Beverage composition

A composition, beverage technology, applied in food science, tea extraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] 1. Analysis of non-polymeric catechins

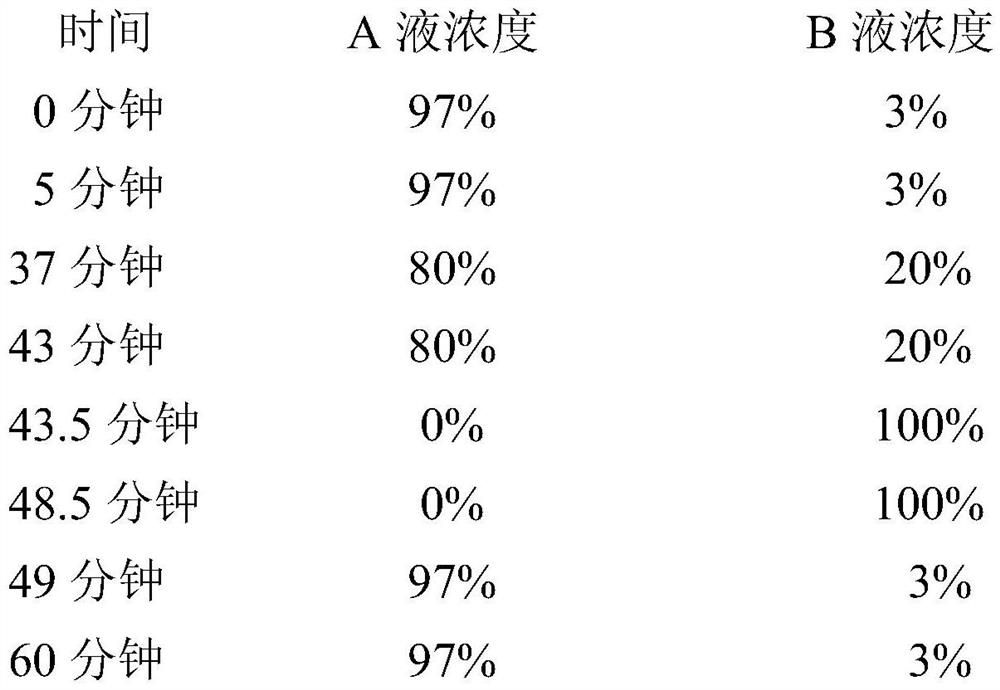

[0049] After dissolving and diluting the sample with pure water, using a high-performance liquid chromatograph (model SCL-10AVP, manufactured by Shimadzu Corporation), a packed column for liquid chromatography (L-Column ODS, 4.6 mmφ×250 mm particle size 5 μm: manufactured by Chemical Substance Evaluation Research Institute), and measured by a gradient method at a column temperature of 35°C. The mobile phase A liquid is set as a distilled aqueous solution containing 0.1mol / L acetic acid, and the B liquid is set as an acetonitrile solution containing 0.1mol / L acetic acid, and the flow rate is 1mL / min, the sample injection volume is 10μL, and the UV detector wavelength is Under the condition of 280nm. In addition, gradient conditions are as follows.

[0050] Concentration gradient conditions (volume%)

[0051]

[0052]2. Analysis of ethanol

[0053] The analysis of ethanol was carried out according to the gas chromatography s...

manufacture example 1

[0095] Manufacture of tea extract I

[0096] 30 g of sencha leaves (produced in Miyazaki and Kagoshima prefectures) were poured into 2000 g of hot water at 90° C. for 3 minutes for extraction. After removing the tea leaves, the liquid temperature was cooled to 20° C. to obtain tea extract I. The content of non-polymer catechins in the obtained tea extract I was 80 mg / 100 mL. Furthermore, ascarin was not detected.

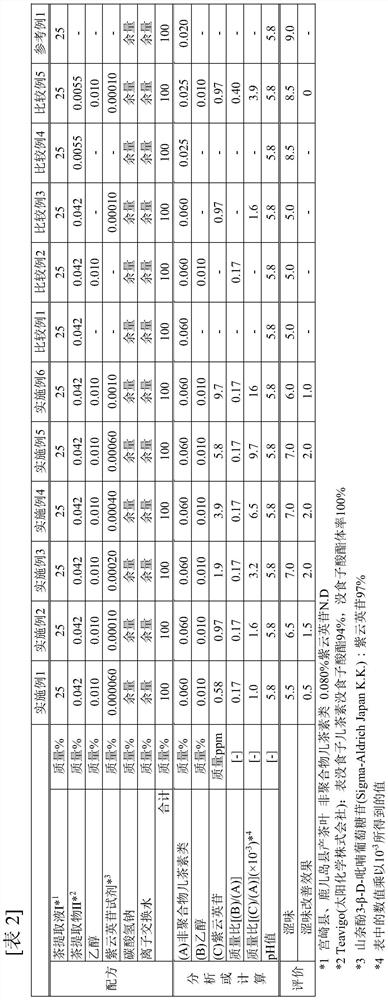

reference example 1

[0098] The tea extract I obtained in Production Example 1 was mixed with ion-exchanged water at the ratio shown in Table 2, then adjusted with sodium bicarbonate so that the pH value became 5.8, and then the total amount was adjusted to 5.8 with ion-exchanged water. Adjusted to 100% by mass to obtain a green tea beverage. Next, the obtained green tea beverage was filled in a PET bottle with a capacity of 200 mL, and heat-sterilized (post-mixing method). The sterilization condition is 30 minutes at 85° C., and the F0 value is 0.0074. Then, the obtained containerized green tea beverage was analyzed. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com