New energy automobile windscreen wiper nozzle and forming process thereof

A new energy vehicle, molding technology, applied in the direction of injection device, vehicle maintenance, injection device, etc., can solve the problems of easy corrosion, low precision, low processing efficiency, etc., to extend the service life, ensure stability and consistency, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

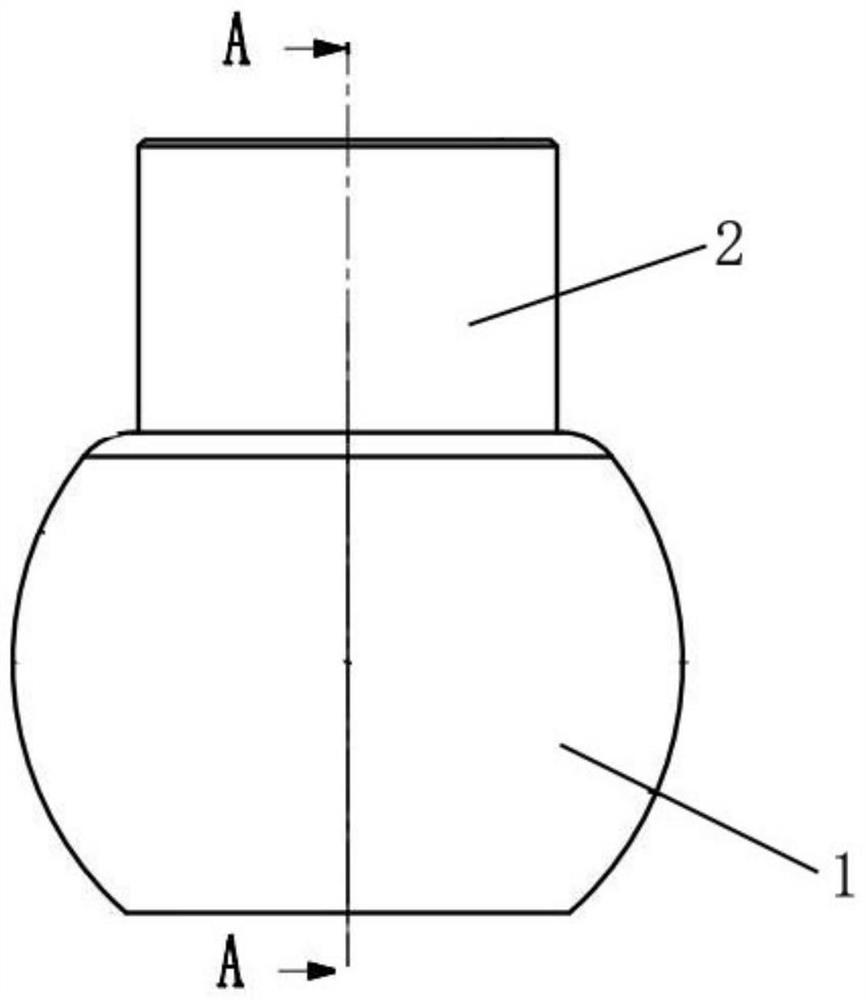

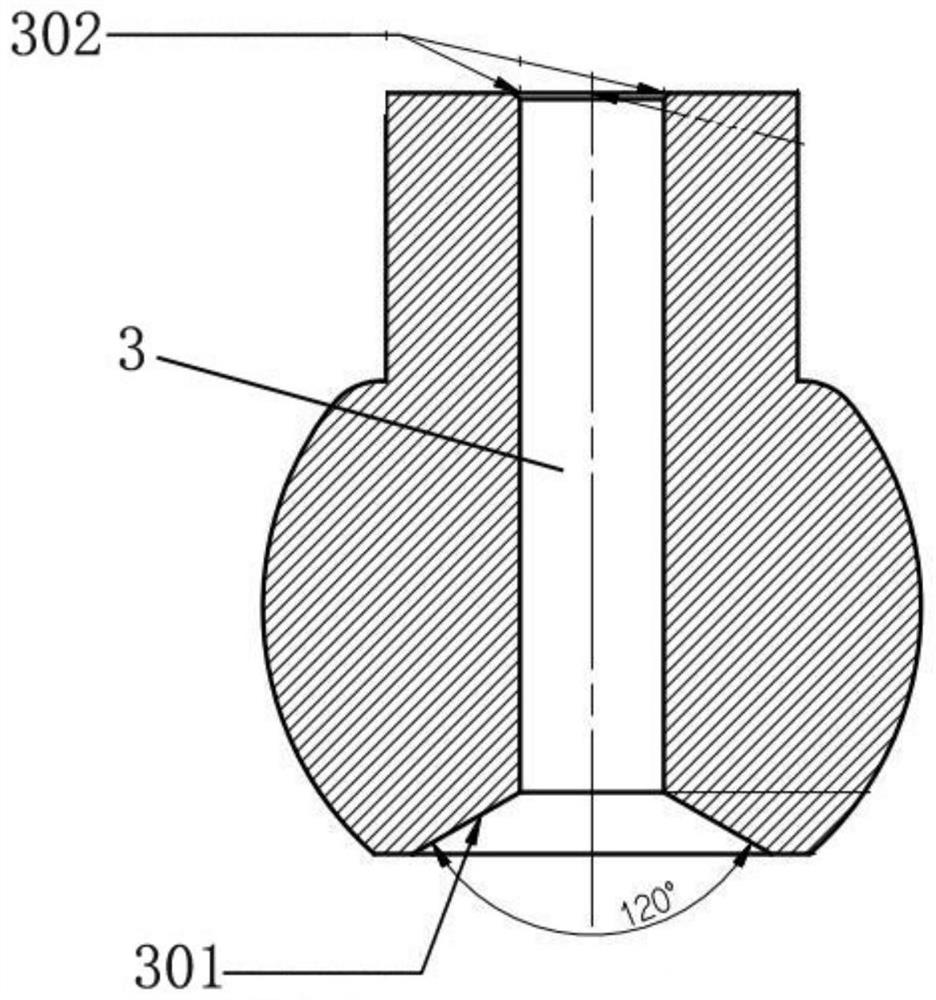

[0026] like figure 1 As shown, the new energy vehicle wiper nozzle includes an integrally formed sphere 1 and a water spray column 2, the sphere 1 and the water spray column 2 run through a water spray tank 3, the water inlet end of the water spray tank 3 is a trumpet-shaped structure 301, and the water spray tank 3 The water outlet end is a chamfered structure 302. The horn-shaped structure 301 has an angle of 120°, and the arrangement of the horn-shaped structure 301 is beneficial for water to enter the water spray column 2 . The chamfer structure 302C is 0.76-0.79mm. When the water pressure is 1par, the water sprayed from the hole can gather, and the outlet of the spray water is at the same angle as the hole wall, realizing precise water spray. The diameter of the sphere 1 is 3.2 mm, the total height of the sphere 1 and the water spray column 2 is 3.7 mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com