Coal-fired boiler flue gas and steam combined heat storage deep peak shaving system and operation method

A coal-fired boiler and steam technology, which is applied in steam generation, steam engine installations, steam generation installations, etc., can solve the problems of limiting the minimum output of coal-fired generating units, high boiler discharge temperature, energy loss, etc., and improve energy utilization efficiency. With the economy of the unit, the effect of increasing the variable load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

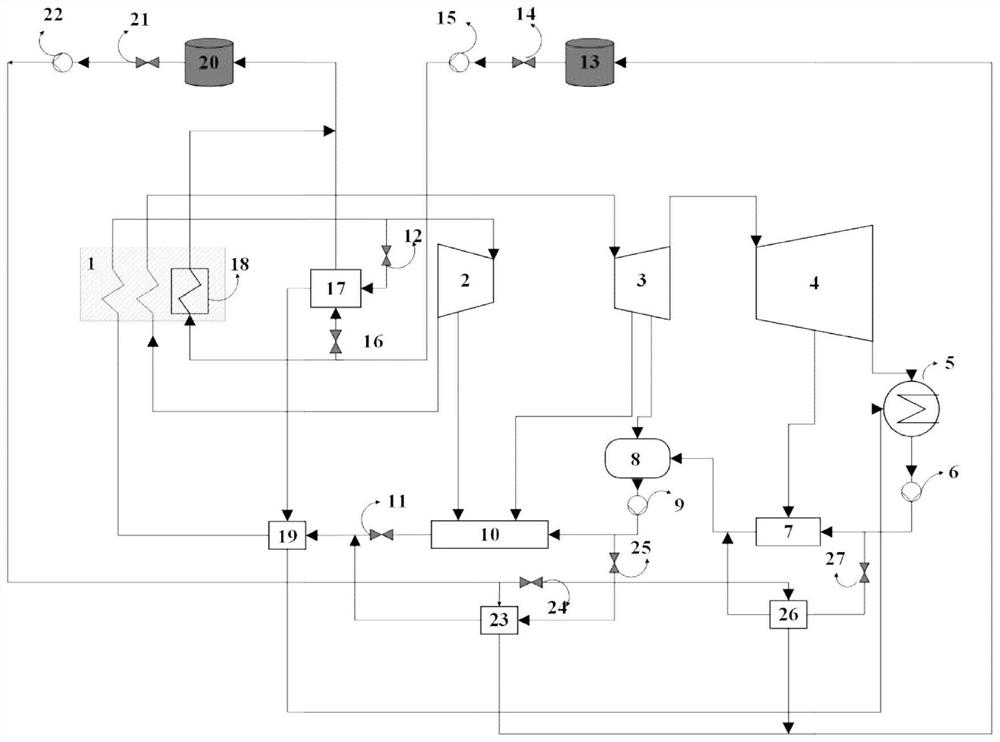

[0020] Such as figure 1 As shown in the present invention, a coal-fired boiler flue gas and steam combined heat storage deep peak-shaving system includes a coal-fired power unit thermal system and a heat storage system coupled therewith, wherein:

[0021]The thermal system of the coal-fired generating set includes a boiler 1, a steam turbine high-pressure cylinder 2, a steam turbine medium-pressure cylinder 3, a steam turbine low-pressure cylinder 4, a condenser 5, a condensate pump 6, a low-pressure heater 7, a deaerator 8, and a feed water pump 9 , high-pressure heater 10, high-pressure heater outlet regulating valve 11 and main steam diverter valve 12, the second heat storage medium heater (18) is arranged in the flue of described boiler (1); the superheated steam outlet of boiler 1 and The steam inlet of the high-pressure cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com