Device and method for testing combustion characteristics of material in low-pressure oxygen-enriched environment

A technology for combustion characteristics and testing devices, applied in measurement devices, chemical analysis using combustion, instruments, etc., can solve problems such as inability to accurately judge the risk of combustion products of materials, errors in flue gas measurement parameters, and complicated operations. Build, collect accurately, reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides a technical solution:

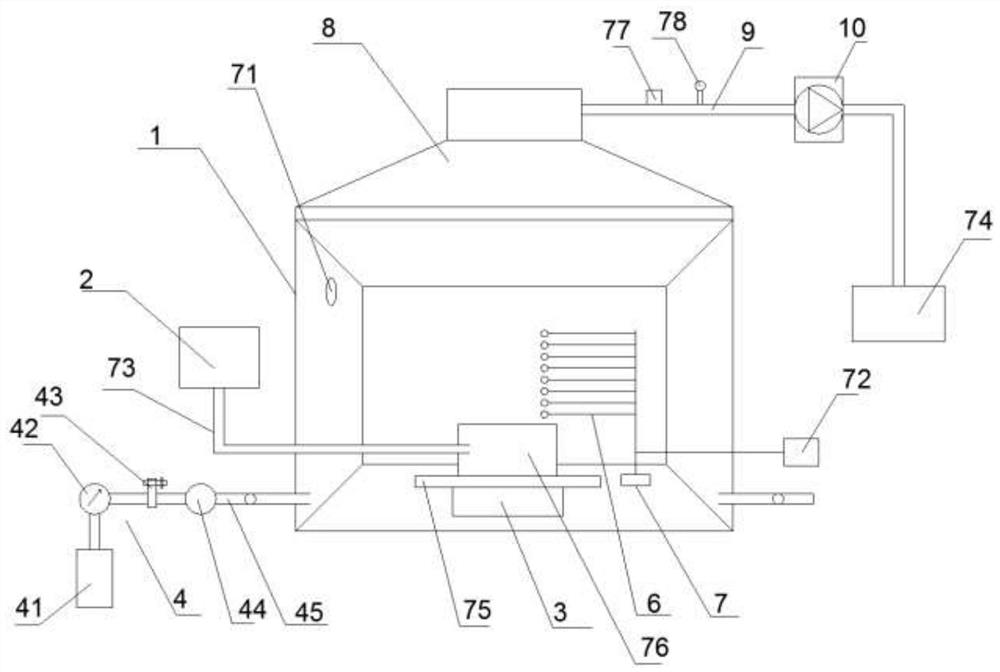

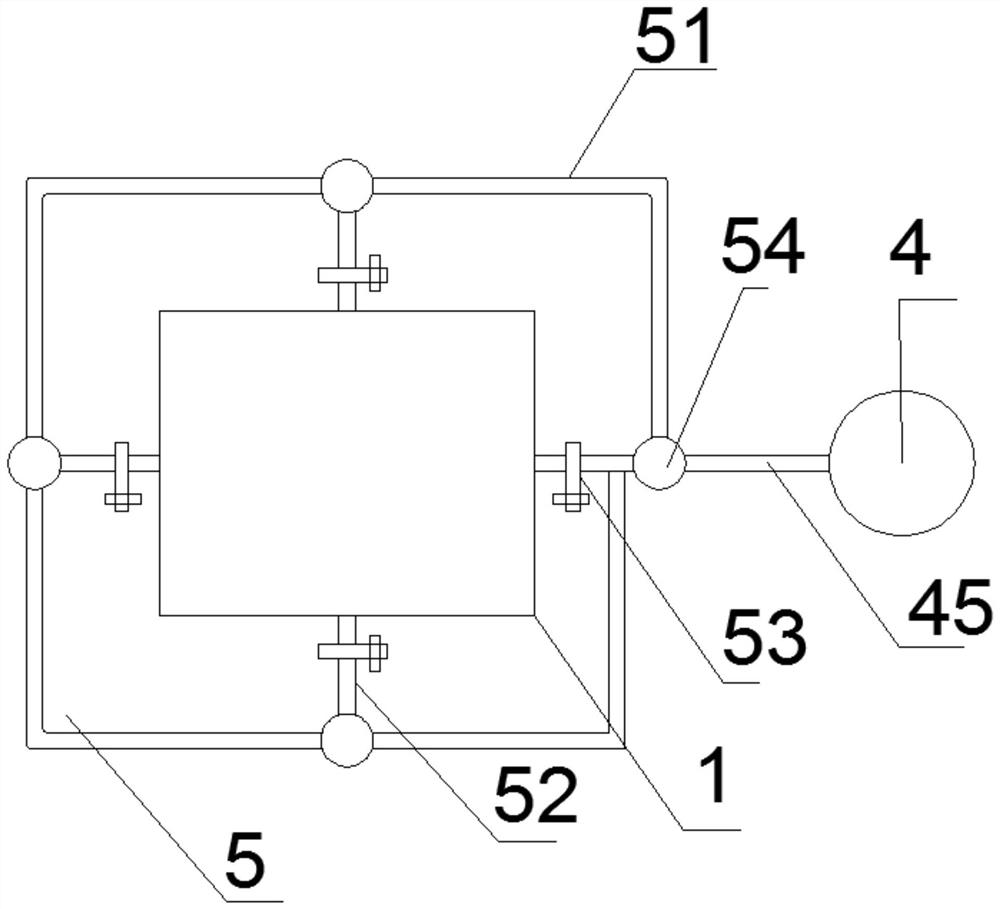

[0040] Please refer to Figure 1~2 As shown, a device for testing the combustion characteristics of materials in a low-pressure oxygen-enriched environment includes a low-pressure cabin 1, an ignition device 2, a weighing device 3, an oxygenation system 4, an exhaust system, a closed-loop pressure control system 5 and an online flue gas Detection and analysis system; the closed-loop pressure control system 5 is annularly set at the bottom of the low-pressure cabin 1, the closed-loop pressure control system 5 is connected to the oxygenation system 4, and the low-pressure cabin 1 is respectively connected to the closed-loop pressure control system 5 Connect with the exhaust system, carry out oxygen input to the low-pressure cabin body 1 through the closed-loop pressure control system 5, discharge the gas of the low-pressure cabin body 1 through the exhaust system, and ensure the constant pressure in the low-pressure cabin bod...

Embodiment 2

[0066] Based on the above-mentioned embodiment 1, this scheme provides a method for testing the combustion characteristics of materials in a low-pressure oxygen-enriched environment:

[0067] Step 1: drying the target material 76;

[0068] Step 2: Place the dried target material 76 in step 1 on the device with the function of measuring quality, and vacuumize the specified holding space, then fill it with oxygen, and turn on the exhaust function at the same time, so that the holding space The pressure in the space reaches the required steady state;

[0069] Step 3: use the ignition device to ignite the target material 76 in a closed manner in the carrying space, and measure the burning time of the target material 76;

[0070] Step 4: Record the change of the burning weight of the target material 76, and record the weight loss curve, calculate the loss rate of the burning mass of the material, detect the temperature of the flame flue gas at different heights, and monitor the ch...

Embodiment 3

[0074] Based on the above-mentioned embodiment 2, this solution provides a method for testing the combustion characteristics of materials in a low-pressure oxygen-enriched environment: specifically, a carton is used as the target material 76 for the experiment; the specific experimental steps are as follows:

[0075] Step 1: Before the experiment, prepare the sample carton, and then place the sample in a dry room for at least 24 hours to remove moisture;

[0076] Step 2: When starting the experiment, place the dried carton on the tray 75 on the balance, turn on the vacuum pump, evacuate the cabin, then adjust the oxygen concentration, adjust the pressure of the external oxygen cylinder to 0.25-0.4MPa, and turn on the instrument. The oxygen regulator control valve is adjusted to 0.2MPa, and the total flow rate is set to 10L / min;

[0077] Step 3: Adjust the pressure in the low-pressure chamber. When the pressure reaches a stable state, power on the KHGYD-24V portable DC plasma i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com