Horizontal impact testing machine and testing method for impact resistance of glass

A technology of impact resistance and impact testing machine, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of test personnel injury, increase testing cost, large laboratory space, etc., achieve the safety guarantee of test personnel and reduce testing cost , the effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

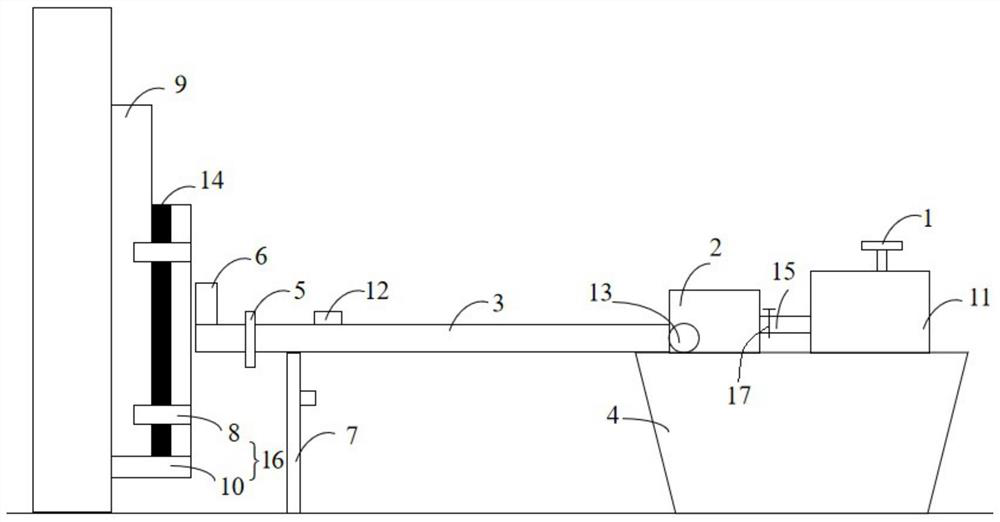

[0036] Embodiments of the present invention provide a glass impact resistance level impact testing machine, such as figure 1 As shown, it includes a control box 1, an air compressor 11, an air storage tank 15, a steel ball chamber 2, a guide slide 3 and a glass sample support frame 16, wherein:

[0037] The output end of the air compressor 11 communicates with the air inlet of the air storage tank 15 , and the air compressor 11 provides compressed air for the air storage tank 15 .

[0038] The steel ball chamber 2 is used to hold the steel balls 13. Different tests require the steel balls 13 to have different specifications such as quality and volume. Steel balls of different specifications in the present invention are applicable and can be selected according to different test requirements.

[0039] The air outlet of the air storage tank 15 is connected with the steel ball bin 2, and the compressed air in the air storage tank 15 provides initial kinetic energy for the steel ba...

Embodiment 2

[0061] An embodiment of the present invention provides a method for testing using the glass impact resistance level impact testing machine described in Embodiment 1, the method comprising:

[0062] S1: Fix the glass sample 14 to be tested vertically on the glass sample support frame 16, and adjust the upper and lower positions of the glass sample support frame 16 so that the center point of the glass sample 14 is aligned with the exit of the guide slide 3.

[0063] This step is used to install the glass sample 14 to be tested. The distance between the outlet of the guide slide 3 and the surface of the glass sample 14 is adjustable, and glass samples 14 of different thicknesses can be installed. During installation, it is necessary to adjust the distance between the surface of the glass sample 14 and the exit of the guide slide 3 according to the thickness of the glass sample 14 to be prepared, and adjust the glass sample support frame 16 so that the center point of the glass sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com