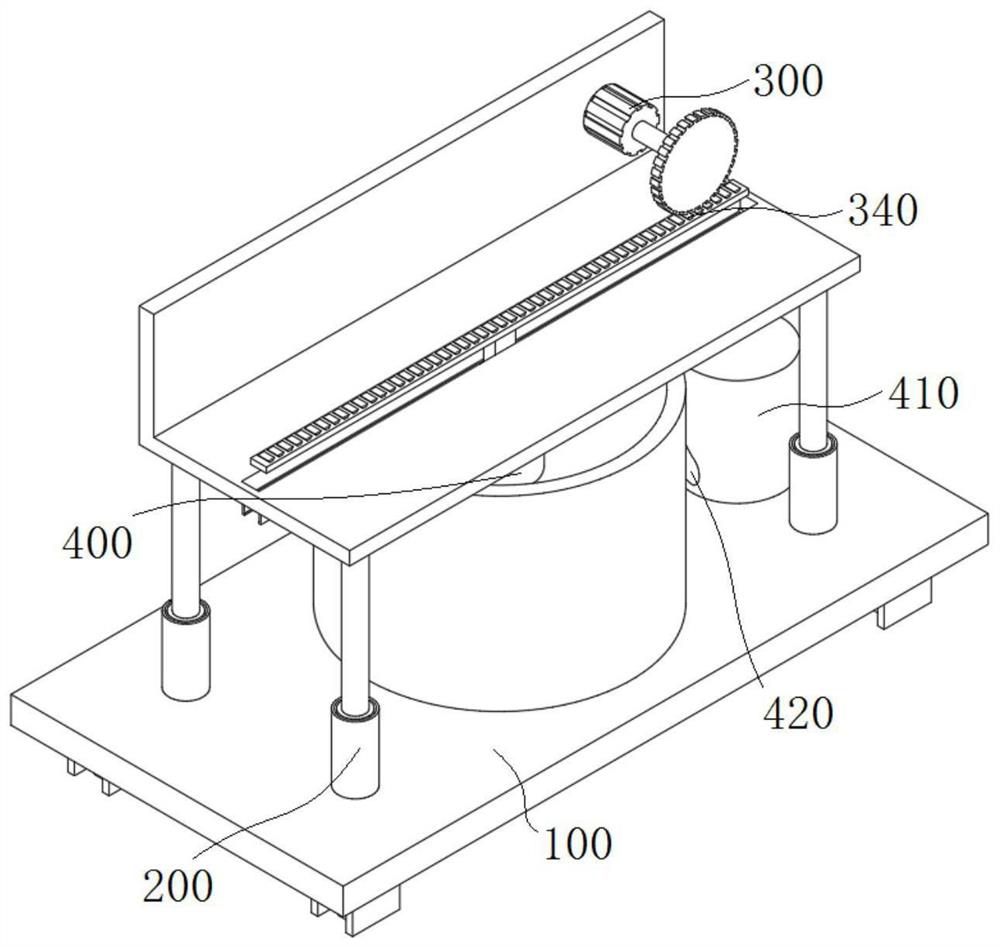

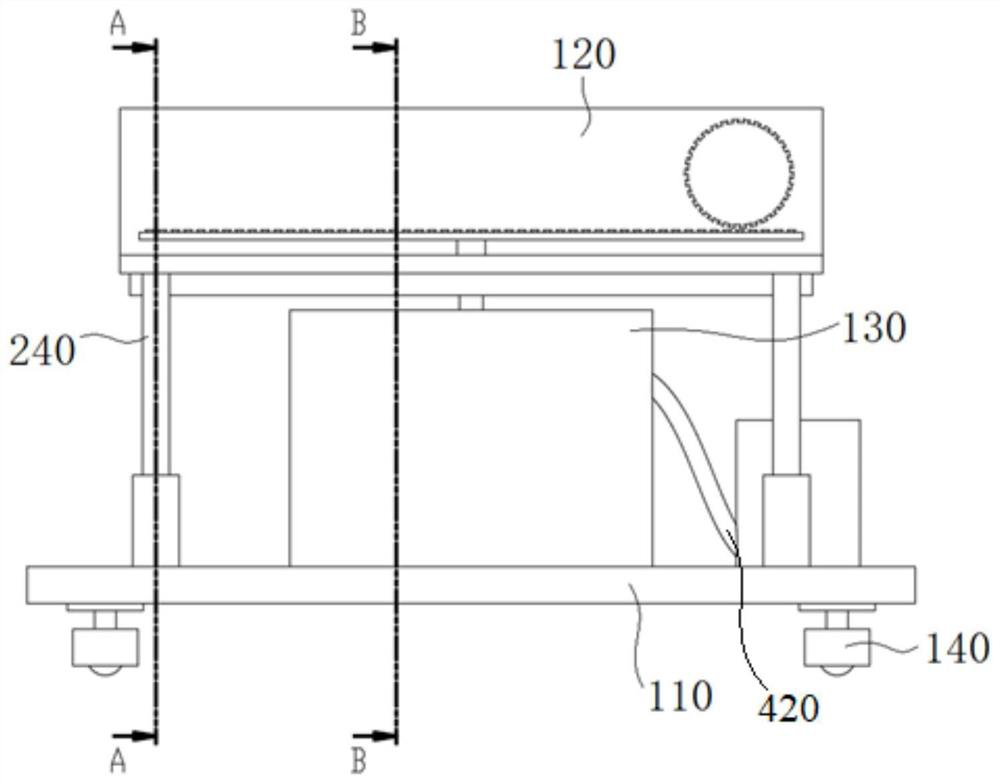

Spray drying device

A technology of drying device and drying barrel, which is applied in the direction of spray evaporation and evaporator accessories, etc., which can solve the problems of inconvenient storage and transportation, poor drying effect, and easy caking, etc., to solve caking, improve drying effect, and facilitate storage and transport effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

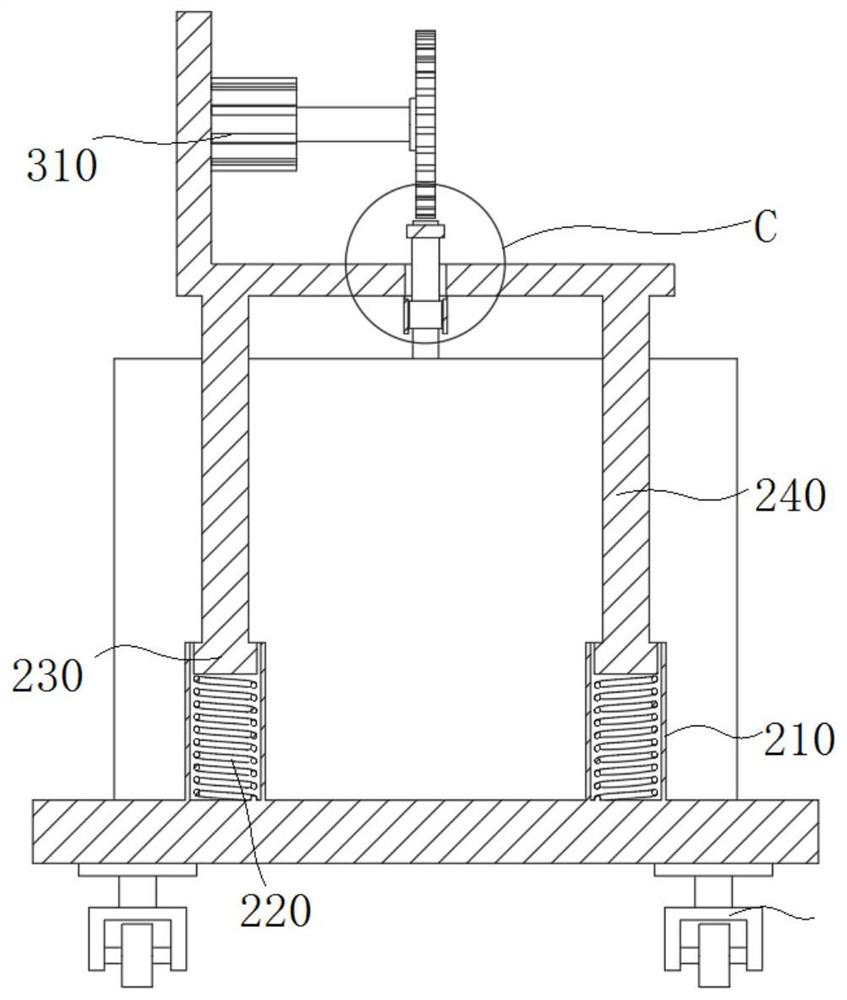

[0029] Among them, such as Figure 4 In the embodiment shown, the mounting plate 120 can be an L-shaped plate, the motor 310 can be installed on the vertical side plate of the mounting plate 120, and the horizontal side plate of the mounting plate 120 is provided with a through hole extending along the length direction of the rack 340. The rack 340 is arranged above the through groove; the transmission structure 300 also includes a slider 360, the slider 360 is connected below the rack 340 through the through groove, and is connected with the spray structure 400 located below, and the spray structure 400 is connected with the slide There are multiple connection methods between the blocks 360 , such as direct fixing by screws. According to an embodiment of the present invention, the spray structure 400 is connected to the sliding block 360 through a connecting column 380 .

[0030] combine Figure 5 , through the above scheme, the lower end of the through groove on the mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com