Preparation equipment of high-temperature-resistant steel material

A technology of high temperature resistance and equipment, which is applied in the field of high temperature resistant steel material preparation equipment, can solve the problems of strengthening the performance of the pipe body, the steel material cannot be directly cooled and formed, and is prone to bending, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Figure 1 to 6 Looking:

[0029] The present invention provides an apparatus for preparing high-temperature steel material,

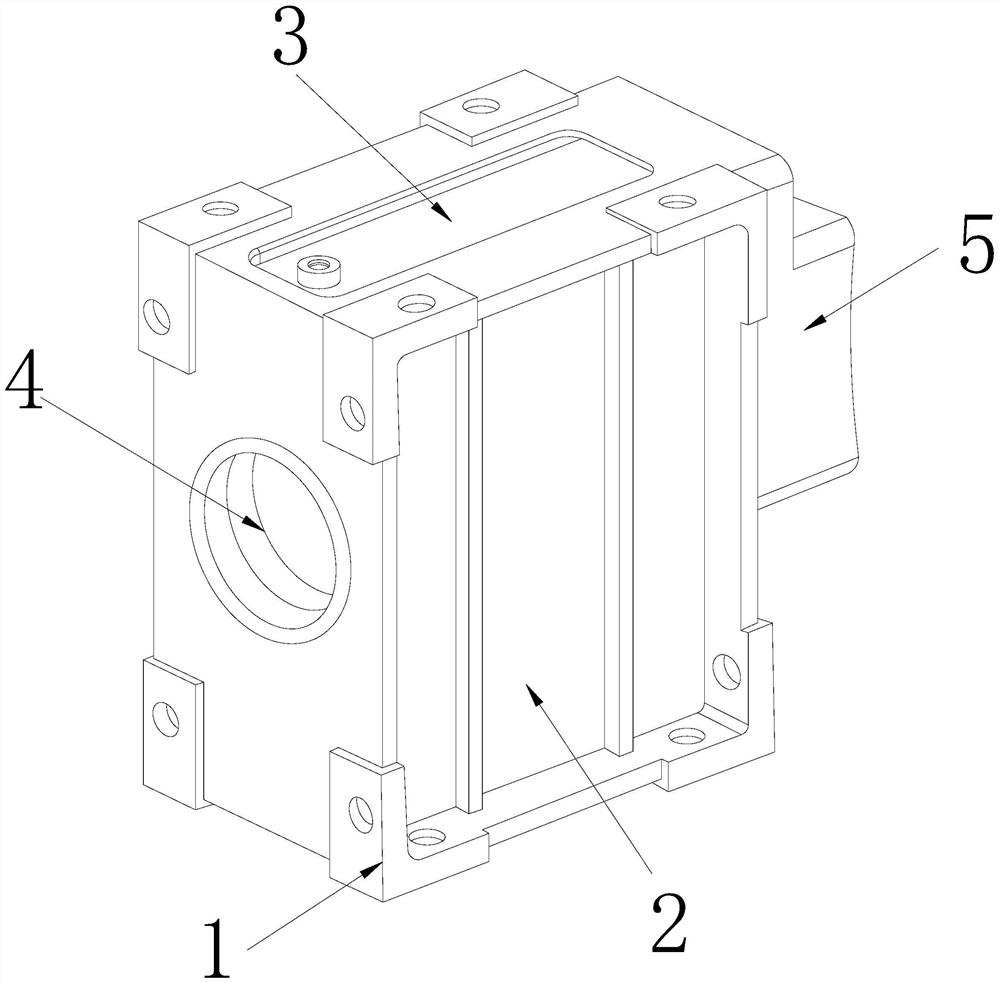

[0030] The structure comprises a positioning block, grown tank 2, the distribution tank 3, into the feed end 4, 5 export the positioning block 1 and grown tank 2 is fixedly connected to the distribution tank 3 is fitted to quench the upper end of the mixing tank 2, a feed terminal 4 and the side edge integrally grown tank 2, the exporter 5 communicates with the feed end 4.

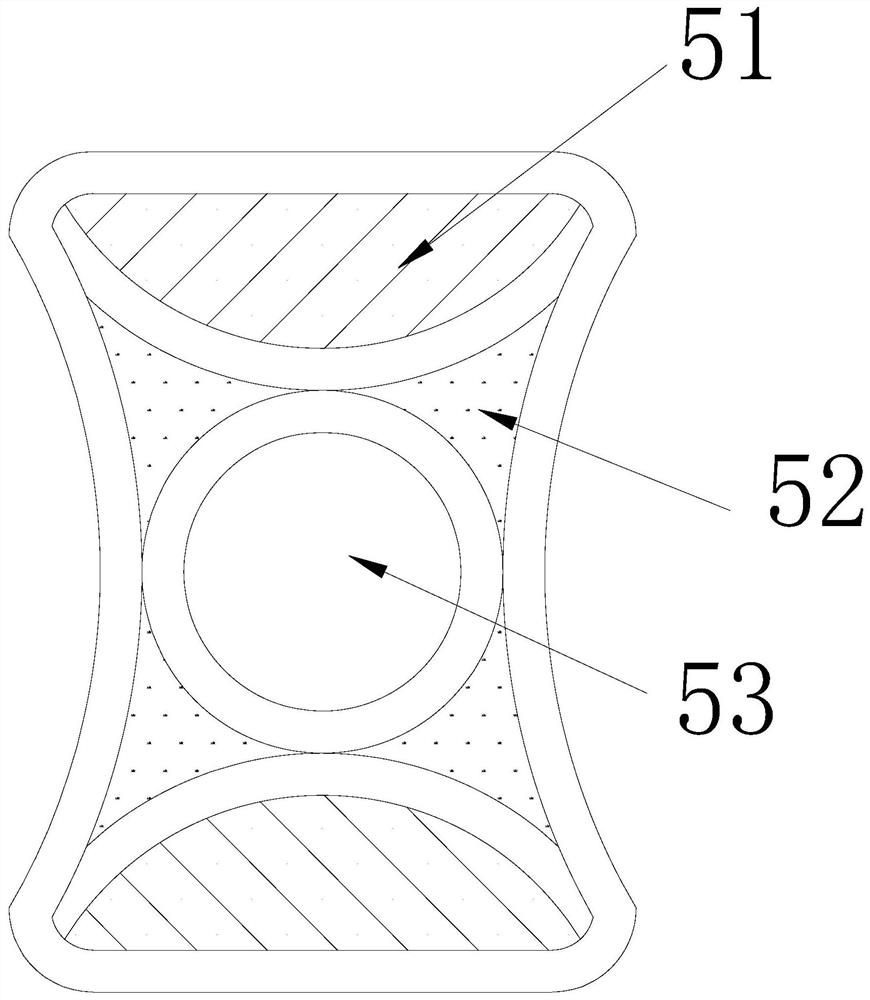

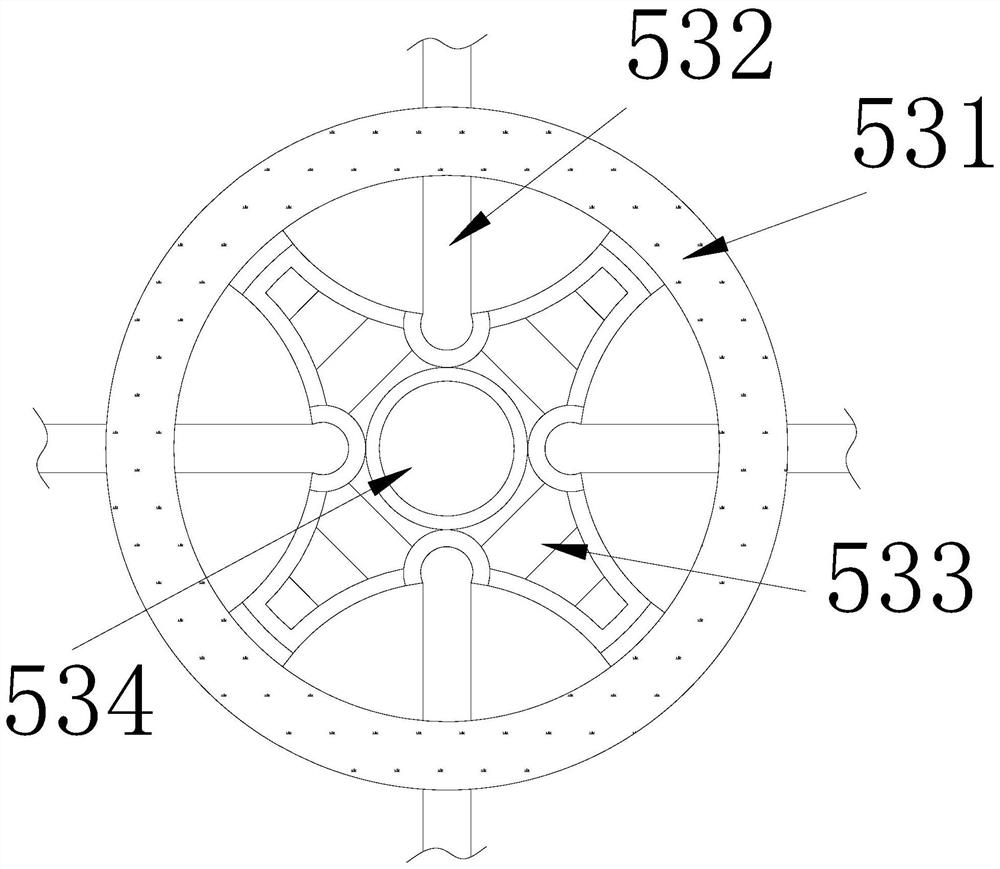

[0031] The derivation unit 5 is provided with a solid block 51, the mounting groove 52, grown up passage 53, the solid block 51 and the mounting groove 52 is fixedly connected to the passage 53 grown in the mounting groove 52 is embedded in the solid upper and lower mounting block 51 at both ends is provided with a total of two grooves 52 and form a symmetrical state, the position of the solid block 51 by its number and symmetry states can effectively be grown passage 53 for posi...

Embodiment 2

[0039] Figure 7 to 9 Looking:

[0040] The present invention provides a preparation apparatus for high-temperature steel material,

[0041] Its structure includes the storage body C1, the introduction hole C2, the permeate layer C3, the sides of the storage body C1 and the introduction hole C2, the permeate layer C3 is embedded in the lower end of the introduction hole C2 and Phase, the storage body C1 is provided with four pieces and is a communication, the storage body C1 can achieve all the storage of all the coolants to achieve all-round cooling of the steel.

[0042] Wherein, the storage body C1 is provided with a guide hole C11, a stacked groove C12, a discharge terminal C13, and the guide hole C11 communicates with the stacked groove C12, the discharge end C13 embedded in the side edge of the stacked groove C12, the stacked groove. The inner wall of the C12 is made of stainless steel, and the stacked groove C12 can effectively prevent the rust phenomenon produced by the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com