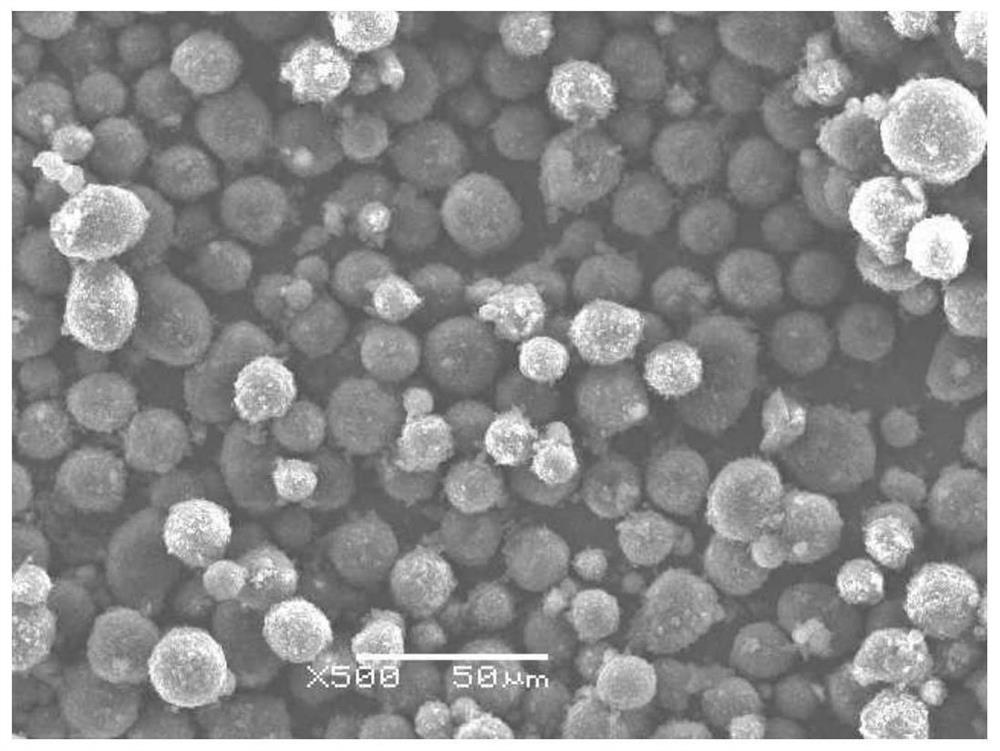

Preparation method of nucleating agent for mesocarbon microbeads

A technology of mesocarbon microspheres and nucleating agent, which is used in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by selective extraction, and processing tar pitch/petroleum pitch/natural pitch by heating It can solve the problems of difficult particle size control, low yield of mesocarbon microspheres, etc., to achieve stable product quality, increase the chance of polycondensation into spheres, and optimize the thermal polycondensation reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the nucleating agent of mesocarbon microspheres is to raise the temperature of low-temperature coal tar pitch in the polymerization reactor from normal temperature to 360°C at 3°C / min, and stay at constant temperature for 2h to obtain nuclei-rich pitch; wash oil and paraffin oil by 1 The mass ratio of : 5 is used to make a mixed solvent, and the mixed solvent and nuclear-enriched asphalt are fully mixed in the oil mixing tank according to the agent-oil ratio of 1: 1. The mixing temperature is 80 ° C, the time is 1.5 h, and the stirring speed is 80 rad / min; mix well Finally, stop stirring, raise the temperature to 120°C and let it stand for 1 hour, and obtain a nuclear-rich solvent oil with a yield of 30% from the bottom of the mixing tank; distill the nuclear-rich solvent oil in a fractionation tower, and the distillation condition is a tower bottom temperature of 380°C , the temperature at the top of the tower is 260°C, the vacuum degree is 0.0...

Embodiment 2

[0030] Raise the temperature of high-temperature coal tar pitch in the polymerization reactor from room temperature to 340°C at 5°C / min, and stay at constant temperature for 1 hour to obtain nuclear-rich pitch; make a mixed solvent of wash oil and kerosene at a mass ratio of 1:1.5, press the agent oil The ratio is 0.5:2, fully mix the mixed solvent and nuclear-rich asphalt in the oil mixing kettle, the mixing temperature is 120°C, the time is 2h, and the stirring speed is 100rad / min; after mixing evenly, stop stirring, raise the temperature to 120°C and let it stand 8h, get the nuclei-enriched solvent oil with a yield of 40% from the bottom of the mixing tank; distill the nuclei-enriched solvent oil in a fractionation tower, the distillation conditions are 400°C at the bottom of the tower, 260°C at the top of the tower, and a vacuum of 0.07MPa, and recover them separately Kerosene and washing oil are obtained from the bottom of the fractionation tower as a nucleating agent. Th...

Embodiment 3

[0032] The heavy oil directly liquefied from coal is heated from normal temperature to 295°C at 5°C / min in a polymerization reactor, and then kept at a constant temperature for 3 hours to obtain nuclei-rich pitch; the coking light oil and petroleum ether are formulated into a mixed solvent at a mass ratio of 1:1 , according to the agent-oil ratio of 5:2, fully mix the mixed solvent and nuclear-rich asphalt in the oil mixing kettle, the mixing temperature is 60°C, the time is 3h, and the stirring speed is 120rad / min; after mixing evenly, stop stirring and raise the temperature to 130 ℃ and stand for 4 hours, the yield of 10% nuclei-enriched solvent oil is obtained from the bottom of the mixing tank; the nuclei-enriched solvent oil is distilled in a fractionation tower, the distillation conditions are 340°C at the bottom of the tower, 220°C at the top of the tower, and a vacuum of 0.09 MPa, recover light oil and petroleum ether respectively, and obtain the nucleating agent from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com