for precipitation, take the supernatant, filter twice with a 200-mesh filter, and extract the camellia in the resulting mixed solution The solid content is 10%.

[0039] (2) Pengrun treatment of cationic viscose fiber

[0040] Wet the cationic viscose fiber with deionized water, spray it evenly on the surface of the fiber with a sprayer, and the temperature is 30°C to make the fiber absorb water evenly and expand the fiber. (3) Addition of camellia extract mixed solution

[0041] The cationic viscose fiber is loosened by an opener, and the viscose fiber after opening is placed on the first chain net 6 which rotates ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com