Manipulator blowing structure and using method thereof

A technology of manipulators and gas parts, applied in the field of manipulators, can solve problems such as poor adsorption, unclean surface of fixtures, affecting processing accuracy and processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

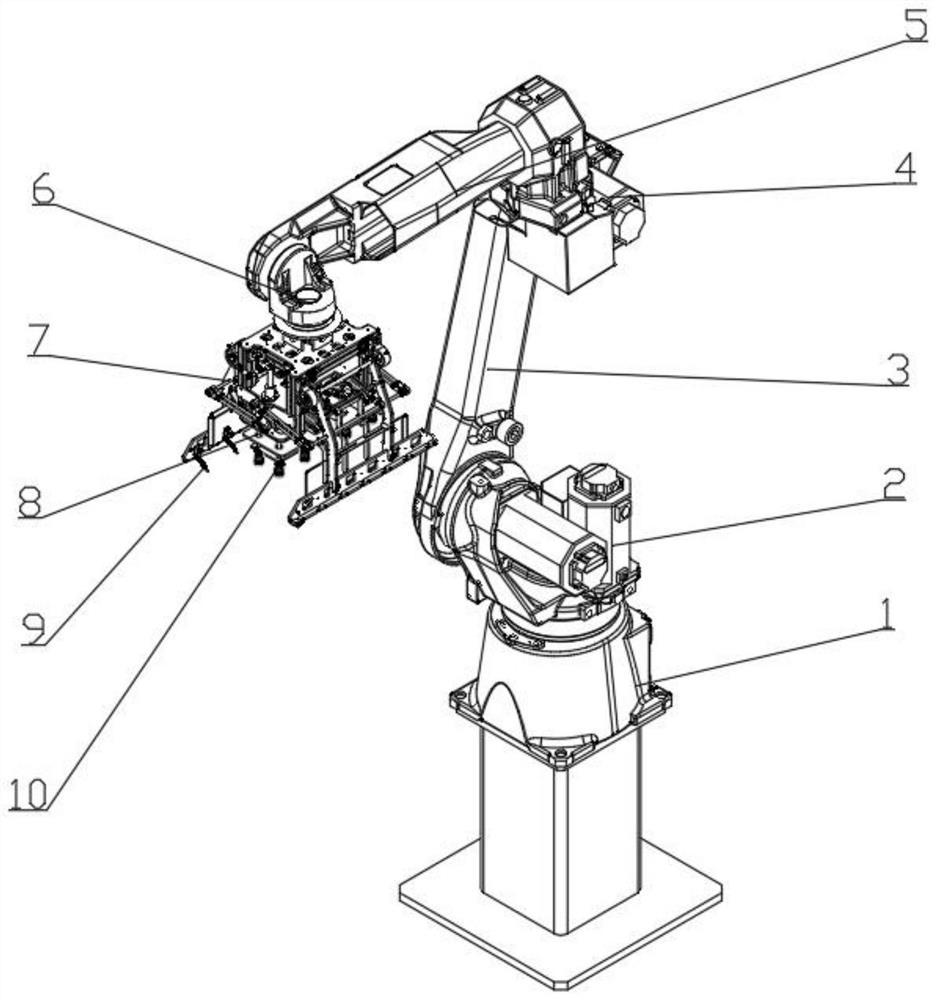

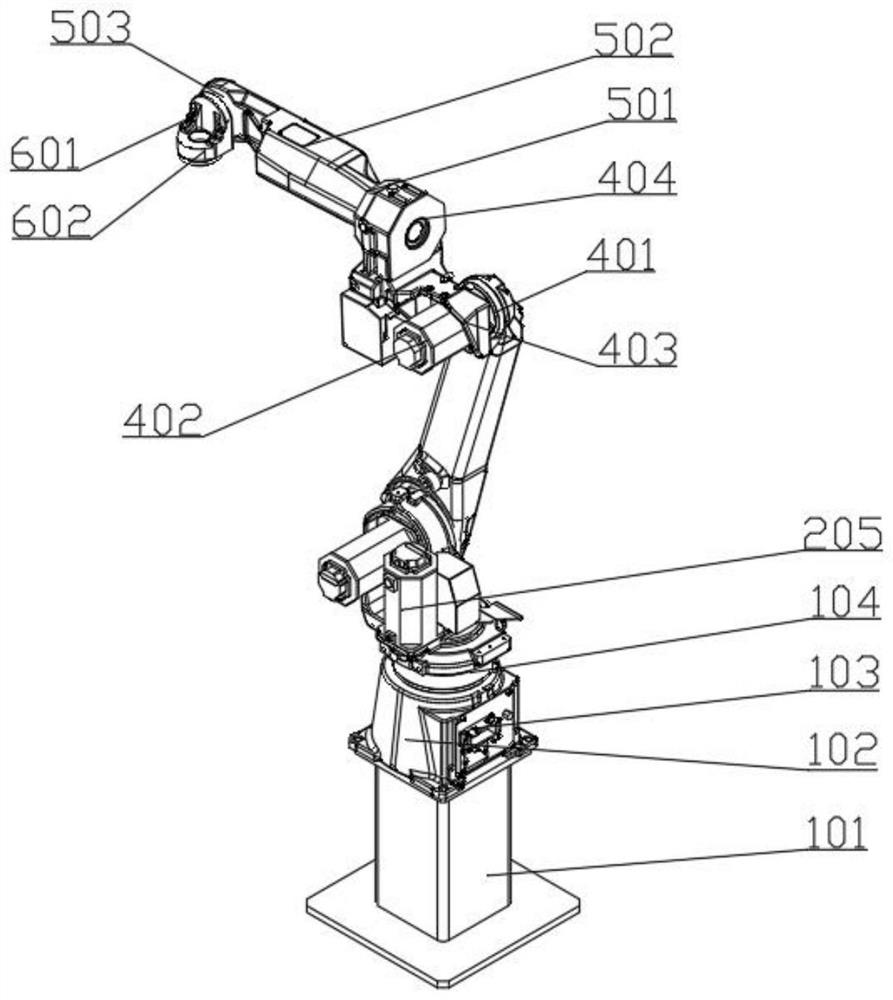

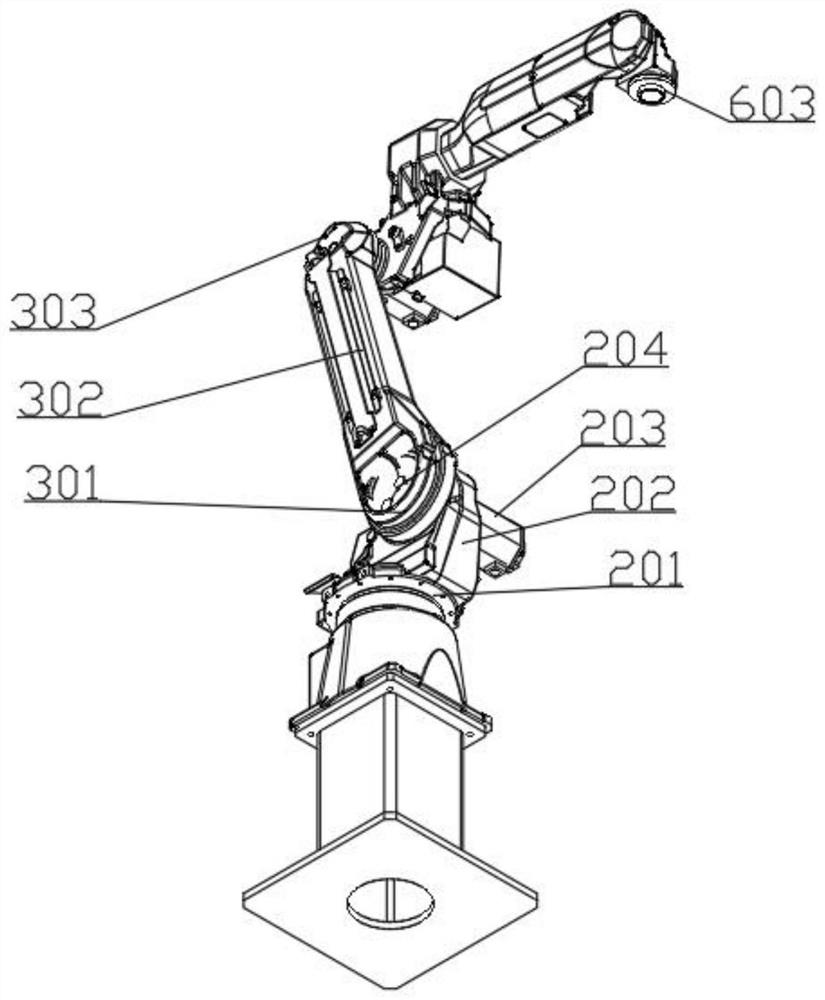

[0057] Such as Figure 1-8 As shown, a blowing structure of a manipulator includes a supporting part, a folding part, a grasping part and an air blowing part. The air blowing part includes an opening and closing assembly 7 and multiple air blowing assemblies 9; multiple air blowing assemblies 9 are symmetrically placed on both sides of the bottom of the opening and closing assembly 7, and the opening and closing assembly 7 drives the air blowing assembly 9 to reciprocate.

[0058] The present invention includes a supporting part, a folding part, a grabbing part and an air blowing part. The supporting part provides supporting force and installation position for the invention. The folding part moves the grabbing part to a suitable grabbing position by folding and opening, and the workpiece After grabbing, the residue and debris of the workpiece are removed by gas blowing through the blowing part, and the workpiece is uniformly cooled. The blowing structure used in traditional eq...

Embodiment 2

[0068] Such as Figure 1-8 As shown, a blowing structure of a manipulator includes a supporting part, a folding part, a grasping part and an air blowing part. The air blowing part includes an opening and closing assembly 7 and multiple air blowing assemblies 9; multiple air blowing assemblies 9 are symmetrically placed on both sides of the bottom of the opening and closing assembly 7, and the opening and closing assembly 7 drives the air blowing assembly 9 to reciprocate.

[0069] The present invention includes a supporting part, a folding part, a grabbing part and an air blowing part. The supporting part provides supporting force and installation position for the invention. The folding part moves the grabbing part to a suitable grabbing position by folding and opening, and the workpiece After grabbing, the residue and debris of the workpiece are removed by gas blowing through the blowing part, and the workpiece is uniformly cooled. The blowing structure used in traditional eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com