Radioactive organic extractant waste liquid treatment method and device

An organic extractant and waste liquid treatment technology, applied in radioactive purification, separation methods, organic chemistry, etc., can solve the problems of poor effect of heavy radiolysis products, increased operating costs, waste of resources, etc., to reduce the final disposal volume, The effect of saving operating costs and saving disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

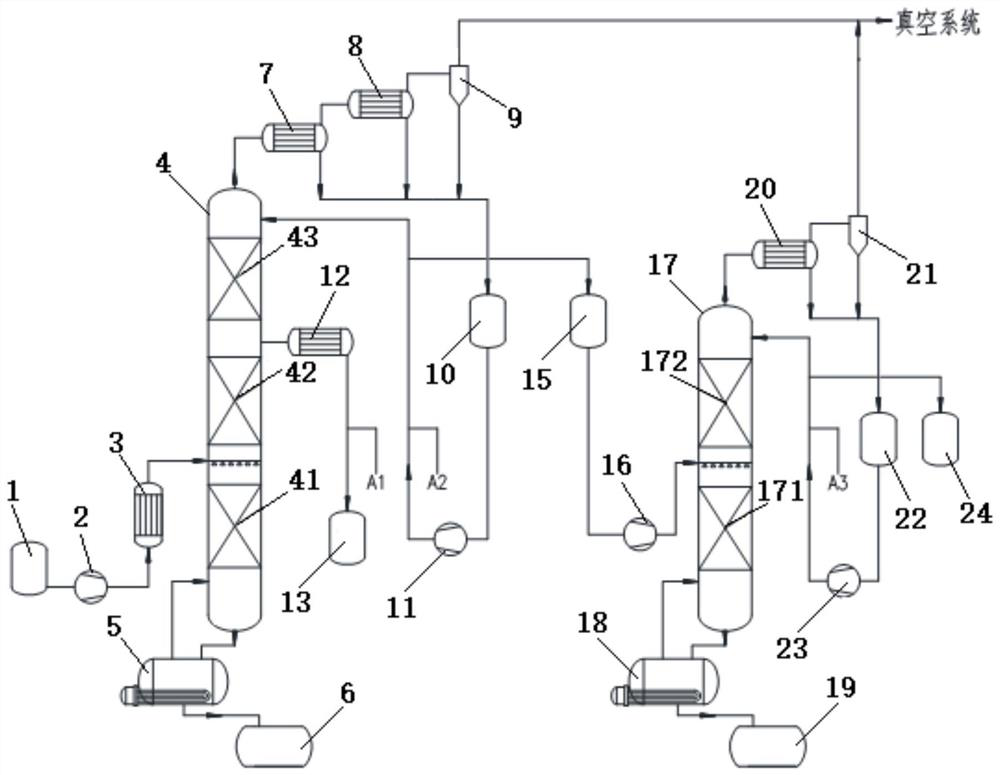

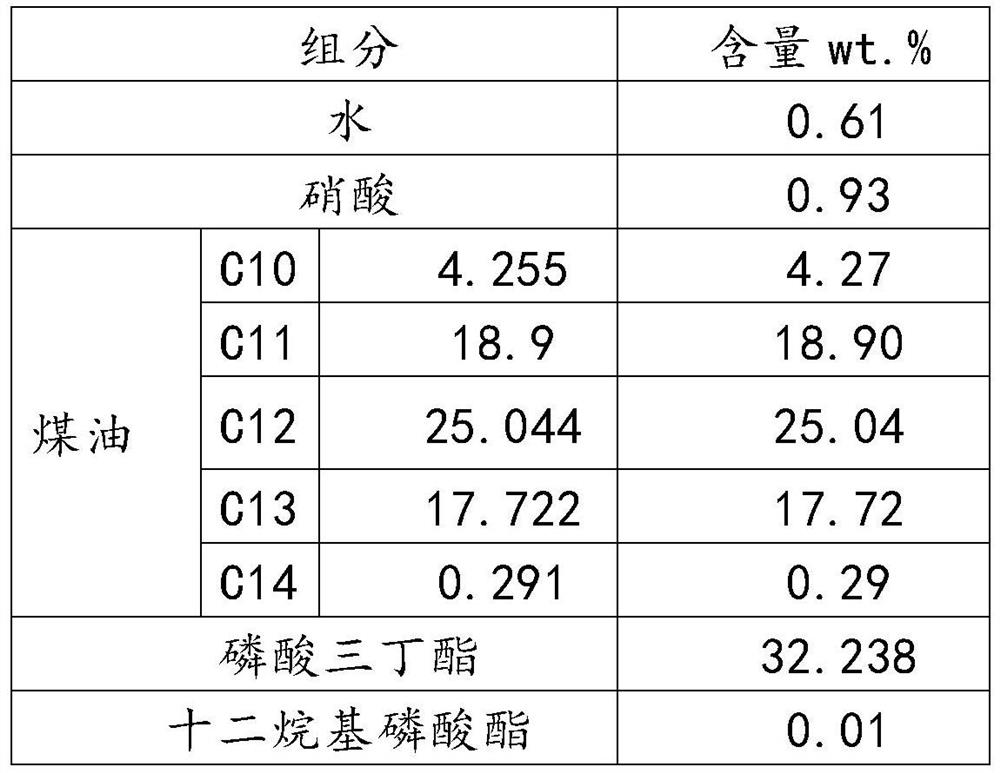

[0047] Such as figure 1 As shown, the present embodiment discloses a method for treating radioactive organic extractant waste liquid, the organic extractant is tributyl phosphate (TBP) / kerosene (OK), treated

[0048] Reasonable methods include:

[0049] The radioactive organic waste liquid is rectified, and the nuclides (such as Y-90, Sr-90, Ni-63, Pu-239, U-235, etc.) and heavy radiolysis products (such as dodecyl Phosphate), to obtain the first mixture and tributyl phosphate (TBP), and then separate the light radiolysis products (such as nitrates, nitrites, hydroxamic acid, etc.) in the first mixture to obtain kerosene (OK) .

[0050] This embodiment also discloses a system for treating radioactive organic extractant waste liquid, including a primary rectification unit and a secondary rectification unit, wherein:

[0051] The primary rectification unit is used to separate nuclides and heavy radiolysis products in the radioactive organic extractant waste liquid to obtain t...

Embodiment 2

[0055] This embodiment discloses a method for the treatment of radioactive organic extractant waste liquid, such as figure 1 shown, including:

[0056] S101, the radioactive organic extractant waste liquid is input to the first rectification tower 4 for primary rectification treatment, and the nuclide and heavy radiolysis products are separated to obtain the first mixture and TBP, wherein, the radioactive organic extractant is The waste liquid is input into the first rectification tower 4 for primary rectification treatment, so that the radioactive organic extractant waste liquid is heated and evaporated in the tower kettle reboiler of the first rectification tower 4, so that the radioactive organic extractant waste liquid The radiolysis nuclides and heavy radiolysis products in the first rectification tower 4 are retained in the tower still reboiler of the first rectification tower 4, and the first organic vapor produced by evaporation is processed by the first rectification ...

Embodiment 3

[0071] Such as figure 1 As shown, this embodiment discloses a system for the treatment of radioactive organic extractant waste liquid, including a primary rectification unit and a secondary rectification unit, wherein: the primary rectification unit is used to separate the radioactive organic extractant waste liquid Nuclides and heavy radiolysis products of the first mixture and TBP are obtained; the secondary rectification unit is connected with the primary rectification unit for receiving the first mixture and separating the light radiolysis products in the first mixture, Get kerosene.

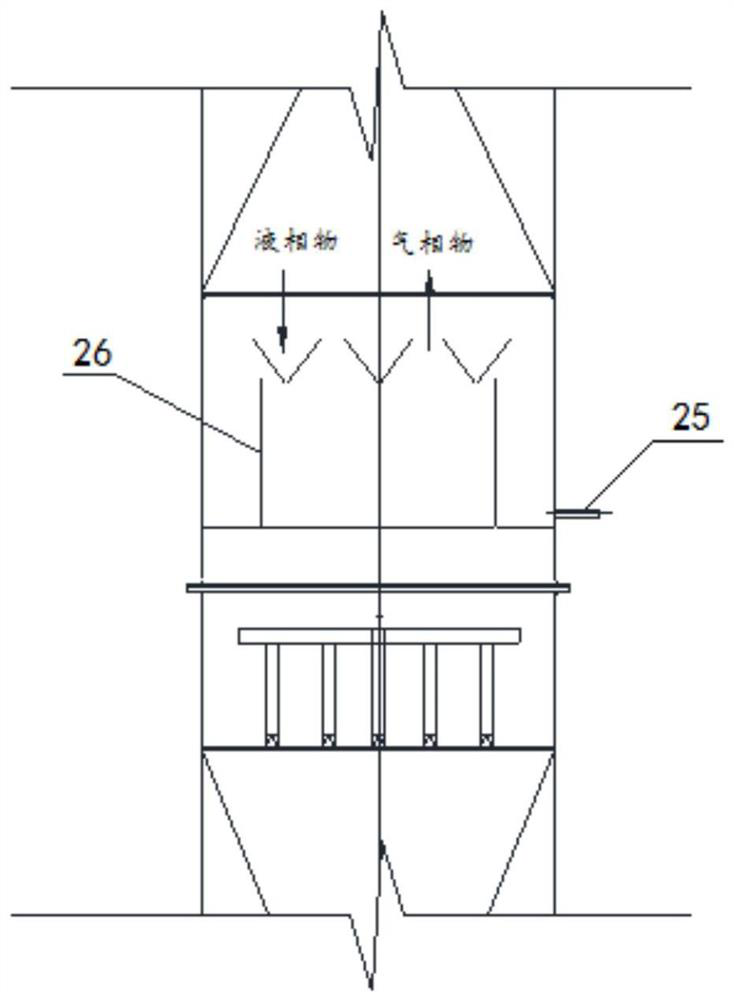

[0072] In this embodiment, the primary rectification unit includes a first rectification column 4, a first reboiler 5, a first condensation mechanism, and a first reflux tank 10, wherein:

[0073] The first rectifying tower 4 is provided with feed inlet, to pass into radioactive organic extractant waste liquid; The first reboiler 5 links to each other with the first rectifying tower 4, is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com