Environment-friendly production process for chemical bulk drugs

A production process and technology of chemical raw materials, which is applied in the field of environmental protection production process of chemical raw materials, can solve problems such as easy generation of dust, influence on output, and inability to effectively realize quantitative packaging, so as to save power, solve dust problems, and achieve synchronous movement effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

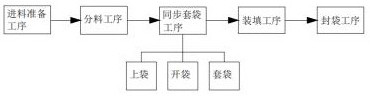

[0060] like Figure 1 to Figure 3 Shown, a kind of environmental protection packaging production process for chemical raw materials, comprises the following steps:

[0061] Step 1, the feeding preparation process, the raw material is continuously conveyed to the raw material box 2 by the feeding equipment through the sealed pipeline pumping;

[0062] Step 2, material distributing process, a filling mechanism 4 is arranged under the raw material box 2 to sequentially distribute the raw materials into each sub-packing barrel 73 in the dispensing mechanism 7, and the filling mechanism 4 includes a distributing component 41 and a distributing component 42 , the distribution assembly 41 quantitatively obtains raw materials one by one from the raw material box 2, and the distribution assembly 42 is driven by the distribution barrel 73 to transport the raw materials in the distribution assembly 41 to the distribution barrel 73;

[0063] Step 3, synchronous bagging process, a bagging...

Embodiment 2

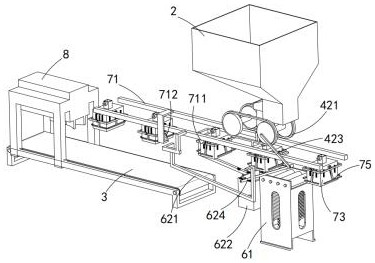

[0078] like Figure 2 to Figure 10 As shown, an automatic production equipment for chemical raw materials, including a raw material box 2 and a transfer conveyor belt 3 arranged under the raw material box 2, also includes:

[0079] Filling mechanism 4, described filling mechanism 4 is arranged on the below of described raw material box 2, and described filling mechanism 4 comprises distribution assembly 41 and cloth assembly 42, and described distribution assembly 41 obtains quantitative amount from described raw material box 2 Raw materials, the cloth assembly 42 drives the distribution assembly 41 to move to output the raw materials;

[0080] Subpackage mechanism 7, described subpackage mechanism 7 is arranged between described raw material box 2 and transfer conveyer belt 3, and described subpackage mechanism 7 comprises conveying line 71 and subpackaging barrel 73, and described subpackaging barrel 73 is in described There are a plurality of equidistant arrays on the conv...

Embodiment 3

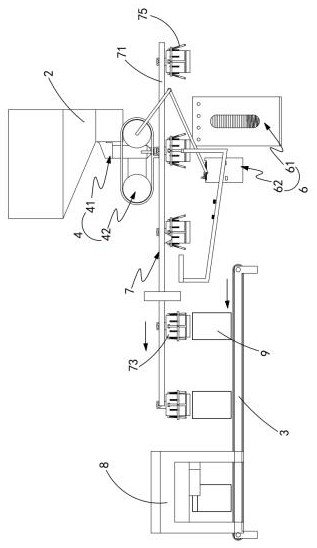

[0100] Figure 11 It is a schematic structural view of an automatic production equipment for a chemical raw material medicine of the present invention; as Figure 11 As shown, the components that are the same as or corresponding to those in Embodiment 2 use the corresponding reference numerals as in Embodiment 2. For the sake of simplicity, only the differences from Embodiment 2 will be described below. The difference between this embodiment 3 and embodiment 2 is:

[0101] Such as Figure 11 As shown, in this embodiment, the free end of the clamping rod 751 is provided with a needle 753 , and the side wall of the sub-packaging barrel 73 is provided with a pinhole plate 754 , and the pinhole plate 754 corresponds to the needle 753 one by one.

[0102] It should be noted that the corresponding cooperation between the pinhole plate 754 and the pricking needle 753 enables the clamping rod 751 to firmly clamp the material bag on the sub-packaging barrel 73 .

[0103] work proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com