Cuprous sulfide nano antibacterial agent, preparation method and application thereof

A nano-antibacterial agent, cuprous sulfide technology, applied in the field of cuprous sulfide nano-antibacterial agent and its preparation, can solve the problems of large particle size, high equipment requirements, narrow particle size distribution, etc., and achieves low cost, broad application prospects, Simple effect of experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

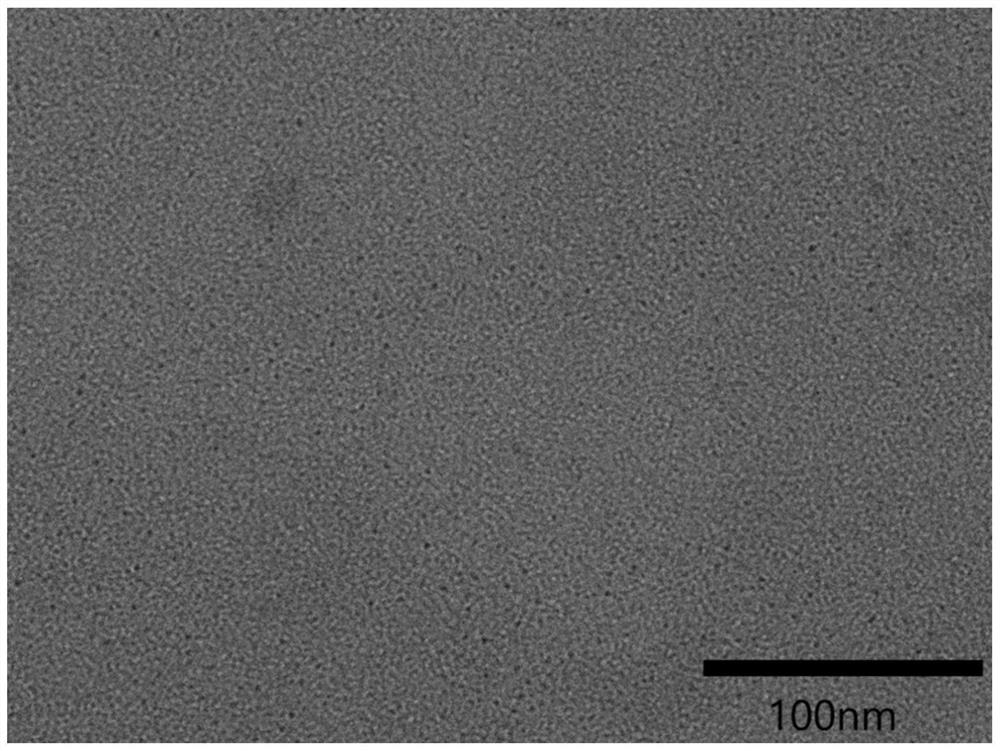

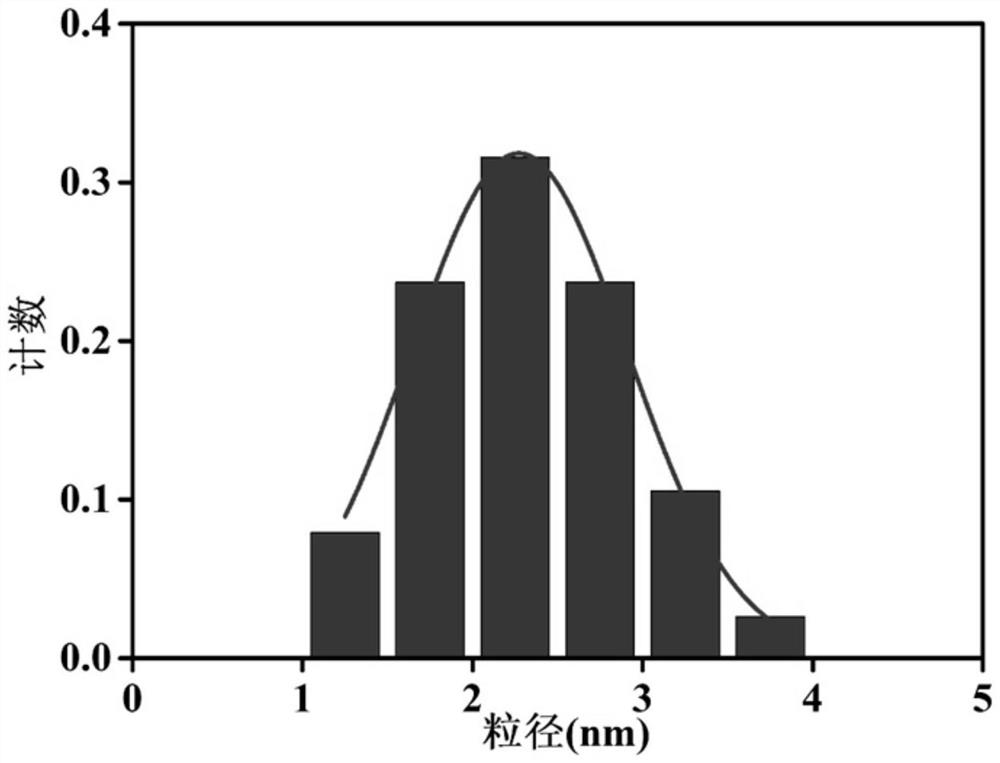

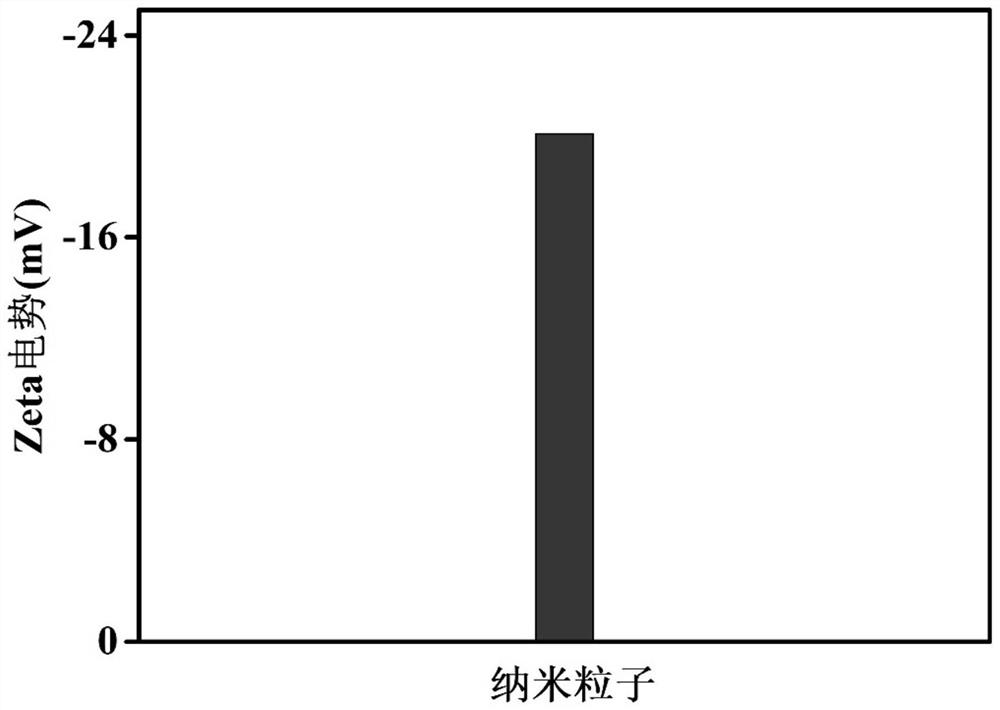

[0035] The invention discloses a preparation method of a cuprous sulfide nano antibacterial agent, the preparation method comprising: performing a first contact reaction on copper nanoparticles and an etchant to obtain the cuprous sulfide nano antibacterial agent; wherein, the The average particle size of the copper nanoparticles is 2-6nm, the valence state of the copper element in the copper nanoparticles contains positive divalent, and the etchant is selected from at least one of reduced glutathione, cysteine and serine. A sort of.

[0036] In the present invention, the consumption of described copper nanoparticles and etchant is not specifically limited, but in order to make this cuprous sulfide nano antibacterial agent have more excellent antibacterial property, preferably, described copper nanoparticles and etching The weight ratio of the agent is 1:3-1:12.

[0037] In the present invention, the conditions of the first contact reaction are not specifically limited, but...

Embodiment 1

[0051] Step 1: the ascorbic acid AA that takes 0.023mmol (4mg) is dissolved in the water of 2mL to obtain ascorbic acid solution, in the ascorbic acid solution, add the NaOH solution of 1mol / L until the pH of ascorbic acid solution is close to 14 (making the pH of the mixture 1 finally obtained is 7), then slowly drip the ascorbic acid solution into 3mL of CuCl 2 Solution (concentration is 4.2mg / mL, containing 0.093mmol CuCl 2 ), stirred at 25° C. for 30 min to prepare mixture 1.

[0052] Step 2: Add 0.7mL of the prepared mixture 1 (washed by centrifugation, dried and weighed on an electronic balance to obtain 10.2mg of copper nanoparticles) into 4mL of reduced GSH aqueous solution (50mmol / L, containing 61.4mg of reduced GSH), and stirred at 25°C, as the stirring proceeded, a white precipitate slowly appeared, and was stirred for 1h. After the reaction finishes, it is centrifuged and washed with 8000rpm for 10min, then washed 3 times with ethanol (75% by volume), and the pre...

Embodiment 2

[0054] Carry out according to the method for embodiment 1, only difference is, in step 1, ascorbic acid solution is adjusted pH by the NaOH solution of 1mol / L until the pH of ascorbic acid solution is close to 14 (so that the pH of final mixture 1 is 8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com